Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

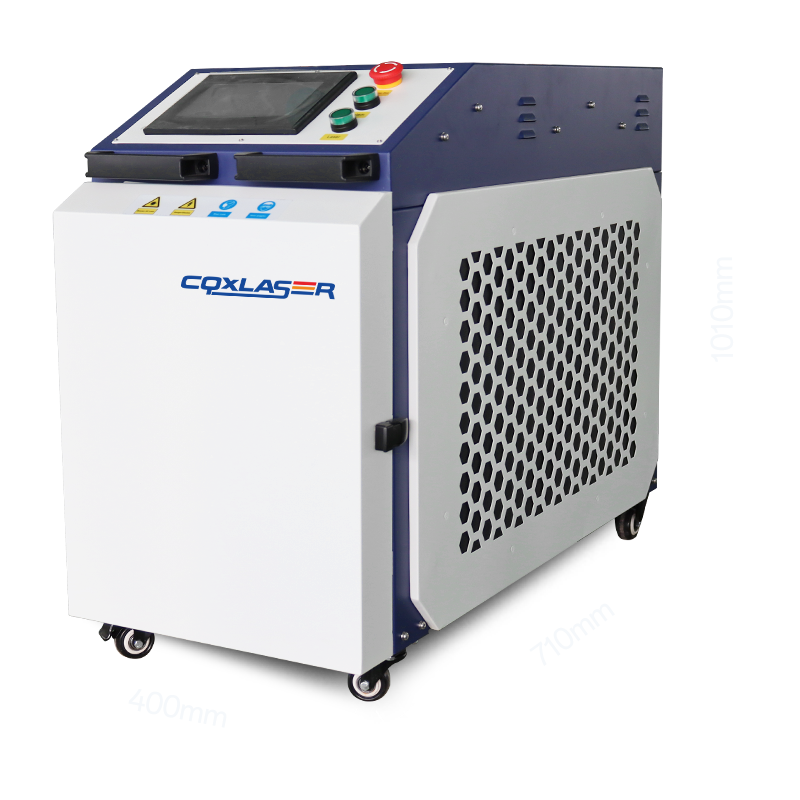

CQX-M

3-in-1 laser welding machine features unique welding heads, touchscreens, and buttons, ensuring seamless user operations. Incorporating welding, cleaning, and cutting functions into one machine, our 3 in 1 laser welding machine offers versatility, flexibility, and convenience.

The powerful and flexible 3 in 1 laser welding machine is suitable for a wide range of metals such as stainless steel, aluminium, copper, and titanium, which can meet various welding needs.

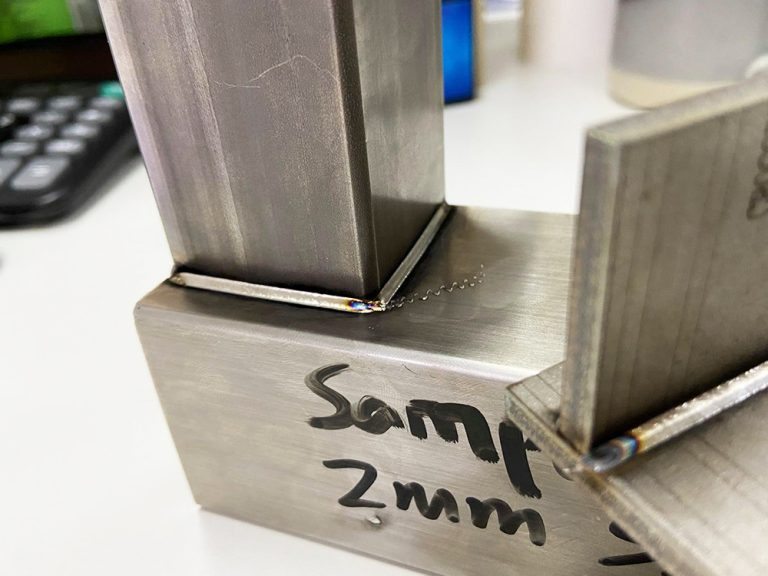

Because of its high precision and quality welding, it is also used in precision component manufacturing.

