Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

HW-SERIES 1-3KW

The internal design is dexterous, and the good interactive control system expands the tolerancerange of processing parts and the weld width, avoids the disadvantage of small light spots, andthe weld formation is better.

It is light in shape and comfortable to grip with the body engineering design method.The novice iseasy to control and operate.

The weld seam is beautiful, and the working speed is fast, There is no consumable, no weldingmark, no discoloration, and no need for later polishing.

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

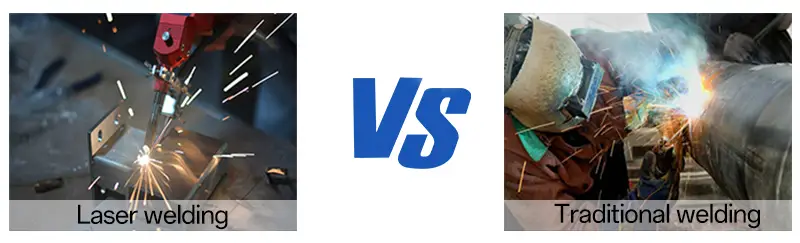

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

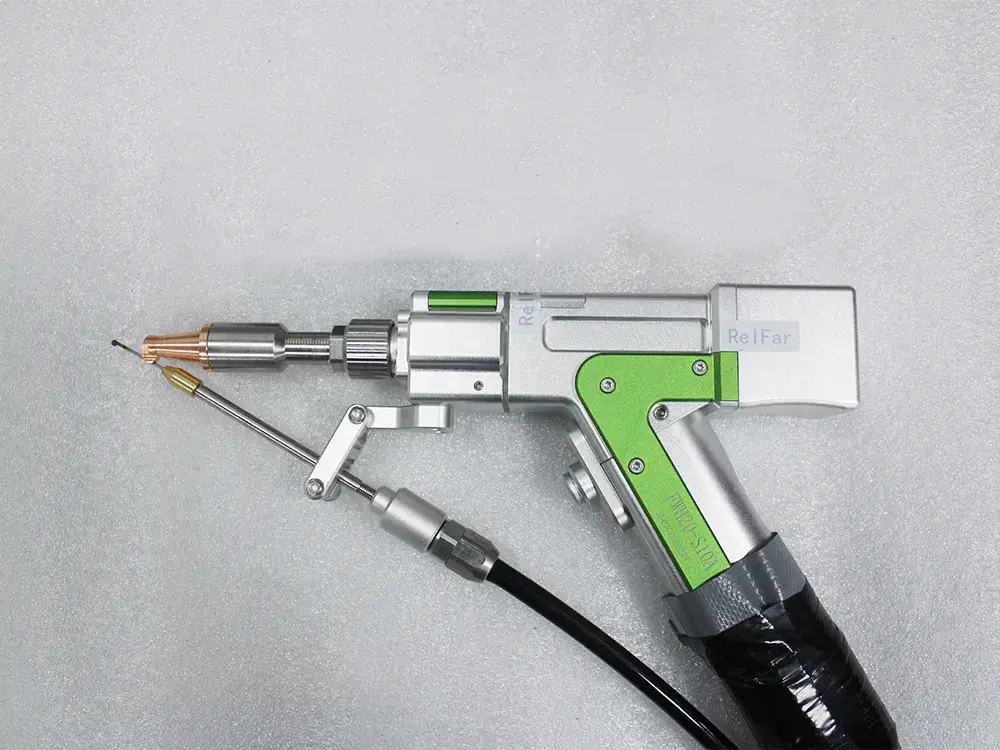

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

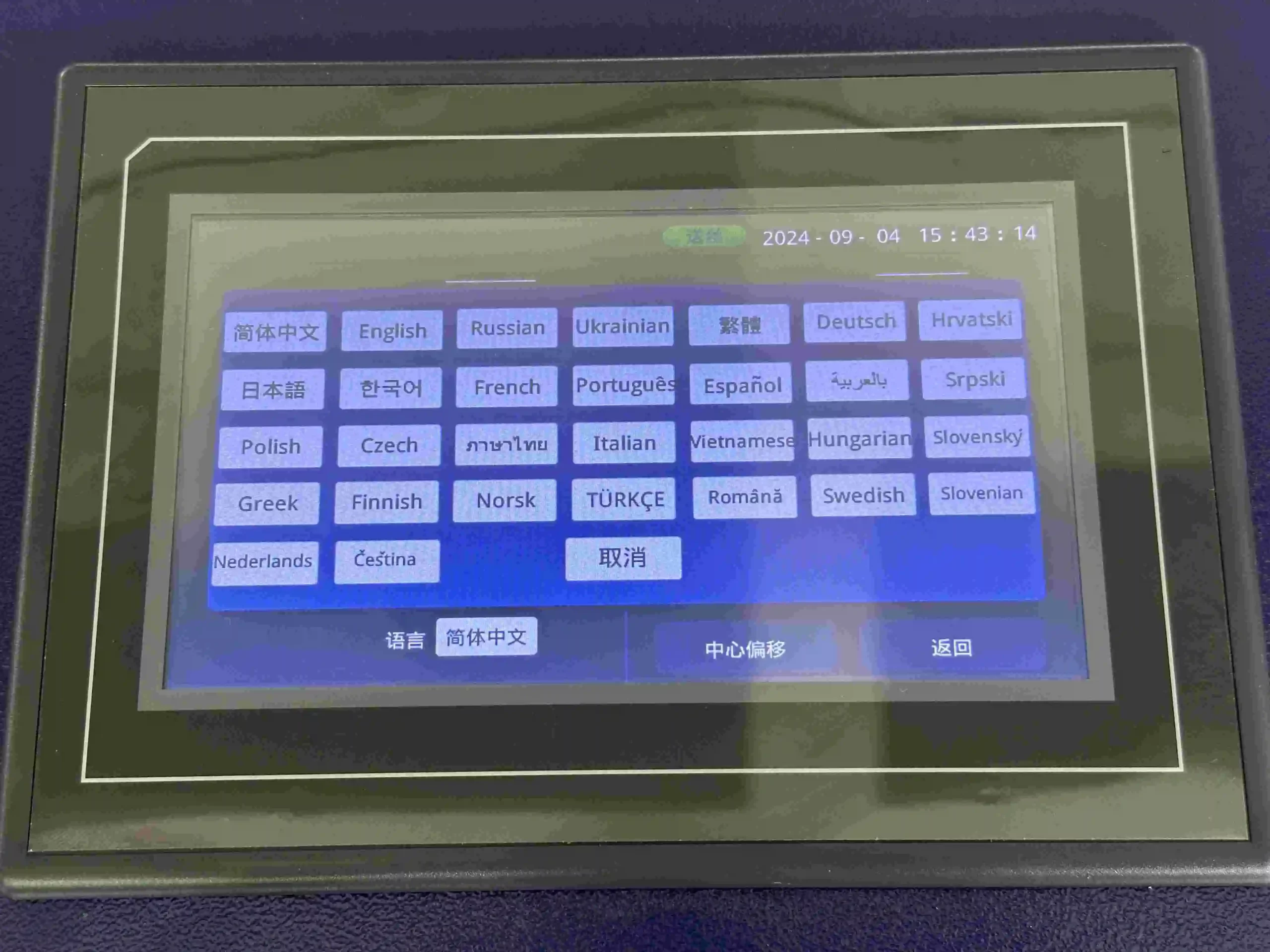

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

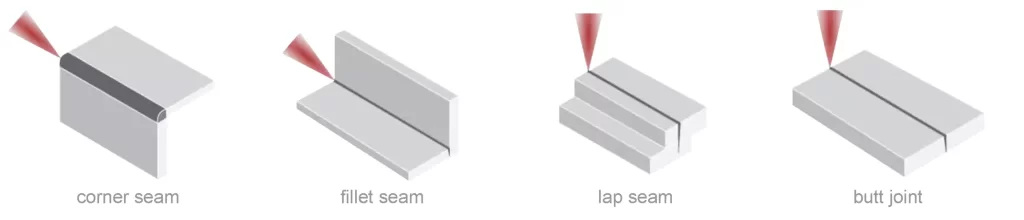

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| PERFORMANCETECHNICALPARAMETERS | ||||

