Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

CQX-M 1-3kw

3-in-1 laser welding machine features unique welding heads, touchscreens, and buttons, ensuring seamless user operations. Incorporating welding, cleaning, and cutting functions into one machine, our 3 in 1 laser welding machine offers versatility, flexibility, and convenience.

The powerful and flexible 3 in 1 laser welding machine is suitable for a wide range of metals such as stainless steel, aluminium, copper, and titanium, which can meet various welding needs.

Because of its high precision and quality welding, it is also used in precision component manufacturing.

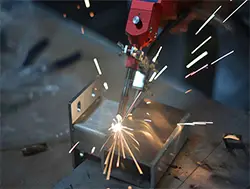

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

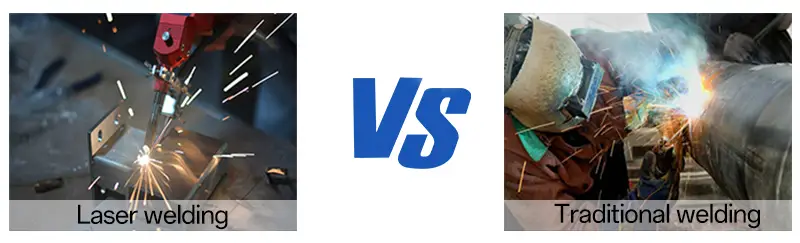

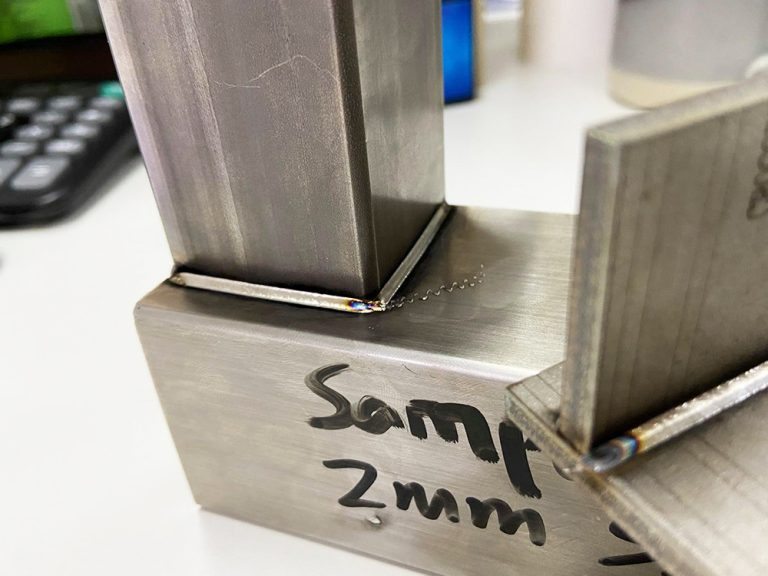

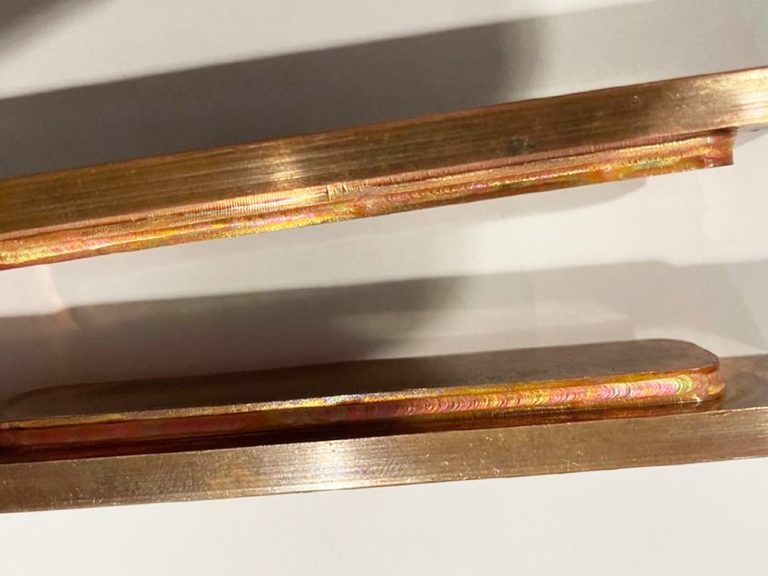

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

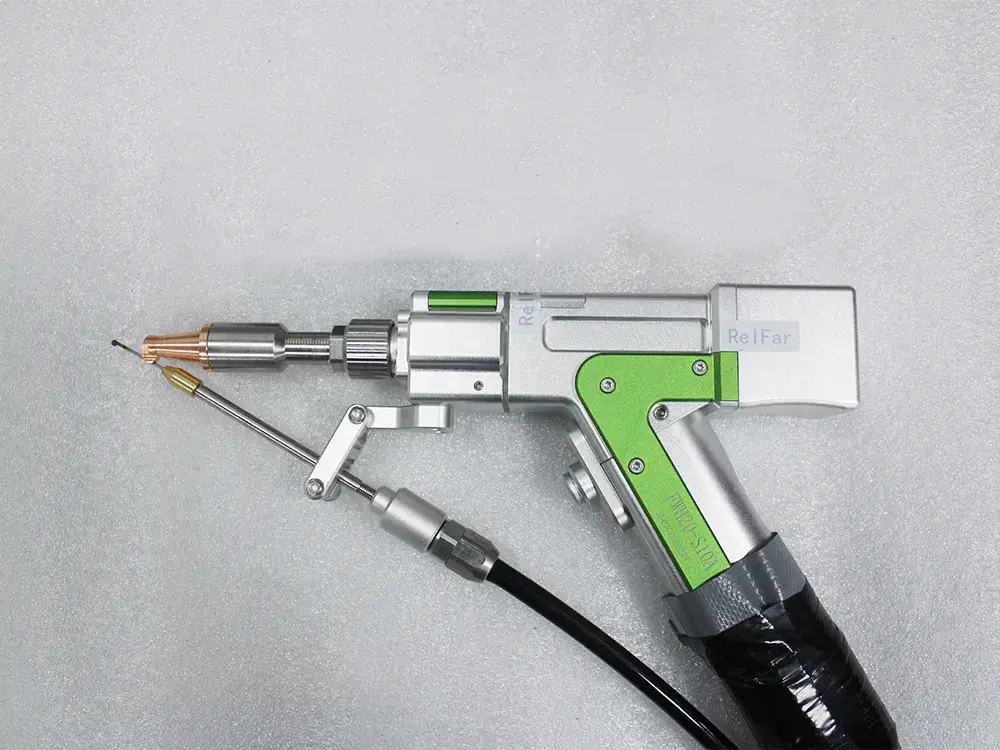

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

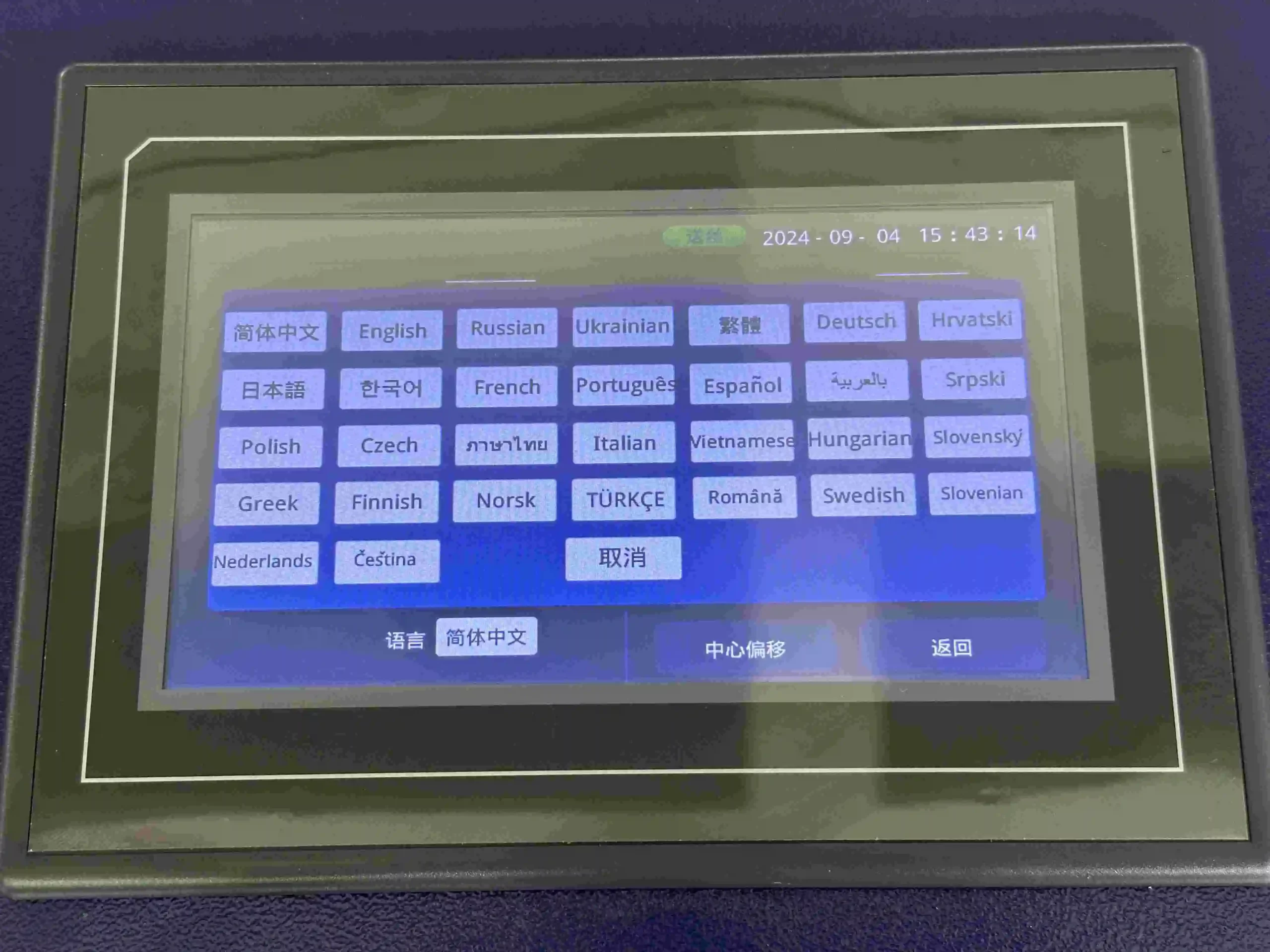

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

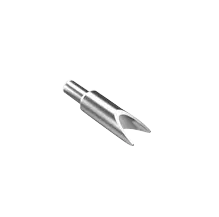

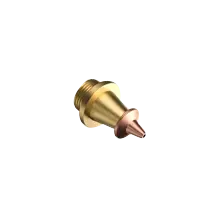

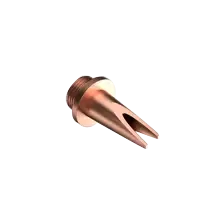

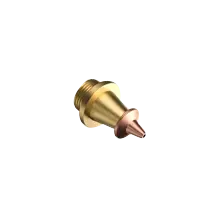

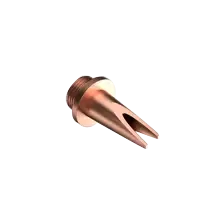

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

The 1000W- 3000W 3-in-1 laser welding machine features cleaning, cutting, and welding modes. In the metal processing and manufacturing sector, it efficiently welds and cuts various types of metals,

including stainless steel, aluminum, and copper, for the production of a wide range of metal components and products.