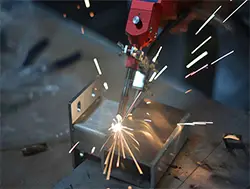

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

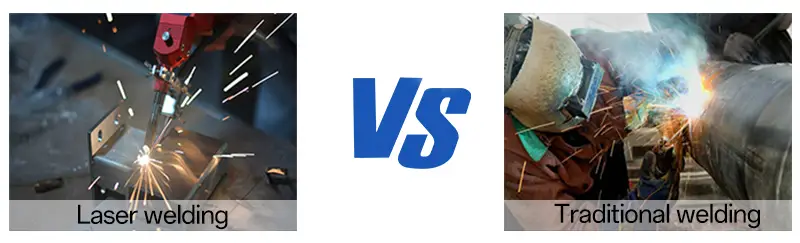

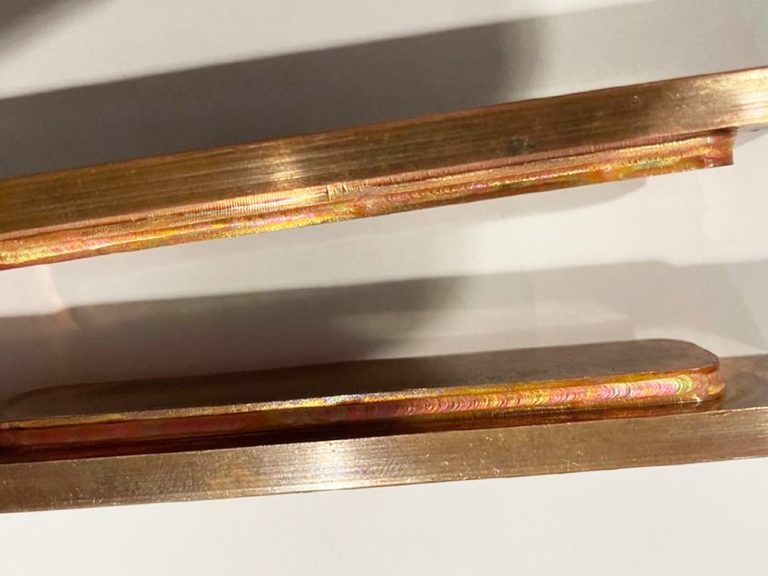

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

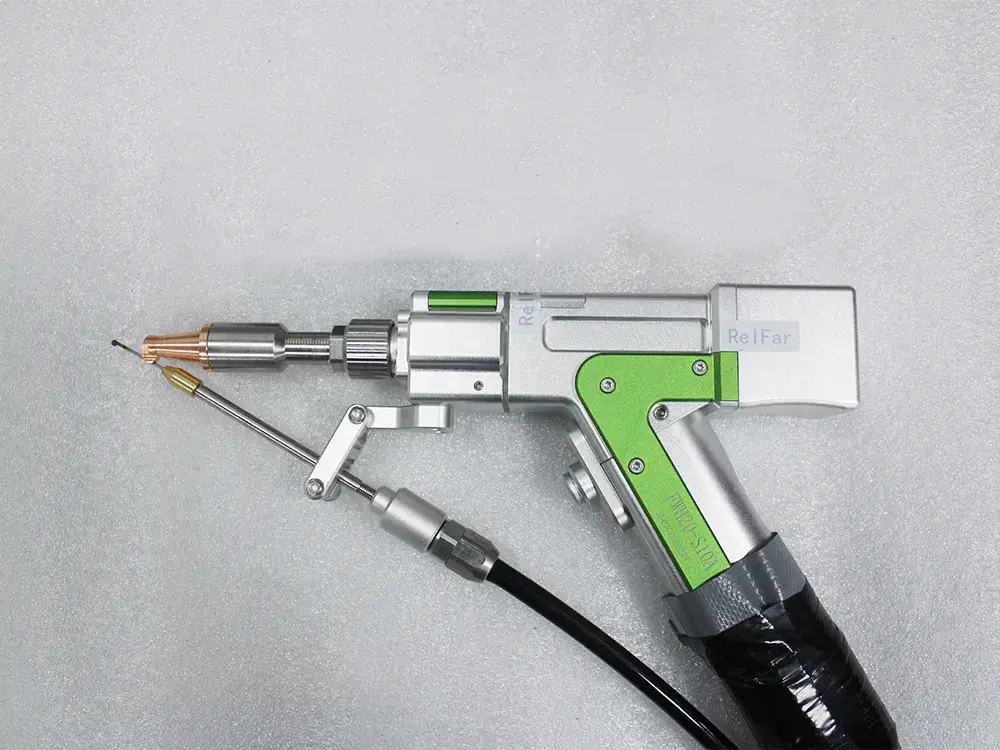

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

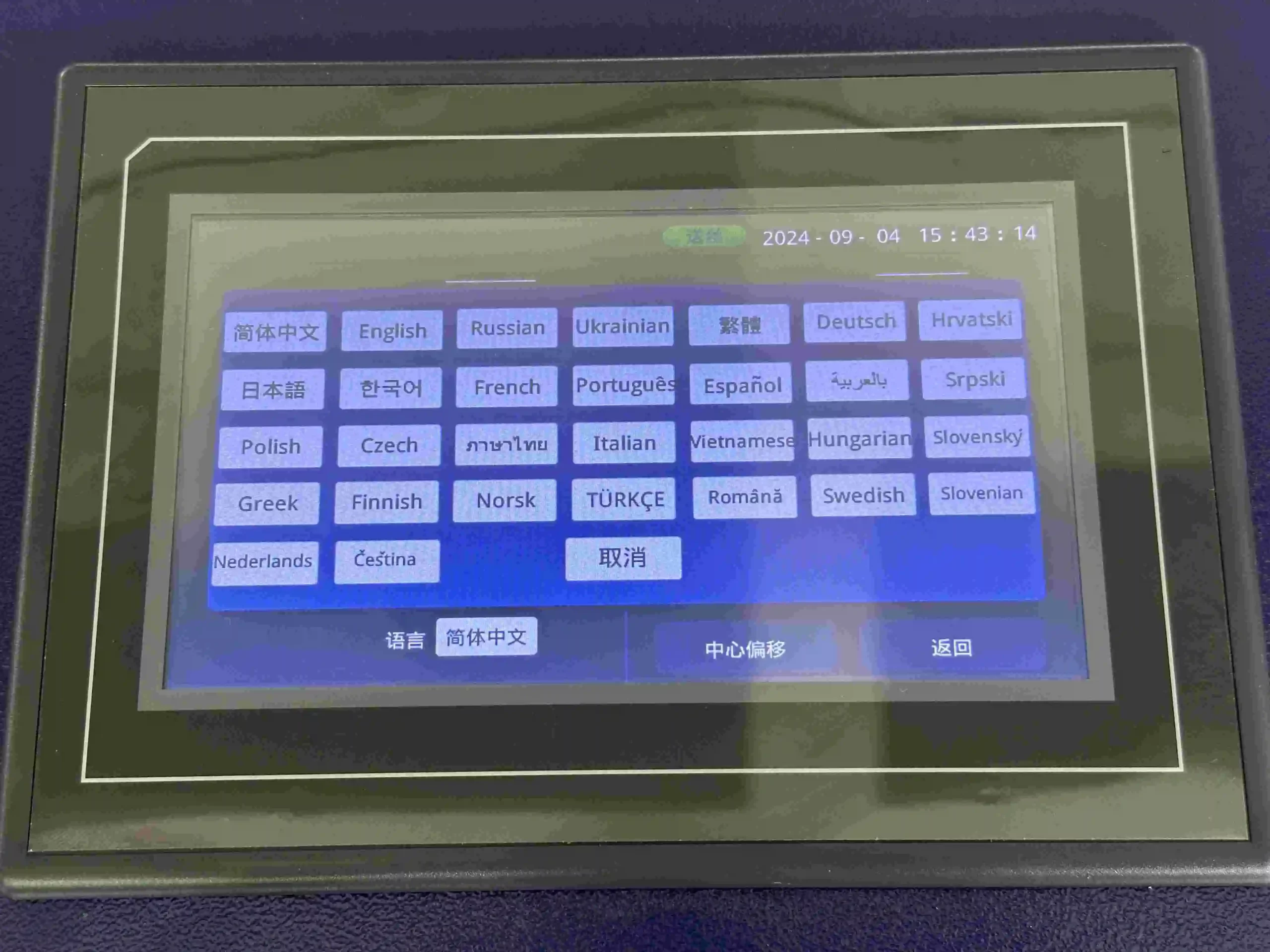

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

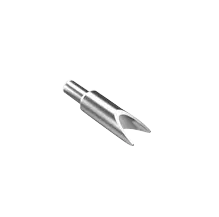

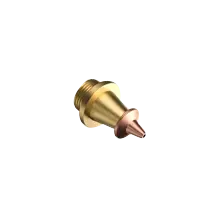

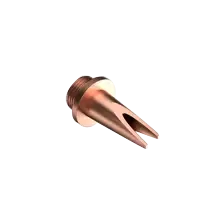

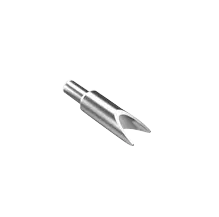

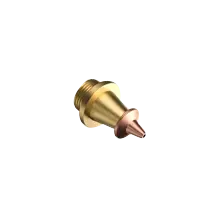

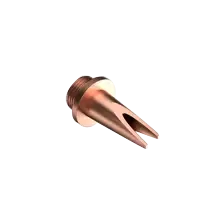

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

The 1000W- 3000W 3-in-1 laser welding machine features cleaning, cutting, and welding modes. In the metal processing and manufacturing sector, it efficiently welds and cuts various types of metals,

including stainless steel, aluminum, and copper, for the production of a wide range of metal components and products.

| -PERFORMANCE TECHNICAL PARAMETERS- | ||||

|---|---|---|---|---|

| Power | 1000W | 1500W | 2000W | 3000W |