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Wavelength | 1070nm | |||

| Mode of operation | Continuous | |||

| Cooling mode | WaterCooling | |||

| Voltage | 220V 50/60Hz | 380V 50/60Hz | ||

| Welding Thickness(Singleside) | 0.5-3mm | 0.5-4mm | 0.5-5mm | 0.5-8mm |

| Welding Speed | 0-120mm/s | |||

| Welding Gap | ≤0.5mm | |||

| Laser Lifetime | 100000h | |||

| Laser Source | MAX/Raycus/IPG/BWT | |||

| Laser Head&ControlSystem | Sup/Qilin/Relfar/Raytools | |||

| Fiber Cable Length | 10m,Customized20mmax | |||

| Working Required Temperature | 10-35°C | |||

| Machine Dimension | 920*650*1080mm | 1230*650*1080mm | ||

| Weight | 165kg | 190kg | ||

Handheld laser welding machines are revolutionizing the welding industry with their user-friendly interface, exceptional speed, and high-quality outcomes. These advanced tools provide a stark contrast to traditional MIG and TIG welding methods, which require years of training. With handheld laser welders, individuals can achieve professional results in as little as 5-30 minutes of instruction, making them an ideal choice for both beginners and seasoned welders.

Unprecedented Ease of Use

The standout feature of handheld laser welding machines is their simplicity. Traditional welding techniques demand extensive training and practice to master. In contrast, handheld laser welders can be learned quickly, often within 5-30 minutes. This rapid learning curve is due to the intuitive design of the machines, which are as easy to operate as a hot glue gun. This accessibility makes laser welding appealing for businesses aiming to reduce training time and costs, as well as for hobbyists and small-scale operators.

Precision with Minimal Heat Input

One of the critical advantages of handheld laser welding is the reduced heat input. Traditional welding generates substantial heat, which can cause part deformation and affect the integrity of the welded components. Handheld laser welders, however, use a concentrated laser beam that melts the metal almost instantly, resulting in minimal heat input. This precision minimizes the risk of part deformation, ensuring that the welded components retain their original shape and integrity. Additionally, the low heat input allows operators to work with minimal protective gear, such as lightweight gloves, as the parts do not get excessively hot.

Speed and Efficiency

Handheld laser welding machines are remarkably fast, significantly outpacing traditional welding methods. The machines can draw beads as quickly as the operator can move, boosting productivity. In many cases, handheld laser welders can be up to four times faster than TIG welding. This speed translates to higher output and reduced labor costs, making laser welding an attractive option for industries where time and efficiency are critical.

Versatility Across Various Materials

These machines are versatile, capable of welding a wide range of materials including aluminum, copper, steel, stainless steel, and titanium. They can handle various thicknesses, from thin sheets to thicker plates, and perform dissimilar metal welding. This versatility extends their application across different industries and projects. Handheld laser welders can also perform one-sided spot welding (laser riveting), replacing traditional methods like drilling holes and tapping screws, even when there’s no access to the backside of the part.

Read More

High-Quality Welds with Minimal Post-Processing

Handheld laser welders produce high-quality welds with minimal setup and post-processing. The welds are clean, with no discoloration or marks, eliminating the need for additional grinding or polishing. This quality is consistent across different welding positions, whether flat, horizontal, vertical, or overhead. The precision and cleanliness of laser welding reduce the need for extensive post-processing, saving time and effort.