| -PERFORMANCE TECHNICAL PARAMETERS- | ||||

|---|---|---|---|---|

| Power | 1000W | 1500W | 2000W | 3000W |

| Laser Wavelength | 1070nm | |||

| Laser Type | Continuous | |||

| Cooling mode | Water Cooling | |||

| Voltage | 220V, 50/60Hz | 380V, 50/60Hz | ||

| Laser Lifetime | 100000h | |||

| Laser Source | MAX/Raycus/IPG/BWT | |||

| Laser Head & Control System | Sup/Qilin/Relfar/Raytools | |||

| Fiber Cable Length | 10m, Customized 20m max | |||

| Working Required Temperature | 10-35℃ | |||

| Machine Dimension | 920*650*1080mm | 1230*650*1080mm | ||

| Weight | 160kg | 190kg | ||

In the realm of modern manufacturing and fabrication, few innovations have made as significant an impact as the 3 in 1 laser welding machine. This revolutionary piece of equipment brings together three essential functions—welding, cleaning, and cutting—into a single, highly efficient unit. By harnessing the power of laser technology, it redefines productivity, precision, and convenience. Whether you’re working in aerospace, automotive, or metal fabrication, this machine unlocks possibilities that traditional tools simply can’t match.

1. A Multitasking Marvel

The 3 in 1 laser welding machine is the epitome of versatility, offering three critical operations in one:

1.Laser Welding: Perfect for joining metal components with unmatched accuracy and strength.

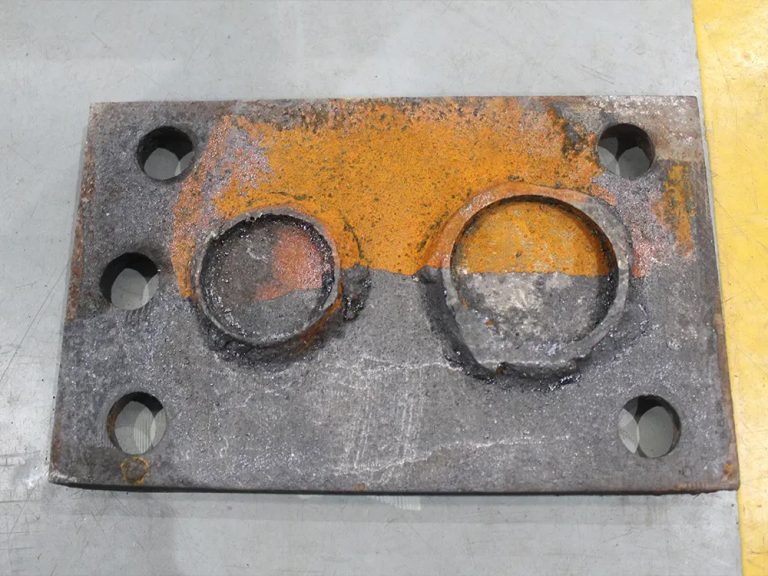

2.Laser Cleaning: Efficiently removes rust, paint, grease, and impurities from surfaces.

3.Laser Cutting: Creates precise cuts across various metals and materials, ensuring smooth edges.

This three-in-one capability not only saves space but also reduces the need for multiple tools, making it the perfect solution for modern workshops striving for efficiency and precision.

2. Benefits That Redefine Fabrication

• Enhanced Productivity

The integrated functionality means operators can switch seamlessly between welding, cleaning, and cutting without needing to change machines, drastically reducing setup and transition times.

• Unmatched Precision

Laser technology ensures that every cut, weld, or cleaned surface is free of imperfections, giving businesses a competitive edge by minimizing rework.

• Cost Reduction

With a single investment in a 3 in 1 laser welding machine, companies save on capital expenditure, maintenance, and workspace requirements.

Read More

The science behind laser welding, cleaning, and cutting is rooted in the concentration of a powerful light beam that interacts with metal at a microscopic level.

