Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

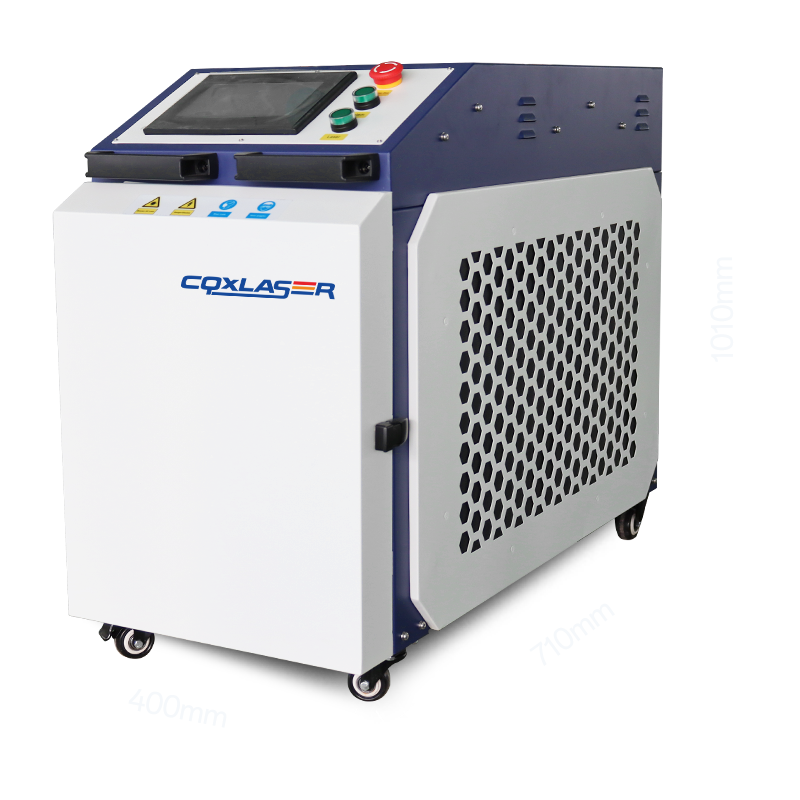

PW-SERIES 1-3KW

Portable laser welding machine is a new generation of laser welding products, integrated design, beautiful appearance, stable performance, easy installation and operation, high safety.

It has fast welding speed, high efficiency and good welding effect. With the characteristics of long using life and being environmental friendly, it can be widely used in the welding of kitchen appliances, door and window guardrails, stairs and elevators, stainless steel furniture, sheet metal, billboards, craft gifts, car repairs, engineering, automobile manufacturing, rail transit and aerospace.