Energy Efficiency

Compared to traditional welding equipment, handheld laser welding machines are more energy-efficient. They operate on 220V single-phase, 20 amps, making them suitable for various settings, including small workshops and large industrial operations. The lower power draw not only reduces energy costs but also makes these machines more environmentally friendly.

Minimal Protective Gear Required

The low flash and brightness of the laser beam mean that the operator needs minimal protective clothing. Unlike traditional welding, which requires heavy-duty protective gear, handheld laser welding allows for the use of lighter, more comfortable clothing, enhancing safety and comfort for the operator. This feature allows for longer working periods without fatigue, increasing overall productivity.

Advanced Control and Customization

Modern handheld laser welding machines come with advanced control systems that offer precise customization. The laser power, wobble frequency, and wobble length can be adjusted easily through intuitive controls. The wire feeder supports various wire diameters (0.8mm, 1.0mm, 1.2mm, 1.6mm), and the feed speed can be adjusted via a touch panel. This level of control ensures optimal performance for different welding tasks, enhancing the versatility and effectiveness of the machine.

Safety and Ergonomics

Safety is a crucial aspect of welding, and handheld laser welders are designed with this in mind. The new laser hand-held welding heads feature ergonomic designs, making them comfortable to grip and operate for extended periods. Additionally, these machines comply with international safety standards, featuring warning lights and other safety mechanisms to ensure safe operation. This emphasis on safety and ergonomics allows operators to work confidently and efficiently.

Applications and Industries

Handheld laser welding machines are used in a variety of industries due to their versatility and efficiency. Common applications include:

– Automotive Industry: Used for welding car body parts, frames, and other components, providing clean, strong welds without extensive post-processing. The speed and precision of laser welding are particularly beneficial in this industry, where production times are critical.

– Aerospace: In aerospace, precision and strength are paramount. Handheld laser welders are used for welding lightweight and high-strength materials, ensuring components meet stringent industry standards.

– Electronics: The electronics industry benefits from the precise and clean welds provided by laser welding, ideal for delicate connections and ensuring the integrity of electronic components.

– Medical Devices: For medical devices, cleanliness and precision are critical. Handheld laser welders are used for welding surgical instruments and other medical equipment, ensuring welds meet high standards.

– Jewelry: In the jewelry industry, the ability to create intricate designs and make delicate repairs is essential. Handheld laser welders allow for precise and clean welds, making them ideal for this application.

Disadvantages of Laser Welding

Despite its numerous advantages, handheld laser welding has some drawbacks that users should be aware of:

Lifespan and Maintenance

The lifespan of a laser welding machine is generally around 8 to 10 years, depending on usage and maintenance. Proper care and timely maintenance can extend the machine’s life, ensuring consistent performance and reliability. Regular maintenance tasks include cleaning the lenses, checking the alignment of the laser beam, and ensuring that the cooling system is functioning correctly. By following these maintenance practices, users can maximize the longevity and effectiveness of their laser welding equipment.

The Future of Handheld Laser Welding

The future of handheld laser welding looks promising, with ongoing advancements in technology expected to further enhance its capabilities and applications. Innovations in laser sources, control systems, and ergonomics will likely make these machines even more user-friendly and versatile. Additionally, as the technology becomes more widespread, the cost of entry-level machines is expected to decrease, making them accessible to a broader range of users.

Conclusion

Handheld laser welding machines represent a significant advancement in welding technology, offering unparalleled ease of use, speed, and high-quality results. Their numerous advantages make them an attractive option for various applications, from automotive and aerospace to electronics and jewelry. While there are some drawbacks, the benefits far outweigh the limitations, making them a valuable investment for businesses and individuals looking to enhance their welding capabilities. As the technology continues to evolve, handheld laser welding machines will undoubtedly play a crucial role in the future of welding, driving efficiency, precision, and quality across multiple industries.