| Laser Wavelength | 1070nm | |||

| Laser Type | Continuous | |||

| Cooling mode | Water Cooling | |||

| Voltage | 220V, 50/60Hz | 380V, 50/60Hz | ||

| Laser Lifetime | 100000h | |||

| Laser Source | MAX/Raycus/IPG/BWT | |||

| Laser Head & Control System | Sup/Qilin/Relfar/Raytools | |||

| Fiber Cable Length | 10m, Customized 20m max | |||

| Working Required Temperature | 10-35℃ | |||

| Machine Dimension | 1010*400*710mm | 1140*530*1040mm | ||

| Weight | 130kg | 150kg | ||

-PERFORMANCE TECHNICAL PARAMETERS- |

||||

| 1 Portable Handheld Laser Welding Machine | ||||

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Machine Dimension | 860*410*700mm | 1140*530*880mm | ||

| Weight | 130kg | 150kg | ||

| 2 Portable Handheld Laser Welding Machine | ||||

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Machine Dimension | 890*400*760mm | 1100*450*790mm | 1270*520*1070mm | |

| Weight | 130kg | 150kg | 180kg | |

Imagine a tool that combines power, precision, and versatility, transforming the way industries handle metal fabrication and repair. The 5 in 1 handheld metal laser welding machine is a groundbreaking innovation that integrates welding, cutting, cleaning, and more into one portable device. Whether you’re a professional welder or an industry expert, this technology redefines efficiency.

This multi-functional device merges five essential operations—welding, cutting, cleaning, engraving, and polishing—into one compact system. Its advanced laser technology ensures accuracy and ease, enabling users to achieve professional results on various metal surfaces.

Key Features

1.Multi-Functionality: Consolidates five essential tasks in one device.

2.Portability: Compact and lightweight for easy on-site use.

3.High Precision: Delivers clean, accurate results with minimal material wastage.

4.Eco-Friendly: Eliminates the need for chemicals or consumables.

5.User-Friendly: Intuitive controls simplify complex tasks.

The machine employs laser beams to deliver high-intensity energy to a focused area. Depending on the operation mode, it can weld metals, cut through surfaces, clean contaminants, engrave designs, or polish finishes with exceptional precision.

Core Functions Explained

1.Laser Welding: Melts and fuses materials for strong, seamless joints.

2.Laser Cutting: Provides precise cuts with minimal thermal impact.

