Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

PL-SERIES 50-300W

The pulse laser cleaning machine uses short laser pulses to evaporate surface contaminants or coatings without causing thermal or mechanical damage to the substrate. It is suitable for cleaning sensitive materials and precision parts without causing damage.

Lightweight Design: The backpack design improves portability, making it easy to carry and use anywhere. Even a thin girl can carry it easily.

Efficient: The pulse laser cleaning system is stable,It can be targeted at specific areas for precise cleaning. and the mobile laser rust removal works quickly, effectively improving the cleaning time.

Damage to the surface

Heavy pollution,

complicated waste disposal

High cost,

damage to the surface

Limited size of the

product being ceaned

| Comparison Items | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Rust Removal | Ultrasonic Cleaning |

|---|---|---|---|---|---|

| Working Principle | Laser | Chemical Cleaner | Sandpaper/Grinding Wheel | Dry Ice | Cleaning Agent |

| Contactless | Yes | No | No | Yes | No |

| No damage to workpiece | Yes | No | No | Yes | Yes |

| Cleanliness | High | Uneven | Uneven | Uneven | Small cleaning range |

| Cleaning Efficiency | High | Low | Low | Medium | Medium |

| Accuracy | High accuracy (Controllable) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Can't be specified (range cleaning) |

| Environmental Friendly | Yes | No | No | Yes | No |

| Manual Operation | Simple | Complex | Protective measuresrequired | Simple | Simple |

| Consumables | No | Yes | Yes | Yes | Yes |

The laser rust removal qun is ightweight and easy to carry, t weighs only 0.75 kg, ensuring that users can stay energetic evenwhen working for a long time.The laser cleaning gun is equipped with a professional high-performance lasellens with fast scanning speed and high precision, meeting the needs of various laser cleaning applications.

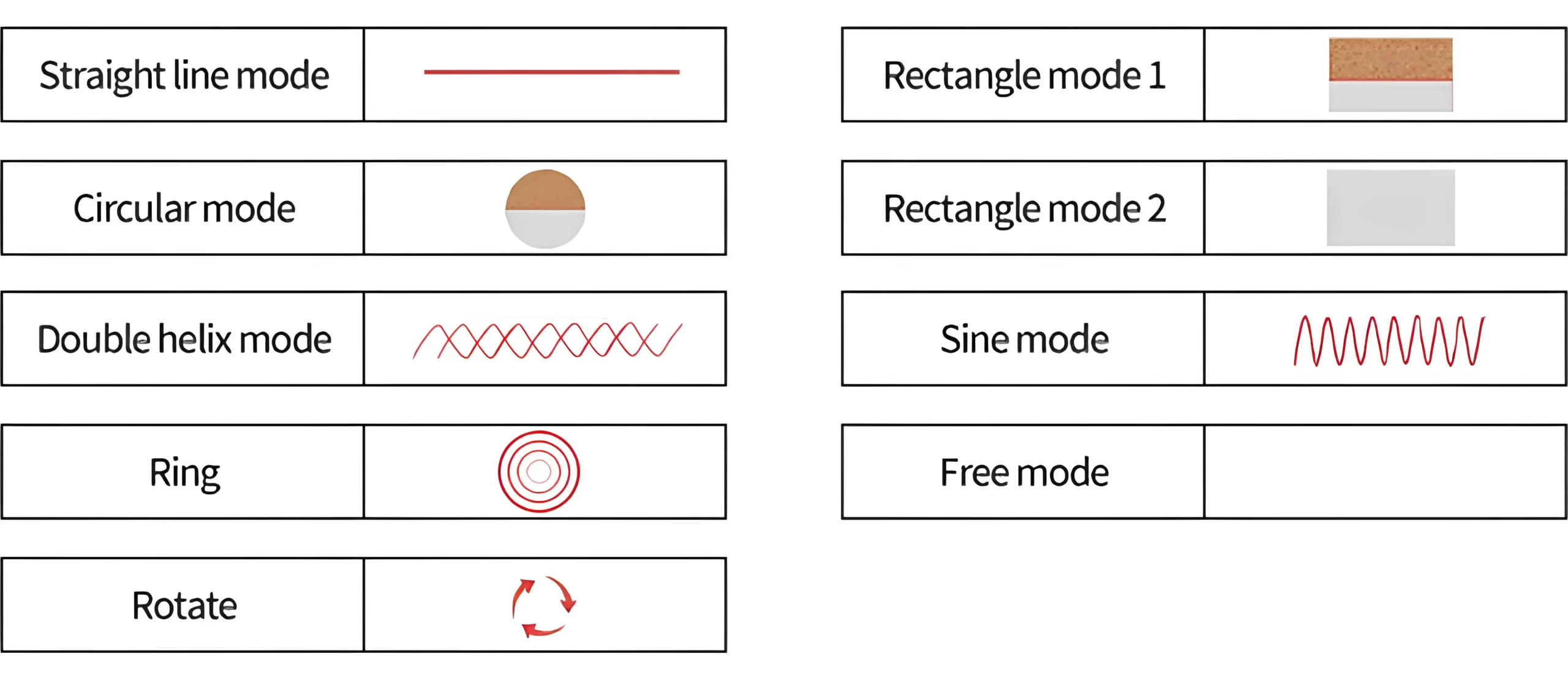

Choosing the right cleaning mode ensures that marks are minimized and the appearance and quality of the product are improved.The right cleaning mode is especialy important for automotive manufacturing, aerospace, electronics and other related industries

