Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

HC-SERIES 1-2KW

CW series handheld laser cleaning machine easy to install, control and realize automation. Stable continuous lightoutput, simple operation, high power cleaning efficiency;

The power to effortlessly strip rust and coatings off metal surfaces. With a range from 1000W to 2000W, it’s built for heavy-duty work yet precise enough for detailed tasks. It’s the reliable choice for quality and speed in any metal industrial setting.

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

Damage to the surface

Heavy pollution,

complicated waste disposal

High cost,

damage to the surface

Limited size of the

product being ceaned

| Comparison Items | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Rust Removal | Ultrasonic Cleaning |

|---|---|---|---|---|---|

| Working Principle | Laser | Chemical Cleaner | Sandpaper/Grinding Wheel | Dry Ice | Cleaning Agent |

| Contactless | Yes | No | No | Yes | No |

| No damage to workpiece | Yes | No | No | Yes | Yes |

| Cleanliness | High | Uneven | Uneven | Uneven | Small cleaning range |

| Cleaning Efficiency | High | Low | Low | Medium | Medium |

| Accuracy | High accuracy (Controllable) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Can't be specified (range cleaning) |

| Environmental Friendly | Yes | No | No | Yes | No |

| Manual Operation | Simple | Complex | Protective measuresrequired | Simple | Simple |

| Consumables | No | Yes | Yes | Yes | Yes |

Laser head brand (Sup/Qilin/Relfar)