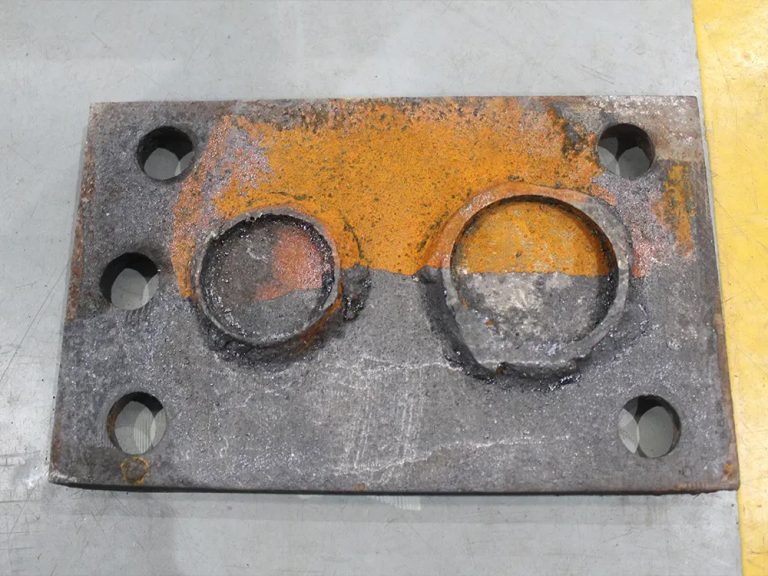

3.Laser Cleaning: Removes rust, paint, or debris without damaging the base material.

4.Laser Engraving: Creates intricate designs or markings on metal surfaces.

5.Polishing: Smooths and refines metal finishes for a professional look.

Read More

1. Industrial Metal Fabrication

Perfect for creating, assembling, or repairing metal components in industries like automotive, aerospace, and manufacturing.

2. Maintenance and Repair

Easily remove rust, repair damaged parts, or restore metal structures with precision.

3. Artistic and Decorative Projects

Engrave intricate designs or create polished finishes for custom metalwork in art and architecture.

4. Electronics Manufacturing

Perform precise welding and cutting for delicate electronic components.

5. Surface Cleaning and Preparation

Remove contaminants before processes like coating, bonding, or painting.

1. Enhanced Efficiency

Combining five tools into one device saves time, reduces operational costs, and streamlines workflows.

2. Exceptional Precision

Achieve accurate results across various applications, reducing the risk of errors and material wastage.

3. Portability and Flexibility

Designed for on-site and in-factory use, offering unmatched versatility.

4. Cost Savings

Eliminates the need for separate tools and consumables, leading to significant long-term savings.

5. Environmentally Friendly

Minimizes waste and eliminates harmful chemicals, supporting sustainable practices.

1. Power Output

Select a model with adequate power to handle your specific materials and tasks efficiently.

2. Material Compatibility

Ensure the device supports the metals you frequently work with, such as stainless steel, aluminum, or titanium.

3. Portability

For professionals requiring on-site use, prioritize lightweight and compact designs.

4. User Experience

Choose a machine with intuitive controls and minimal setup requirements to maximize productivity.

5. After-Sales Support

Look for manufacturers offering robust warranties, training, and easy access to spare parts.

Traditional Welding and Cutting Tools

• Disadvantages: Often require multiple devices, leading to higher costs and slower processes.

• Advantages: Familiarity and availability in the market.

5 in 1 Laser Welding Machine

• Advantages: Combines multiple functionalities, offering faster and more efficient workflows.

• Disadvantages: Higher upfront investment but better ROI over time.

The price for these machines typically ranges between $15,000 and $70,000, depending on power output, features, and brand.

Cost Breakdown

1.Power and Performance: Higher wattage models deliver faster results but come with a premium price tag.

2.Additional Features: Automation, advanced cooling systems, or customization may increase costs.

3.Support Services: Training, installation, and warranty coverage add value to your investment.

Yes, most models feature user-friendly controls and minimal setup requirements, making them accessible to professionals and beginners alike.

While compatible with most metals, testing is recommended for rare or unique materials.

Industries such as automotive, aerospace, manufacturing, and custom metalwork see significant advantages.

With proper maintenance, these machines can last upwards of 50,000 operational hours.

The laser welding industry continues to evolve, with trends focusing on:

• AI Integration: Smarter systems for automated and adaptive operations.

• Improved Portability: Compact designs for enhanced usability.

• Cost Efficiency: Innovations driving down costs for broader adoption.

Whether you’re in industrial manufacturing, artistic metalwork, or maintenance, this machine delivers unmatched precision, efficiency, and versatility. Its multi-functional design reduces the need for separate tools, streamlines operations, and ensures top-tier results, making it a valuable investment for modern industries.