Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

CQX-AW-X

Small and portable design: Compact size improves the convenience of transportation, Indooroutdoor&welding scene,Free switching

Air cooling system: Ensures the stability of the handheld laser welding machine.

Key parts: modular design Quick maintenance.No water tank Maintenance-free

Multi-function control function: The control button starts, stops and adjusts various equipment functions, providing comprehensive equipment control.

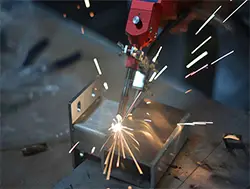

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

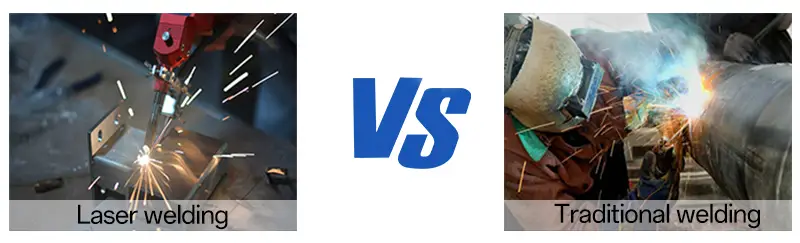

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

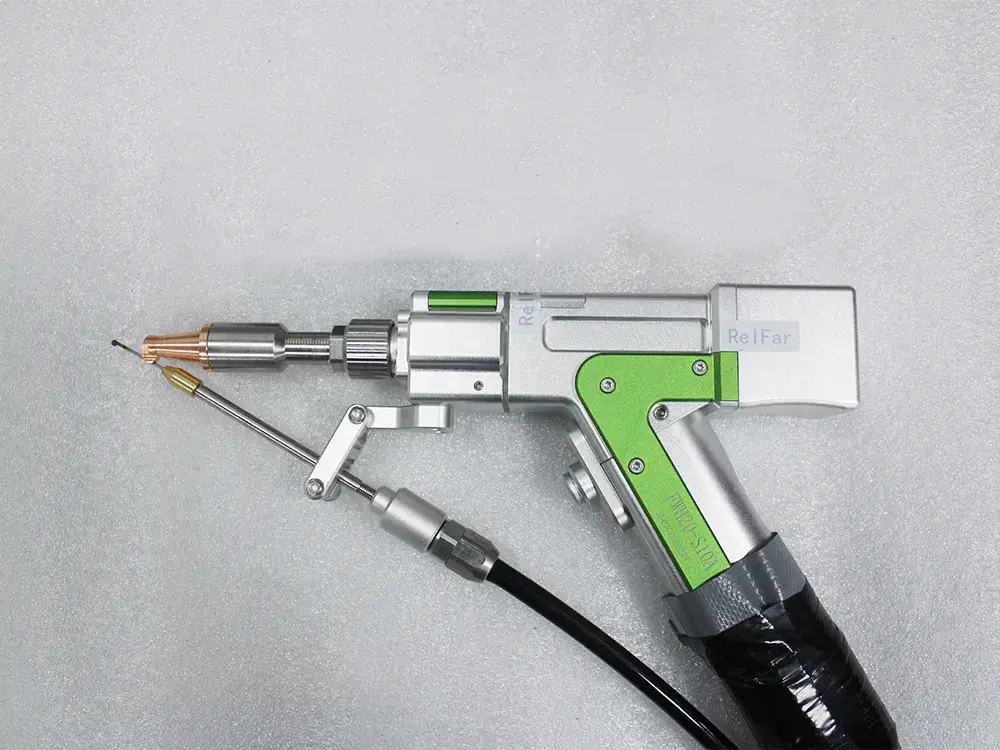

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

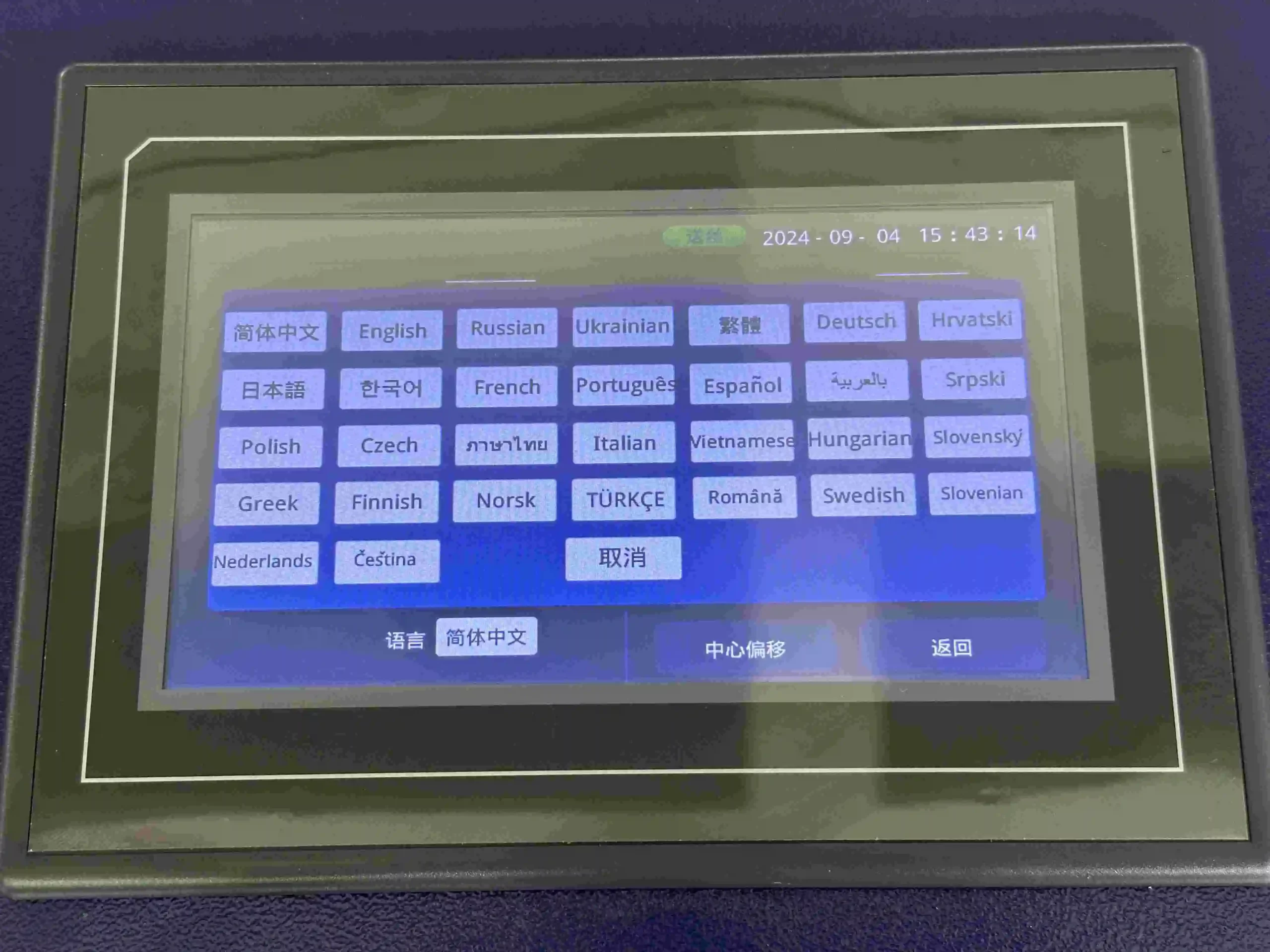

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

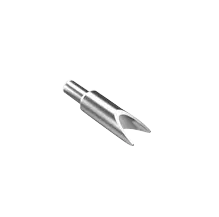

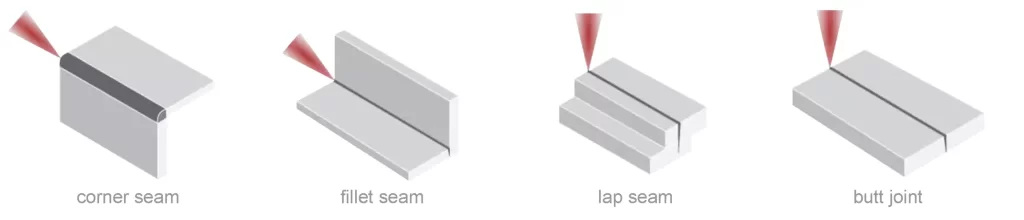

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

Applicable to various metals and alloys such as stainless steel, carbon steel, copper, aluminum, chromium, nickel, titanium, etc.