1. High-threshold optical components for superior laser cleaning effects.

2. Laser gun has several safety locks for top performance security.

3. Whole-body water cooling design for enhanced and lasting stability.

4. Ergonomically designed for comfortable grip and easy handling.

5. Intelligent protection system with phone and PC monitoring,

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

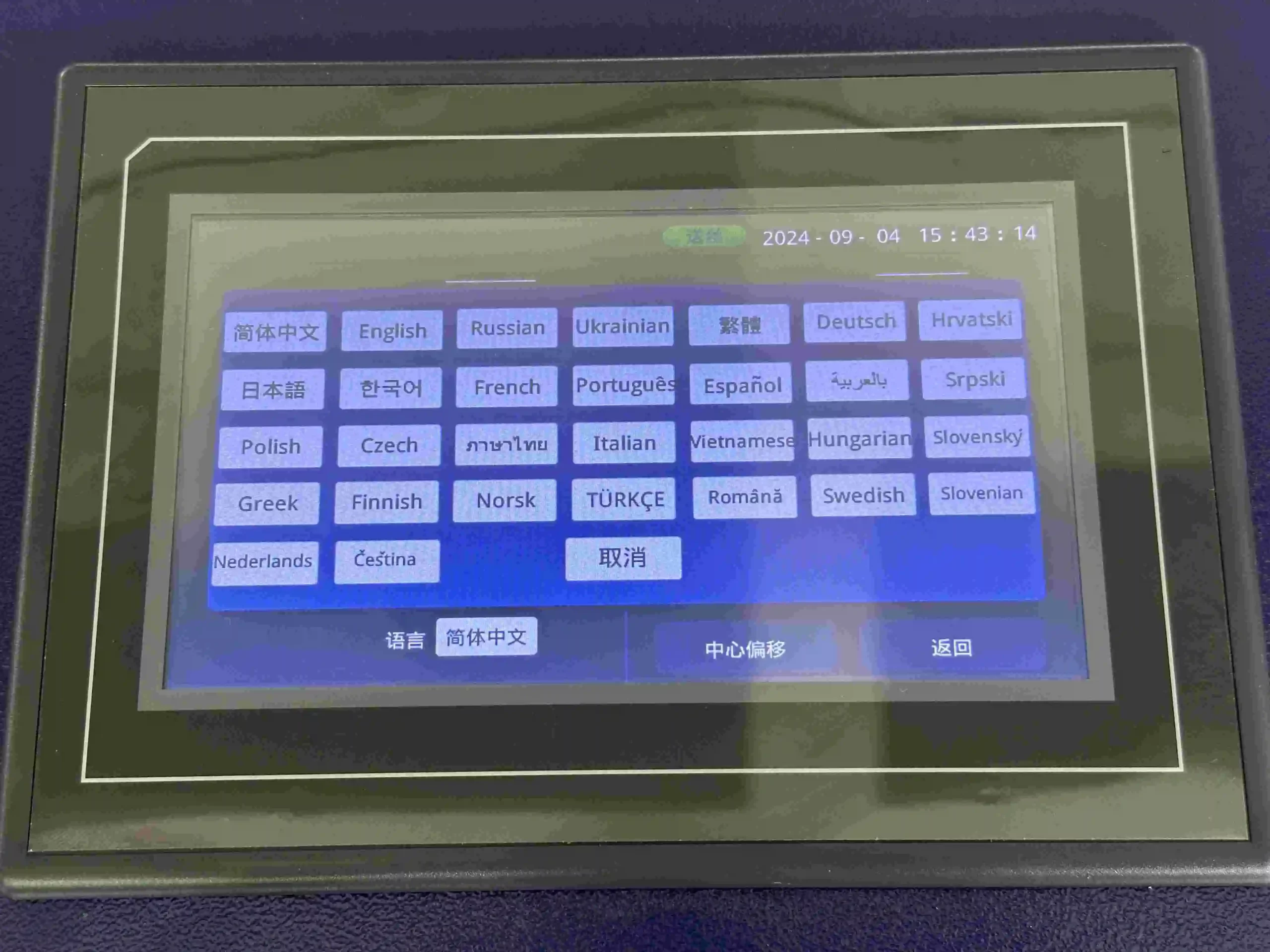

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| PERFORMANCETECHNICALPARAMETERS | |||

|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1070nm | ||

| Laser Type | CW Fiber Laser | ||

| Cooling mode | Water Cooling | ||

| Working Voltage | 220V±10%; 50/60Hz | ||

| Scan Width | 0-350mm, Can be customized | ||

| Power Adjustable Range | 5-100% | ||

| Scan Speed | 4000-15000mm/s | ||

| Laser Source | MAX/Raycus/IPG/BWT | ||

| Laser Head & Control System | Sup/Qilin/Relfar | ||

| Fiber Cable Length | 10m, Customized 20m max | ||

| Power Consumption | ≤10KW | ||

| Operating Temperature | 15-35℃ | ||

| Machine Size | 900*610*1030mm | ||

| Weight | 140kg | ||

Imagine a tool that combines the power of precision, the flexibility of portability, and the eco-friendliness of advanced laser technology. A tool that eliminates rust, paint, and residue without harming the underlying material. This is the innovation behind the handheld laser cleaning machine, a device that has reshaped how industries approach surface cleaning and restoration.

From restoring centuries-old artifacts to maintaining industrial machinery, this compact and powerful device has proven indispensable. But what makes it so revolutionary? How does it work, and why is it becoming the preferred choice for professionals across multiple sectors? In this in-depth guide, we’ll uncover the answers to these questions and explore why the handheld laser cleaning machine is a game-changer for modern cleaning needs.

In a world driven by technological innovation, cleaning methods must evolve to meet new challenges. The handheld laser cleaning machine stands out as an answer to the inefficiencies and limitations of traditional cleaning techniques. Here are some key reasons why this technology is gaining traction:

1.Chemical-Free and Environmentally Friendly

Traditional cleaning methods often rely on abrasive materials or harmful chemicals that pose risks to the environment and human health. Handheld laser cleaning machines eliminate the need for these, offering a completely chemical-free solution that generates no secondary waste.

2.Non-Destructive Precision Cleaning

Unlike sandblasting or grinding, which can damage delicate surfaces, laser cleaning targets only the unwanted layers of contaminants. This makes it perfect for preserving valuable materials and intricate designs.

3.Portability Without Compromising Power

As the name suggests, the handheld laser cleaning machine is designed for portability. Its lightweight construction and ergonomic design make it easy to use in various settings, from factories to outdoor sites.

4.Cost and Time Efficiency

Although the initial investment may be higher than traditional methods, the handheld laser cleaning machine saves money in the long run. It requires minimal maintenance, no consumables, and reduces labor costs due to its speed and efficiency.

5.Adaptability Across Applications

The versatility of handheld laser cleaning machines is unmatched. They are effective on a wide range of materials, including metals, glass, and stone, making them suitable for diverse industries.

Read More

The science behind the handheld laser cleaning machine is as innovative as its applications. Here’s a step-by-step breakdown of its working principle:

• Laser Beam Generation: The machine generates a high-intensity laser beam directed at the target surface.

