Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

HW-SERIES 3KW

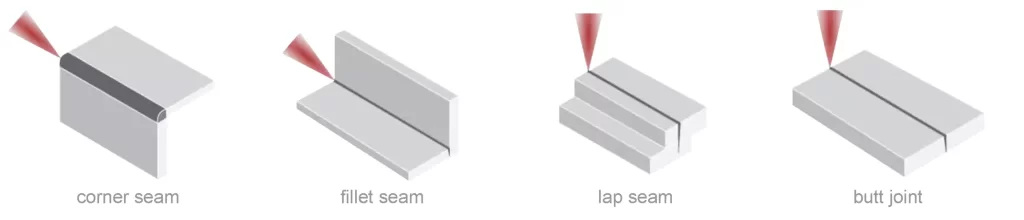

The internal design is dexterous, and the good interactive control system expands the tolerancerange of processing parts and the weld width, avoids the disadvantage of small light spots, andthe weld formation is better.

It is light in shape and comfortable to grip with the body engineering design method.The novice iseasy to control and operate.

The weld seam is beautiful, and the working speed is fast, There is no consumable, no weldingmark, no discoloration, and no need for later polishing.

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

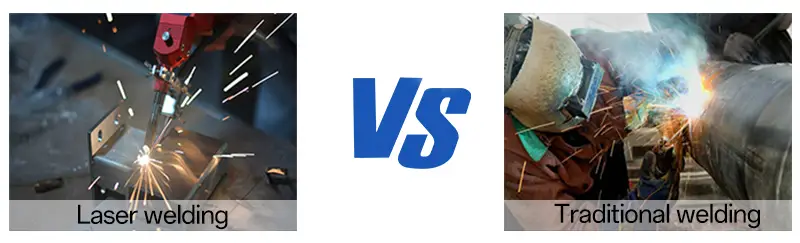

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

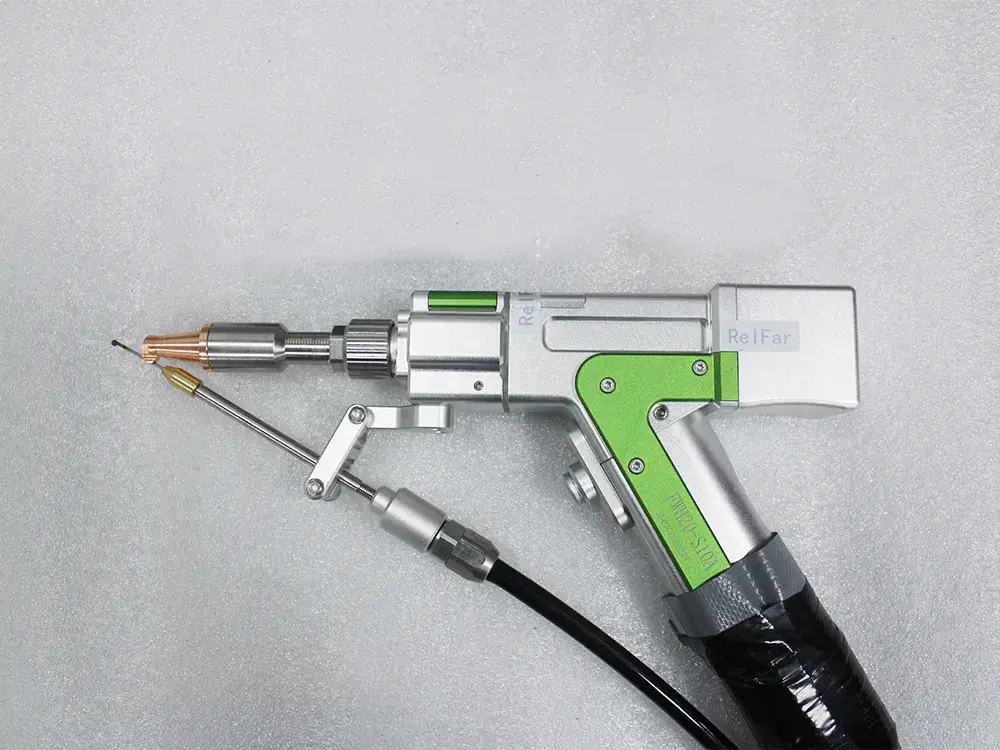

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

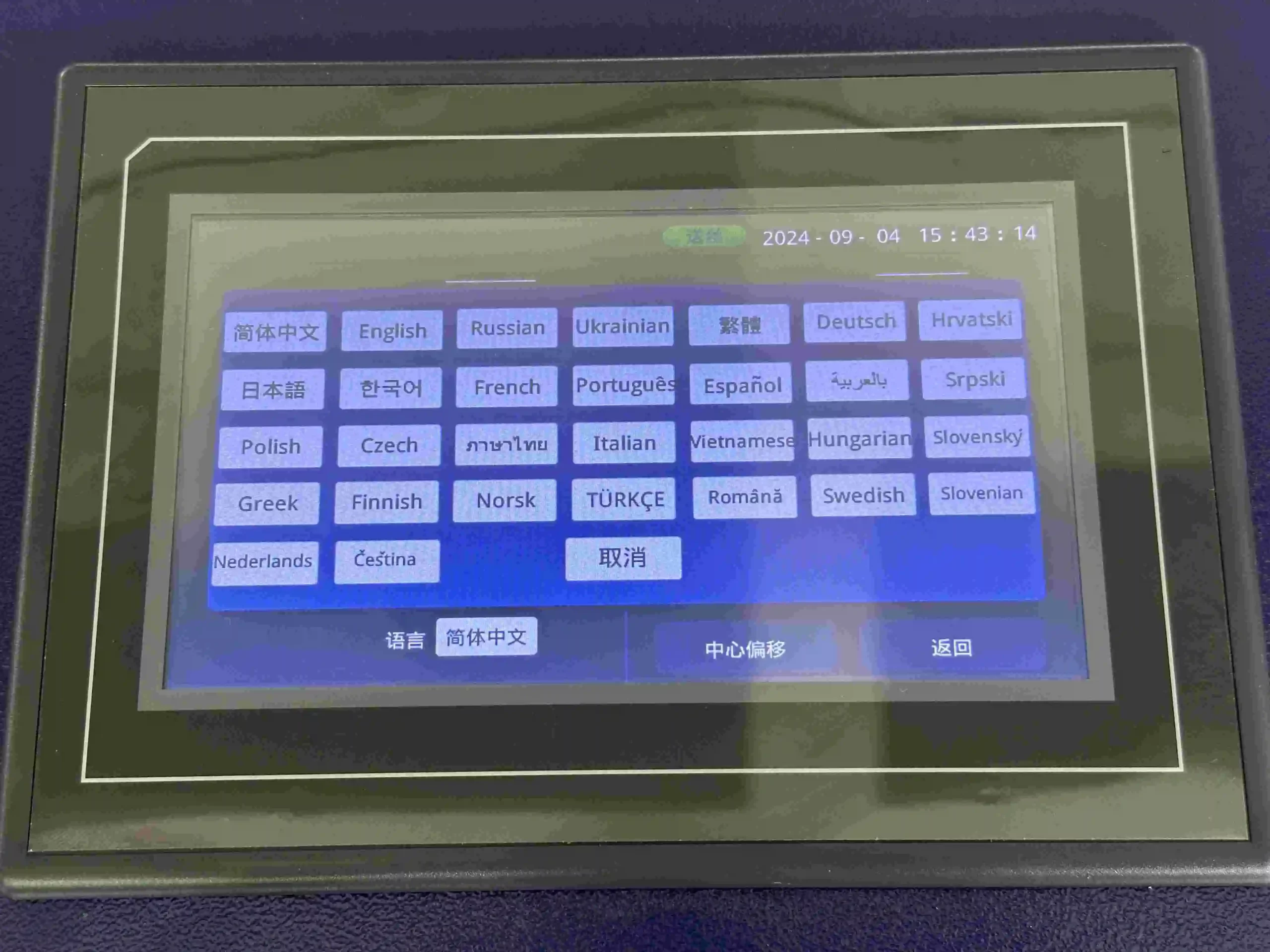

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

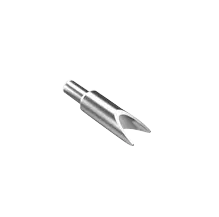

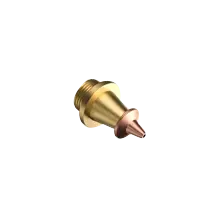

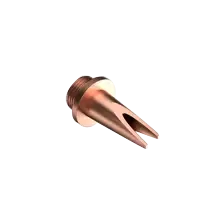

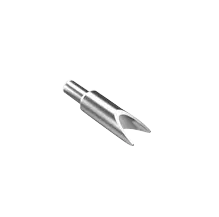

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| PERFORMANCETECHNICALPARAMETERS | ||||

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Wavelength | 1070nm | |||

| Mode of operation | Continuous | |||

| Cooling mode | WaterCooling | |||

| Voltage | 220V50/60Hz | |||

| Welding Thickness(Singleside) | 0.5-3mm | 0.5-4mm | 0.5-5mm | 0.5-8mm |

| Welding Speed | 0-120mm/s | |||

| Welding Gap | ≤0.5mm | |||

| Laser Lifetime | 100000h | |||

| Laser Source | MAX/Raycus/IPG/BWT | |||

| Laser Head&ControlSystem | Sup/Qilin/Relfar/Raytools | |||

| Fiber Cable Length | 10m,Customized20mmax | |||

| Working Required Temperature | 10-35°C | |||

| Machine Dimension | 990*600*1170mm | 1100*600*1180mm | ||

| Weight | 165kg | 173kg | 203kg | |

In a world where technology continuously evolves, the handheld laser welder stands at the forefront of innovation, offering unprecedented speed, versatility, and efficiency. Imagine a welding tool that is up to 4 times faster than traditional TIG welding, capable of handling a wide range of materials, and simple enough for anyone to master within minutes. This is not just a tool; it’s a revolution in welding.