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

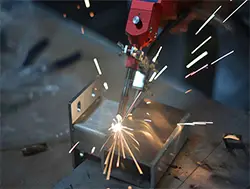

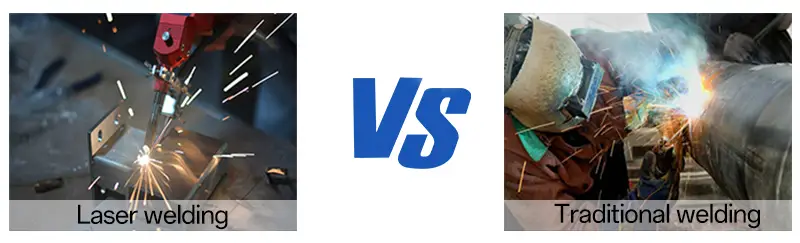

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

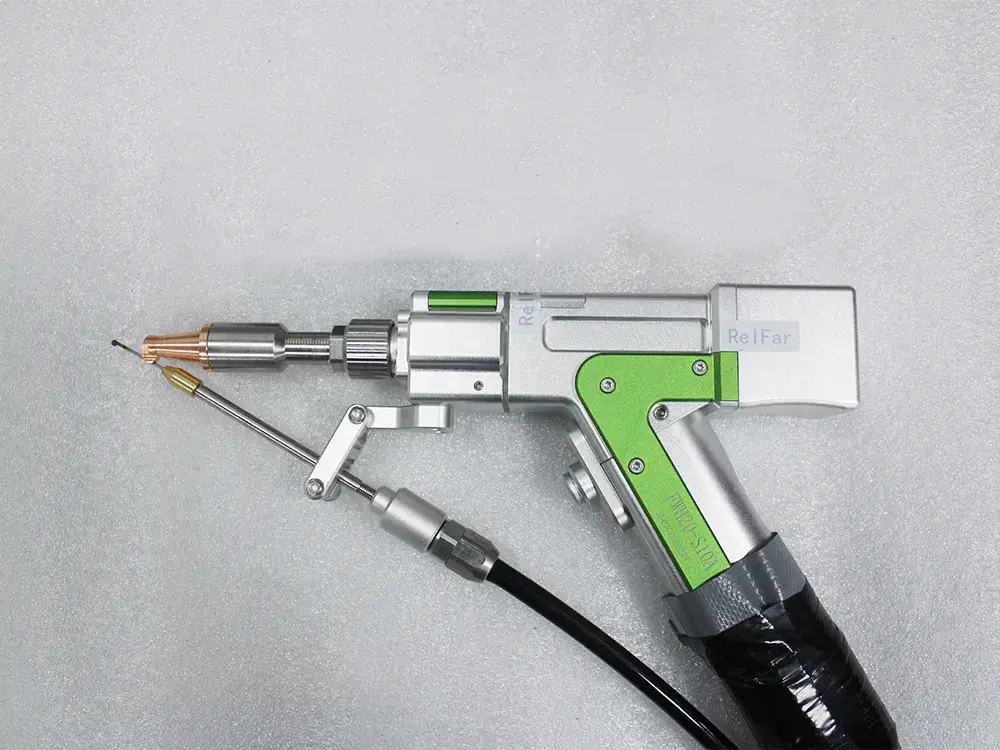

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

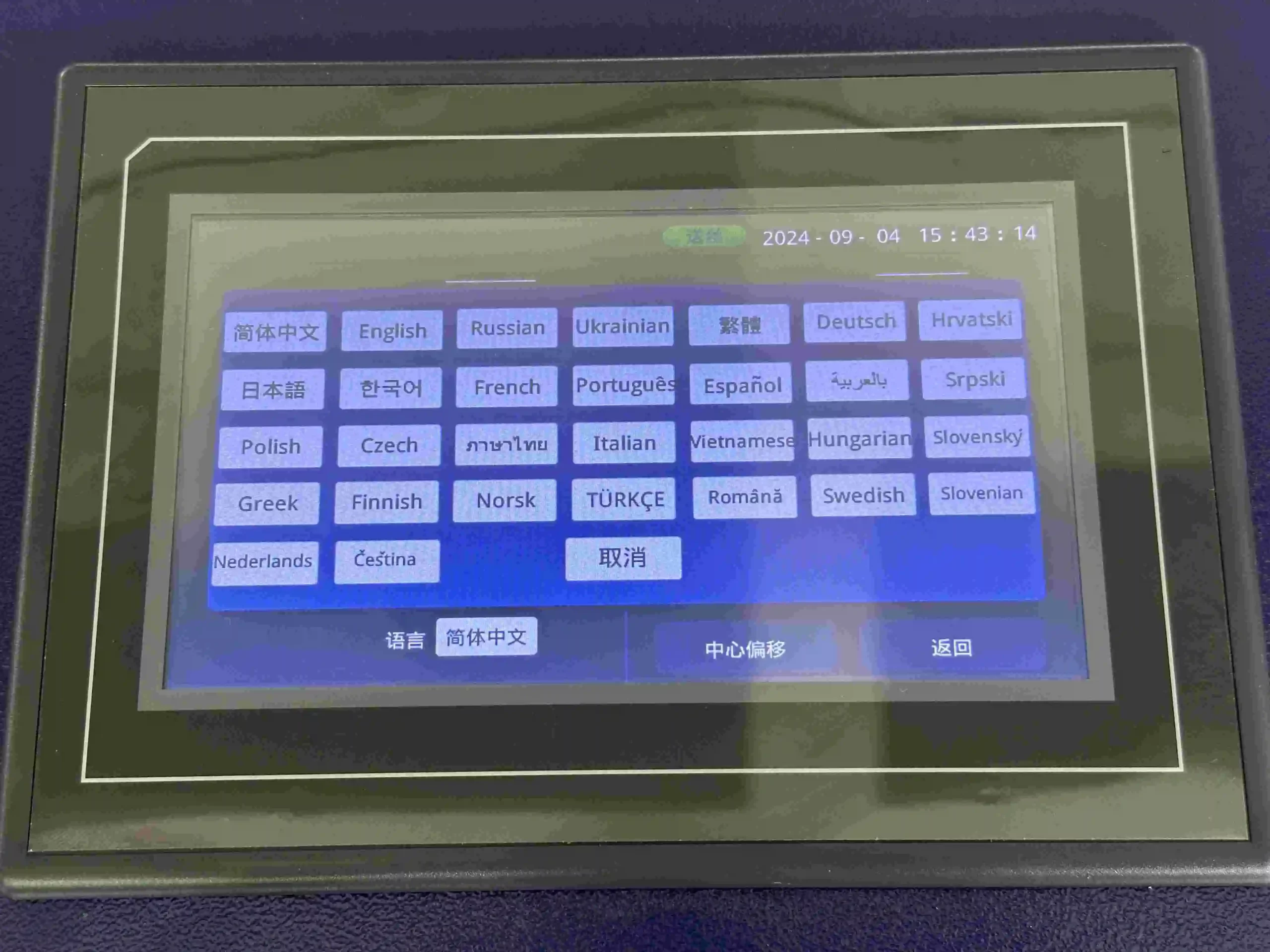

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

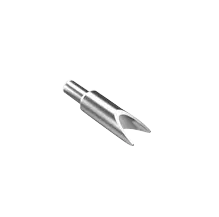

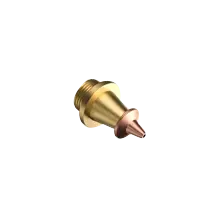

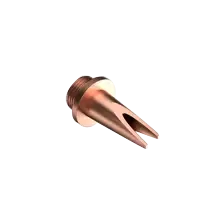

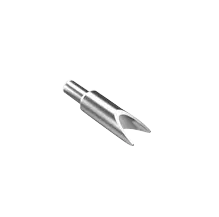

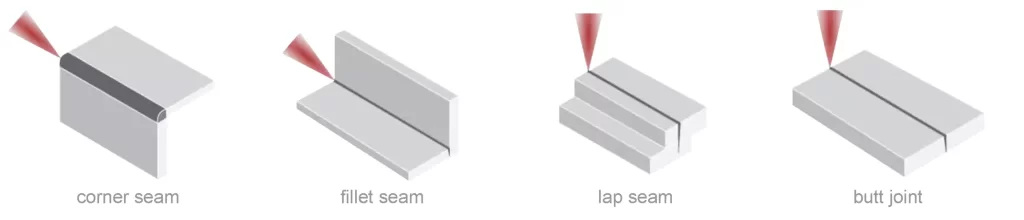

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| -PERFORMANCE TECHNICAL PARAMETERS- | ||||

|---|---|---|---|---|

| Power | 1000W | 1500W | 2000W | 3000W |

| Laser Wavelength | 1070nm | |||

| Laser Type | Continuous | |||

| Cooling mode | Water Cooling | |||

| Voltage | 220V, 50/60Hz | 380V, 50/60Hz | ||

| Welding Thickness (Single side) | 0.5-3mm | 0.5-4mm | 0.5-5mm | 0.5-8mm |

| Welding Speed | 0-120mm/s | |||

| Welding Gap | ≤0.5mm | |||

| Laser Lifetime | 100000h | |||

| Laser Source | MAX/Raycus/IPG/BWT | |||

| Laser Head & Control System | Sup/Qilin/Relfar/Raytools | |||

| Fiber Cable Length | 10m, Customized 20m max | |||

| Working Required Temperature | 10-35℃ | |||

| Machine Dimension | 1010*400*710mm | 1140*530*1040mm | ||

| Weight | 130kg | 150kg | ||

-PERFORMANCE TECHNICAL PARAMETERS- |

||||

| 1 Portable Handheld Laser Welding Machine | ||||

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Machine Dimension | 860*410*700mm | 1140*530*880mm | ||

| Weight | 130kg | 150kg | ||

| 2 Portable Handheld Laser Welding Machine | ||||

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Machine Dimension | 890*400*760mm | 1100*450*790mm | 1270*520*1070mm | |

| Weight | 130kg | 150kg | 180kg | |

When considering the purchase of a welding solution that offers precision, accuracy, and versatility, the handheld laser welding machine is a top contender. The handheld laser welding machine price varies depending on various factors, but its benefits often justify the investment. These machines fuse metal parts with a highly concentrated light beam, allowing for precise and accurate welding, making them ideal for manufacturers, fabricators, and repair professionals who need the flexibility to make on-site repairs. Whether your work involves aerospace, medical device manufacturing, jewelry making, automotive, or general fabrication, a portable laser welding machine can handle any project.