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Our laser rust remover has a wireless control screen that can be conveniently tied to the wrist. Users can control the laser rust remover without being confined to a fixed position. This design enhances operational flexibility and improves productivity.

Easier to maintain. When the battery fails or needs to be replaced, the operator

can directly replace the battery without waiting for professional repairs.

The removable battery design also ensures that the laser cleaner is easy to carry and move.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| -PERFORMANCE TECHNICAL PARAMETERS- | ||||

|---|---|---|---|---|

| LaserPower | 50W | 100W | 200W | 300W |

| voltage | StandardAC220V±10%,50/60Hzpoweradapter(outputDC48V) | |||

| Optional additional battery 50W continuous operation for 2h | Optional battery100W continuous operation for 80-90 minutes | Optional 200w battery for 80 minutes | Optional 300w battery for 60 minutes | |

| Lasertype | FiberLaser | |||

| Repetitiorfrequency | 45-170KHZ | 20-200KHz(adjustable) | l-3000KHz(adjustable) | l-3000KHz(adjustable) |

| Fiberlength | 1.5M | |||

| Coolingtype | AirCooling | |||

| Speed | 12000mm/s | 30000mm/s | ||

| CleaningRange | 0-100mm | 0-145mm | ||

| Size | 210*118mm/163*265mm | 213*123mm/168*339mm | 268*135mm/191.5*445mm | |

| MachineWeight | 7KG/9.6KG(Batteryincluded) | 8.5KG/12KG(Batteryincluded) | 12.5KG/17KG(Batteryincluded) | 13.5KG/18.1KG(Batteryincluded) |

| LaserHeadWeight | <0.75Kg | |||

| OperatingMode | Handheld/Automation | |||

| Power1nstability | Lessthan5% | 5% | <5% | |

| ScanMode | 8Kinds | |||

| PowerConsumption | <400W | 600W | 800W | <1100W |

| WorkingTemperature | 5°C〜40°C | |||

| WorkingEnvironmentHumidity | 80%orless | 80% | W80% | |

Imagine a cleaning solution that combines unparalleled precision, unmatched efficiency, and total eco-friendliness. A solution that can restore surfaces to their original state with laser-sharp accuracy, without damaging delicate materials or relying on harmful chemicals. This is the promise of the pulse laser cleaning machine, a cutting-edge device that has transformed surface cleaning for industries worldwide.

From removing stubborn rust on industrial machinery to restoring the beauty of centuries-old monuments, the pulse laser cleaning machine has become the go-to technology for professionals who demand the best. But what makes this device so powerful? How does it work, and why is it considered the future of industrial cleaning? In this comprehensive guide, we’ll explore everything you need to know about pulse laser cleaning machines, their benefits, applications, and why they are rapidly gaining popularity.

The rise of the pulse laser cleaning machine is no accident. Traditional cleaning methods, while effective in some cases, often come with drawbacks such as environmental harm, surface damage, and high labor costs. The pulse laser cleaning machine addresses these issues with a combination of advanced technology and practical efficiency. Here’s why it has become a game-changer:

1.Unmatched Precision and Control

Pulse laser cleaning machines deliver exceptional accuracy, allowing users to remove contaminants layer by layer without damaging the base material. This level of precision is crucial for sensitive applications, such as restoring ancient artifacts or cleaning high-value components.

2.Eco-Friendly and Chemical-Free

One of the standout benefits of pulse laser cleaning machines is their chemical-free operation. Unlike abrasive or solvent-based methods, laser cleaning relies solely on laser energy, eliminating the need for hazardous chemicals and reducing environmental impact.

3.Versatility Across Applications

Whether it’s removing rust from metal surfaces, stripping paint from industrial equipment, or cleaning delicate materials in medical manufacturing, the pulse laser cleaning machine adapts to a wide range of tasks and materials.

4.Time and Cost Savings

Although the initial investment may seem high, pulse laser cleaning machines are designed for long-term savings. They operate faster than traditional methods, reduce labor costs, and require minimal maintenance, making them a cost-effective solution.

5.No Secondary Waste

Unlike sandblasting or chemical cleaning, which produce significant waste, laser cleaning generates no secondary residues. This makes it a cleaner, safer, and more sustainable choice.

Read More

The science behind the pulse laser cleaning machine is both innovative and straightforward. Here’s a step-by-step look at how this advanced technology operates:

• Laser Emission: The machine emits short, high-energy laser pulses directed at the target surface.