Why Choose a Handheld Laser Welder?

Unmatched Speed and Efficiency

The handheld laser welder redefines welding speed. With adjustable laser welding power up to 3000W and preset user-defined modes, it delivers optimal material-thickness combinations effortlessly. The built-in wobble welding function extends the weld width by 5mm, making it perfect for parts with poor fit-up. This technology not only speeds up the welding process but also ensures high-quality, consistent results every time.

Versatility Across Materials

From steel to aluminum, copper, titanium, and nickel alloys, the handheld laser welder handles them all with ease. It is designed to weld materials up to 6.35 mm thick, making it an incredibly versatile tool for various applications. Whether you are working on automotive parts, aerospace components, or intricate metal art, this welder delivers flawless performance.

User-Friendly and Safe

The handheld laser welder is designed for ease of use. Optimized presets reduce the learning curve, enabling novice operators to achieve professional results with minimal training. The ergonomic design and lightweight build ensure comfort during extended use. Safety features, including a 2-step trigger, part contact sensor, emergency stop button, and safety interlock, provide a secure operating environment.

Consistent High-Quality Results

Consistency is key in welding, and the handheld laser welder guarantees high-quality, repeatable results. Its advanced technology minimizes distortion, deformation, undercut, and burn-through, ensuring that every weld is perfect. The low heat input preserves the material’s natural properties, creating strong, aesthetically pleasing joints.

Read More

Key Features of the Handheld Laser Welder Fast and Easy Setup

Setting up the handheld laser welder is a breeze. The clearly labeled rear connections, single-cable delivery of laser power, gas, and control connections, and intuitive touchscreen panel make the process quick and straightforward. Operators can switch seamlessly between standard laser welding, wire welding, and laser cleaning, enhancing productivity and flexibility.

Pre- and Post-Weld Cleaning

One of the standout features of the handheld laser welder is its pre- and post-weld cleaning capability. With cleaning it ensures greater welding quality and a pristine finish. This dual functionality streamlines the welding process, reducing the need for additional cleaning equipment.

Advanced Control System

The welding gun’s built-in display screen allows real-time monitoring and adjustment of welding parameters. Operators can customize and save presets for future use, ensuring consistency and efficiency. The system also features a key switch control, emergency stop button, and part contact electrical interlock for enhanced safety.

Comprehensive Safety Features

Safety is paramount with the handheld laser welder. It includes multiple safety measures such as grounding for fiber laser emission, low-voltage protection, temperature alarms, emergency stop functions, and part contact interlock. Operators must use protective equipment, including welding gloves, shields, and 1070 nm laser-safe glasses.

Robust Construction

The handheld laser welder is built to last. Its rugged design, combined with features like an oil-water separator to protect the focusing lens, ensures durability and longevity. The machine comes with a one-year warranty and a two-year warranty for the laser, providing peace of mind to operators.

Application and Performance Welding Capacity by Model

Control System and Wire Feeder

The control system of the handheld laser welder allows for precise adjustments to laser power, wobble frequency, and length. The wire feeder supports wire diameters of 0.8mm, 1.0mm, and 1.2mm 1.6 2.0mm, with speed adjustments through the touch panel. This ensures smooth and efficient welding, even for gaps larger than 0.2mm.

Common FAQs

What makes laser welding better than traditional welding?

Laser welding produces durable and aesthetically pleasing welds with significantly less material deformation. Its user-friendly interface requires less technical expertise, making it an efficient and accessible option for precise, high-quality welds.

How do I maintain a laser welding machine?

Regular cleaning, replacing consumables as per manufacturer recommendations, inspecting optics, and proper storage are key to maintaining your laser welding machine. This ensures longevity and optimal performance.

What safety measures are in place for the handheld laser welder?

Safety measures include grounding for fiber laser emission, low-voltage protection, temperature alarms, emergency stop buttons, and part contact electrical interlock. Operators must wear protective equipment, including welding gloves, shields, and 1070 nm laser-safe glasses.

What materials can the handheld laser welder handle?

The handheld laser welder can weld steel, aluminum, stainless steel, titanium, and various alloys. Its versatility makes it suitable for a wide range of applications.

How easy is it to learn and operate the handheld laser welder?

The handheld laser welder is incredibly easy to learn and operate. With optimized presets and an intuitive interface, even novice operators can achieve professional results within minutes.

Conclusion

The handheld laser welder is a game-changer in the welding industry. Its unmatched speed, versatility, ease of use, and consistent high-quality results make it the ideal choice for both novice and experienced welders. Whether you’re working on intricate metal art or heavy-duty industrial projects, this tool promises to deliver exceptional performance and efficiency. Embrace the future of welding with the handheld laser welder and experience the difference today.