| PERFORMANCETECHNICALPARAMETERS | |||

|---|---|---|---|

| Model | CQX-AW-X3 | CQX-AW-X4 | CQX-AW-X5 |

| Pump Power | 1100W | 1440W | 2200W |

| Input Power | 220V single phase, 16A | 220V single phase, 24A | |

| Wobble frequency & width | 120Hz, 5mm | ||

| Welding Thickness(Single Side/Double side) | |||

| Stainless Steel | 3mm/6mm | 4mm/8mm | 5mm/10mm |

| Galvanized sheet | 3mm/6mm | 4mm/8mm | 5mm/10mm |

| Carbon steel | 3mm/6mm | 4mm/8mm | 5mm/10mm |

| Aluminum | 2mm/4mm | 3mm/6mm | 4mm/8mm |

| Brass | 1.5mm/3mm | 2mm/4mm | 3mm/6mm |

| Copper | 1mm/2mm | 1.5mm/3mm | 2mm/4mm |

| Size | 415*550*225mm | 620*525*255mm | |

| Weight | 28kg | 29kg | 41kg |

Imagine a world where high precision meets affordability. A world where even the smallest, most intricate welding tasks can be tackled with ease, efficiency, and reliability. That’s exactly what the small laser welding machine price from CQX Laser brings to the table—unparalleled value and groundbreaking technology that transforms the way you approach welding.