• Contaminant Absorption: The contaminants on the surface absorb the laser energy, causing them to vaporize or detach.

• Controlled Removal: The machine allows for precise control of laser intensity, pulse duration, and frequency, ensuring that only the contaminants are removed while the base material remains unharmed.

• No Residue, No Waste: The vaporized contaminants are either blown away or collected through integrated systems, leaving behind a clean, residue-free surface.

This non-invasive process is what makes pulse laser cleaning superior to traditional methods, particularly for delicate or high-value surfaces.

The versatility of pulse laser cleaning machines has made them indispensable across numerous industries. Let’s explore some of the most common applications:

1.Rust and Corrosion Removal

Pulse laser cleaning machines excel at removing rust and corrosion from metal surfaces. This application is widely used in industries like automotive manufacturing, shipbuilding, and aerospace.

2.Paint and Coating Stripping

Whether it’s removing old paint from machinery or stripping coatings from parts before refurbishing, pulse laser cleaning provides a clean, damage-free solution.

3.Welding Preparation and Post-Welding Cleaning

Clean surfaces are critical for strong, durable welds. Pulse laser cleaning machines prepare surfaces by removing rust, grease, and other contaminants, ensuring high-quality welding results.

4.Cultural Heritage Restoration

Restoring historical monuments and artifacts requires precision and care. Pulse laser cleaning is a non-invasive method that removes dirt, grime, and even graffiti without damaging the original material.

5.Industrial Maintenance

Factories and production facilities use pulse laser cleaning machines to maintain equipment by removing grease, oil, and other residues that can affect performance.

6.Electronics and Semiconductor Manufacturing

The electronics industry relies on pulse laser cleaning for its ability to clean components with microscopic precision, ensuring optimal functionality without damage.

7.Medical Equipment Cleaning

In the medical field, pulse laser cleaning is used to clean surgical instruments and manufacturing tools, maintaining strict hygiene and quality standards.

Investing in a pulse laser cleaning machine requires understanding the factors that influence its cost. Here are some key considerations:

1.Laser Power and Wavelength

Higher-powered machines are capable of handling tougher cleaning tasks and larger surfaces, but they also come at a higher price. Similarly, the laser wavelength affects its compatibility with specific materials.

2.Advanced Features

Machines equipped with features such as adjustable pulse settings, real-time monitoring, and automated cleaning modes tend to be more expensive but offer greater flexibility and efficiency.

3.Portability and Design

Lightweight and compact designs with ergonomic features may increase the cost but provide significant advantages in terms of convenience and usability.

4.Brand Reputation and Warranty

Reputable brands like CQX offer high-quality machines backed by robust warranties and customer support, ensuring long-term reliability and value.

5.Application-Specific Accessories

Additional features like cooling systems, dust extraction units, and enhanced safety mechanisms can add to the overall cost but enhance functionality and ease of use.

CQX has built a strong reputation as a leader in laser cleaning technology, offering solutions that are reliable, efficient, and customizable. Here’s why CQX is the preferred choice for businesses worldwide:

1.Cutting-Edge Innovation

CQX integrates the latest advancements in laser technology, ensuring their machines deliver superior performance across all applications.

2.Customizable Solutions

Every industry has unique needs. CQX designs its machines to be adaptable, offering customizable features to suit specific requirements.

3.Exceptional Customer Support

From installation and training to ongoing maintenance, CQX provides comprehensive support to ensure customer satisfaction.

4.Affordable Quality

CQX balances affordability and quality, making advanced pulse laser cleaning technology accessible to businesses of all sizes.

Selecting the right machine requires careful consideration of your needs and applications. Here are some tips to guide your decision:

• Define Your Cleaning Requirements: Consider the type of material, level of contamination, and scale of your cleaning tasks.

• Evaluate Performance Features: Look for machines with adjustable power, precision controls, and advanced features that meet your specific needs.

• Assess Long-Term Costs: Consider the machine’s energy efficiency, maintenance requirements, and operational savings when evaluating its price.

• Request a Demonstration: Whenever possible, test the machine to see how it performs on your intended applications.

• Choose a Trusted Brand: Invest in a reputable provider like CQX to ensure quality, reliability, and excellent customer service.

Pulse laser cleaning machines represent the pinnacle of cleaning technology, offering a sustainable, efficient, and precise solution to modern cleaning challenges. Their ability to adapt to diverse applications makes them an invaluable tool for industries ranging from manufacturing and restoration to electronics and healthcare.

With CQX leading the charge in innovation, businesses can trust that they are investing in reliable, high-performance equipment. Whether you’re removing rust, restoring historical artifacts, or cleaning sensitive components, CQX’s pulse laser cleaning machines deliver results you can count on.

Take the first step toward transforming your cleaning processes with CQX’s advanced pulse laser cleaning machines. Explore their solutions today and discover the future of precision cleaning.