The benefits of this technology over traditional methods include:

• Minimal Heat Distortion: The narrow heat-affected zone (HAZ) ensures the base material remains unchanged outside the weld.

• Superior Weld Strength: The deep penetration of the laser weld creates a robust bond.

• Speed and Consistency: The process is significantly faster while maintaining accuracy.

1. Industrial Manufacturing

Industries such as automotive and aerospace rely on the laser welding machine for its ability to handle high-strength materials and complex geometries.

2. Metalworking and Custom Fabrication

Small businesses and fabrication shops benefit from the precision and adaptability of this machine, enabling them to produce customized, high-quality pieces.

3. Jewelry and Electronics

The laser’s precision is crucial for intricate work such as repairing fine jewelry, assembling small components, and micro-welding tasks in electronic devices.

4. Medical Devices

Laser welding plays a pivotal role in creating biocompatible, corrosion-resistant surgical instruments and implants.

5. DIY and Creative Projects

The increasing accessibility of portable 3 in 1 laser welding machines has led to their adoption by hobbyists and DIY enthusiasts for home improvement and artistic projects.

The 3 in 1 laser welding machine is designed to work with a wide range of materials, such as:

• Stainless steel

• Carbon steel

• Aluminum alloys

• Titanium

• Copper and brass

This broad compatibility makes it an indispensable tool across industries.

Performance Metrics

| Parameter | 3 in 1 Laser Welding Machine | Traditional Arc Welding |

|---|---|---|

| Heat Distortion | Minimal | High |

| Weld Strength | Superior | Moderate |

| Cutting Precision | High | Moderate |

| Cleaning Efficiency | Fast and non-abrasive | Manual and time-consuming |

1. Power Requirements

Different tasks require different power outputs. A higher wattage laser is essential for heavy-duty industrial applications, while lower wattages are sufficient for thin metals and precision work.

2. User Interface and Software

Choose a machine with an intuitive user interface, adjustable settings, and customizable presets for faster workflow optimization.

3. Safety Features

Safety should always be a priority. Look for machines with:

• Automatic shutoff mechanisms

• Overheat protection

• Protective shields and goggles for laser exposure

1. Operator Training

To fully utilize the machine’s potential, ensure operators are trained in:

• Laser calibration

• Material-specific settings

• Switching between functions seamlessly

2. Regular Maintenance

Extend the lifespan of your 3 in 1 laser welding machine by following these maintenance tips:

• Clean the optics regularly to prevent dust buildup.

• Replace worn-out nozzles and filters as needed.

• Perform software updates to keep the machine operating at peak performance.

3. Workspace Setup

Ensure your workspace is optimized for safety and efficiency by:

• Maintaining proper ventilation to manage fumes.

• Keeping the machine in a stable, clean environment to avoid external vibrations or interference.

1. AI and Automation

Modern laser machines are increasingly incorporating AI to:

• Detect defects during the welding process.

• Adjust settings automatically for optimal results.

2. Compact, Portable Models

Manufacturers are developing more compact and portable 3 in 1 laser welding machines, making it easier for fieldwork professionals to conduct on-site repairs.

3. Sustainability Focus

With energy-efficient designs, these machines consume less power while delivering exceptional results, aligning with global sustainability goals.

“They are too complicated to use.”

• In reality, most machines come with user-friendly interfaces that make operation simple, even for beginners.

“They can’t handle thick metals.”

• With the right power settings, these machines can cut and weld thick, industrial-grade metals effortlessly.

Many businesses have transformed their operations by adopting 3 in 1 laser welding machines. From small metalworking shops reducing overhead costs to large-scale manufacturers increasing output efficiency, the benefits are tangible.

By embracing the cutting-edge technology of the 3 in 1 laser welding machine, you position yourself at the forefront of innovation. Whether for precision tasks or heavy-duty fabrication, this all-in-one tool is the key to achieving unparalleled results. Revolutionize your workflow and experience the future of fabrication today.