Laser welding technology has revolutionized industries across the globe, from aerospace to jewelry crafting, and CQX Laser’s small laser welding machines are designed to bridge the gap between high-tech innovation and practical affordability. But what makes these machines stand out? Let’s dive deep into their benefits, features, and how they cater to a variety of industries while maintaining an accessible price point.

1.Compact Design, Big Impact

Small laser welding machines are compact yet incredibly powerful. Their lightweight design and small footprint make them ideal for businesses with limited space. Despite their size, they deliver unmatched precision and durability.

2.Cost-Effective Solutions

The demand for cost-efficient welding solutions has been rising, and small laser welding machines meet this need perfectly. The small laser welding machine price ensures that even small businesses and independent artisans can invest in top-notch technology without breaking the bank.

3.Versatility in Applications

From automotive manufacturing to medical devices and electronics, small laser welding machines excel in a range of industries. Their ability to weld diverse materials like stainless steel, aluminum, titanium, and even precious metals makes them a go-to solution for both industrial and creative applications.

Read More

Understanding the Factors Behind Small Laser Welding Machine Prices

When exploring the small laser welding machine price, it’s essential to understand the factors that contribute to their cost. Here’s a breakdown:

• Laser Source Quality: High-quality laser sources ensure precision and longevity, which directly impacts the price. Machines with advanced fiber laser sources tend to be more expensive but offer superior performance.

• Welding Speed: Faster machines with higher processing speeds may come at a premium, but they also boost productivity and efficiency.

• Customization Options: Machines with adjustable power settings and programmable features often have higher upfront costs but provide long-term value through versatility.

• Brand Reputation: Trusted brands like CQX Laser offer reliable machines with robust customer support, adding value to the price tag.

How CQX Laser Balances Quality and Price

At CQX Laser, the focus isn’t just on providing affordable solutions—it’s about delivering machines that strike the perfect balance between cost and quality. By leveraging cutting-edge technology and innovative engineering, CQX Laser ensures that every machine offers:

• High precision with minimal thermal distortion

• Longevity and low maintenance requirements

• User-friendly interfaces for seamless operation

• Energy efficiency to lower operational costs

1.Precision and Accuracy

With pinpoint accuracy, these machines excel in welding even the tiniest details. This makes them ideal for industries requiring extreme precision, such as watchmaking or medical implants.

2.Ease of Use

Forget complicated setups. CQX Laser’s machines come with intuitive interfaces that allow both beginners and seasoned professionals to achieve optimal results.

3.Jewelry and Accessories

The small laser welding machine is a jeweler’s best friend. It allows for seamless repairs and intricate designs, making it indispensable for creating and maintaining high-end jewelry pieces.

4.Automotive and Aerospace

In industries where safety and durability are paramount, small laser welding machines deliver the precision required for critical components.

5.Medical and Dental Tools

From surgical instruments to dental appliances, these machines ensure that even the smallest tools meet stringent quality standards.

6.Electronics

Small components like circuit boards require precision welding, which these machines handle with ease.

1.Increased Productivity

Small laser welding machines streamline the welding process, reducing time and effort while improving output quality.

2.Reduced Costs Over Time

While the initial investment might seem significant, these machines pay for themselves through lower maintenance costs, minimal material waste, and energy efficiency.

3.Versatility Across Projects

Whether you’re repairing jewelry, creating prototypes, or working on precision-engineered components, these machines adapt to your needs effortlessly.

1.Jewelry and Accessories

The small laser welding machine is a jeweler’s best friend. It allows for seamless repairs and intricate designs, making it indispensable for creating and maintaining high-end jewelry pieces.

2.Automotive and Aerospace

In industries where safety and durability are paramount, small laser welding machines deliver the precision required for critical components.

3.Medical and Dental Tools

From surgical instruments to dental appliances, these machines ensure that even the smallest tools meet stringent quality standards.

4.Electronics

Small components like circuit boards require precision welding, which these machines handle with ease.

1.Welding Capabilities

Ensure the machine can handle the materials and thicknesses you commonly work with.

2.Ease of Maintenance

Choose a machine with accessible parts and minimal maintenance requirements.

3.Warranty and Support

Opt for brands like CQX Laser that offer robust warranties and customer support for peace of mind.

4.Customization Options

Machines with programmable features allow you to adapt to various projects with ease.

With years of expertise and a commitment to innovation, CQX Laser has become a trusted name in the laser welding industry. Their machines are designed to meet the diverse needs of users while maintaining competitive pricing. Whether you’re a small business or a large enterprise, CQX Laser offers solutions that help you achieve your goals efficiently and affordably.

The small laser welding machine price offered by CQX Laser is more than just a cost—it’s an investment in precision, efficiency, and innovation. As industries continue to evolve, these compact yet powerful machines stand out as a game-changing tool for businesses of all sizes.

Whether you’re looking to enhance your production line, explore creative possibilities, or simply improve the quality of your work, CQX Laser’s small laser welding machines are the perfect solution. Explore the possibilities today and see how affordable precision welding can transform your business!