• Energy Absorption: The contaminants absorb the laser energy, which causes them to vaporize or break away from the surface.

• Controlled Removal: By adjusting the machine’s settings, users can control the depth and intensity of cleaning, ensuring that only the unwanted material is removed.

• Residue-Free Cleaning: The vaporized contaminants are either blown away or collected using integrated systems, leaving a clean, residue-free surface.

This precision ensures that the base material remains intact, making laser cleaning a superior choice for sensitive and high-value surfaces.

The adaptability of handheld laser cleaning machines makes them a valuable asset across multiple sectors. Here are some of the most common applications:

1.Rust and Corrosion Removal

One of the primary uses of handheld laser cleaning machines is removing rust from metal surfaces. The process is quick, effective, and non-damaging to the underlying material.

2.Paint Stripping

Laser cleaning is ideal for removing paint layers without using harsh chemicals or abrasives, making it perfect for automotive and industrial refurbishing.

3.Cultural Artifact Preservation

Restorers use handheld laser cleaning machines to clean historical artifacts, sculptures, and monuments. The non-destructive nature of laser cleaning ensures the preservation of intricate details and delicate materials.

4.Industrial Maintenance

In manufacturing and processing plants, laser cleaning is used to remove grease, oil, and residues from machinery, ensuring optimal performance and longevity.

5.Welding Preparation and Post-Cleaning

Laser cleaning is used to prepare surfaces for welding by removing contaminants. It is also used after welding to clean weld seams, improving the quality and appearance of the final product.

6.Construction and Restoration

The handheld laser cleaning machine is frequently used to clean building facades, remove graffiti, and restore stone and concrete structures.

7.Precision Electronics Cleaning

In the electronics industry, laser cleaning is used to clean components with microscopic precision, ensuring functionality without causing damage.

The cost of a handheld laser cleaning machine depends on several factors. Understanding these can help you make an informed purchase:

1.Laser Power

Machines with higher wattage are more powerful and can handle tougher cleaning tasks. However, they also come at a higher price point.

2.Wavelength and Technology

The type of laser technology (e.g., fiber laser) and wavelength determine the machine’s effectiveness for specific applications and materials, influencing the cost.

3.Portability Features

Lightweight, ergonomic designs with advanced portability features are generally more expensive but offer greater convenience.

4.Customizable Settings

Machines with programmable features, adjustable laser intensities, and multi-mode cleaning capabilities cost more but provide superior flexibility.

5.Brand and Support

Established brands like CQX offer high-quality machines with robust warranties and customer support, ensuring long-term reliability and value.

6.Additional Accessories

Features like integrated cooling systems, dust collection units, and advanced safety mechanisms can add to the overall cost.

CQX has established itself as a trusted name in laser technology, offering innovative and reliable solutions. Here’s why CQX stands out:

• State-of-the-Art Technology: CQX incorporates the latest advancements in laser cleaning technology to deliver unparalleled performance.

• Customizable Solutions: Their handheld laser cleaning machines are designed to meet the specific needs of diverse industries.

• Comprehensive Support: CQX provides end-to-end support, from machine installation to user training and ongoing maintenance.

• Cost-Effective Pricing: By balancing quality and affordability, CQX makes cutting-edge laser cleaning technology accessible to businesses of all sizes.

Selecting the right machine for your needs requires careful evaluation. Here are some tips to guide your decision:

• Identify Your Cleaning Needs: Consider the type of material, level of contamination, and scale of your cleaning tasks.

• Evaluate Power and Features: Choose a machine with the appropriate power output and features for your specific applications.

• Test the Machine: Whenever possible, request a demonstration to assess its performance and ease of use.

• Consider Long-Term Costs: Factor in maintenance, operational costs, and potential savings when evaluating the price.

• Opt for a Trusted Brand: Invest in a reliable provider like CQX to ensure long-term value and support.

The handheld laser cleaning machine represents a significant leap forward in cleaning technology. Its combination of portability, efficiency, and precision makes it an indispensable tool for industries worldwide.

As businesses increasingly prioritize sustainability and efficiency, the demand for eco-friendly solutions like laser cleaning will continue to grow. With CQX at the forefront of this innovation, companies can trust that they are investing in reliable, cutting-edge technology. Whether you’re in manufacturing, restoration, or maintenance, the handheld laser cleaning machine is a transformative solution for modern cleaning challenges.