What Makes Portable Laser Welding Machines Unique and Worthwhile Investments

Handheld laser welding machines can weld various materials, such as steel, aluminum, titanium, alloys, and even some plastics. These machines perform welds quickly and efficiently, making them suitable for large-scale production runs or use in high-volume manufacturing environments. Some portable handheld laser welding machines are automated, resulting in consistent and repeatable results while reducing the need for skilled labor. These machines can be programmed to perform complex welding patterns, increasing the welding process’s efficiency and consistency.

How Thick Can a Laser Welding Machine Weld?

The thickness that a laser welder can handle varies depending on the specific type of laser welder and the materials being welded. Generally, laser welding is most effective for welding thin materials, typically less than 1/8 inch (3mm) thick. For thicker materials, fiber laser welding can weld up to 1/4 inch (6mm) thick with good quality.

Portable Laser Welding Machine Buying Guide

When selecting a handheld laser welding machine, consider the materials you will be working with and choose a machine capable of welding those materials. Some machines, such as fiber laser welding machines for aluminum welding, are better suited for specific materials. Consider the thickness of the materials you’ll be welding and select a machine with sufficient power. A more powerful laser welding system can weld thicker materials and perform faster. Choose a machine that is simple to use and program. Some machines are completely automated, making them more user-friendly. Look for a laser welding machine with a good warranty and manufacturer customer support.

Screen-Equipped Welding Gun

The handheld welding gun features a display screen for real-time monitoring and adjustment of welding parameters. Multiple nozzles are included to cover any 0.8-1.2 mm wire welding, cutting, or cleaning needs. Additionally, you can adjust the language of the display, making it accessible for various users.

User-Friendly Controls

The intuitive touchscreen panel simplifies adjustments for air assist, laser, and wire feeding. The responsive welding gun throttle enables quick laser and wire discharge, ensuring a clean and efficient welding process without sticking.

Features of Handheld Laser Welding Machines

Applications

The laser welding head comes with multiple nozzles of different types, suitable for wire diameters ranging from 0.8 to 1.2 mm, wire-free welding, cleaning, and cutting. This versatility meets welding requirements for both inside and outside corners.

About Laser Welding Machine Price

A laser welding machine is a tool that uses an intense light beam to weld together two separate pieces of metal or other materials. The beam produced by the machine comprises focused, high-intensity rays of laser energy directed at the welded part. Laser welding technology is common in various industrial processes to join components that are difficult to weld by other methods.

Functions of a Laser Welding Machine

Laser welding machines can weld materials at high speeds, typically much faster than traditional welding techniques. This speed ensures intricate, precision welds, which are more robust and durable than those produced by conventional methods. In addition, a tool with a valued handheld laser welding machine price provides higher quality and greater efficiency than traditional methods.

Features of a Laser Welder

Laser welding machines come in various sizes and shapes, including small laser welding machines, and handheld laser welders. Many models are highly automated, providing operators with higher speed, increased efficiency, and safety when welding. Laser welding machines offer higher precision while functioning in an accurate and reliable process.

Uses of Laser Welding Machines

Laser welding machines can weld various materials, such as aluminum, stainless steel, and titanium. These machines are popular in many industrial applications, such as automotive, aerospace, and medical device manufacturing. They are also used in welding repair, automotive restoration, dentistry, and consumer electronics.

Power Diversity and Precision

The handheld laser welding machine price is influenced by power. There are typically three types of power: 1000W, 1500W, and 2000W. The higher the power, the higher the welding speed and energy density. Handheld laser welders allow for very precise control of the welding process because the laser beam can be focused to a very small spot. This precision enables the welding of tiny components as well as complex or delicate welding tasks.

Energy Saving and Environmental Protection

Laser welding machines have high energy utilization rates, which can reduce energy consumption while minimizing the heat-affected zone, making them environmentally friendly.

Flexibility

Handheld laser welders can weld a variety of materials, including metals, plastics, and composites. They can even effectively join dissimilar materials that are difficult to weld with traditional welding processes.

Wide Range of Applications

Laser welders are suitable for welding various metal materials and different thicknesses, with a wide range of applications in industries such as automotive manufacturing, aerospace, medical equipment, and more.

Additional Features

What is the Use of Handheld Laser Welders?

Safety Measures for Laser Welding Machines

Factors Affecting Laser Welding Machine Price

Maintenance of Laser Welders for Sale

Conclusion

The handheld laser welding machine price reflects its numerous advantages, including high efficiency, precision, and versatility. These machines are poised to replace traditional welding methods in many applications, offering long-term benefits in terms of speed, quality, and cost savings. Whether you are a professional welder or a business looking to improve your welding processes, investing in a handheld laser welding

machine can provide significant returns.