Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

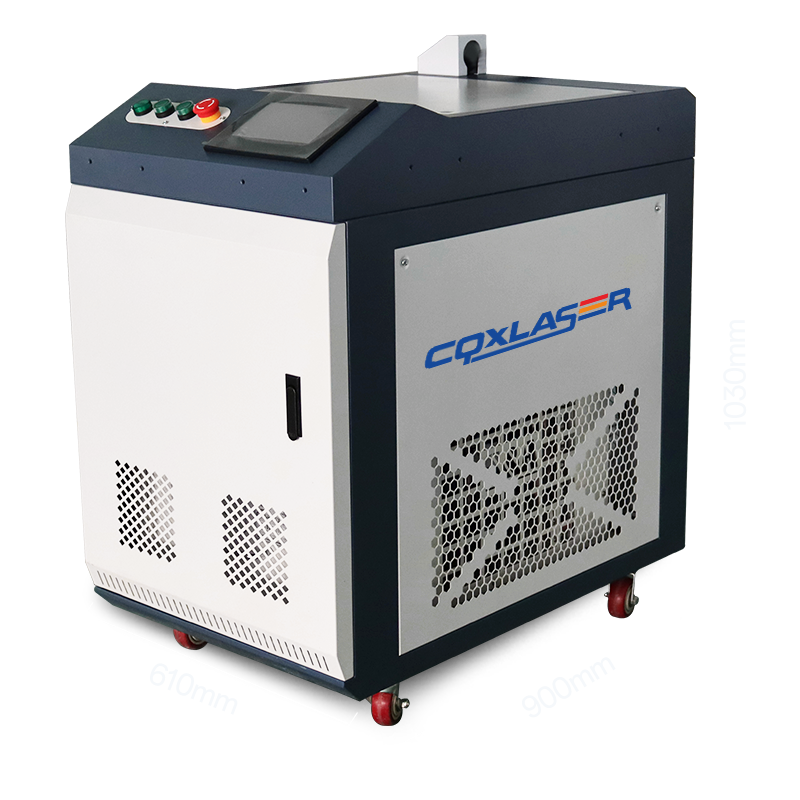

CQX-M 1-2kw

3-in-1 laser welding machine features unique welding heads, touchscreens, and buttons, ensuring seamless user operations. Incorporating welding, cleaning, and cutting functions into one machine, our 3 in 1 laser welding machine offers versatility, flexibility, and convenience.

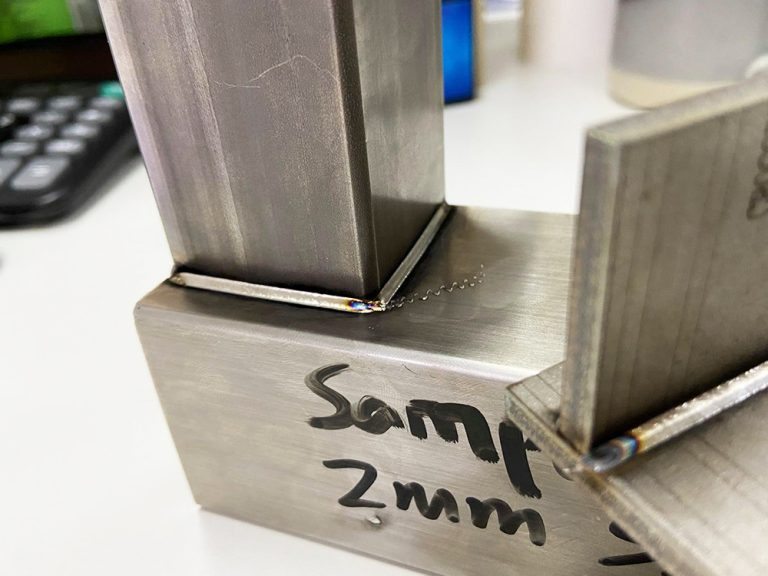

The powerful and flexible 3 in 1 laser welding machine is suitable for a wide range of metals such as stainless steel, aluminium, copper, and titanium, which can meet various welding needs.

Because of its high precision and quality welding, it is also used in precision component manufacturing.

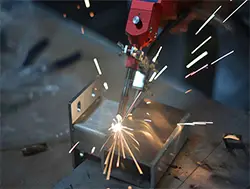

With the development of fiber laser sources, handheld laser welding machines have beenwidely used, changing the industrial welding market and making different angles andwelding processes easier, light weight, portable and easy to operate.

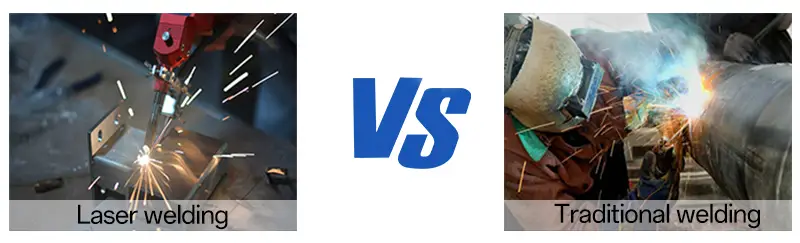

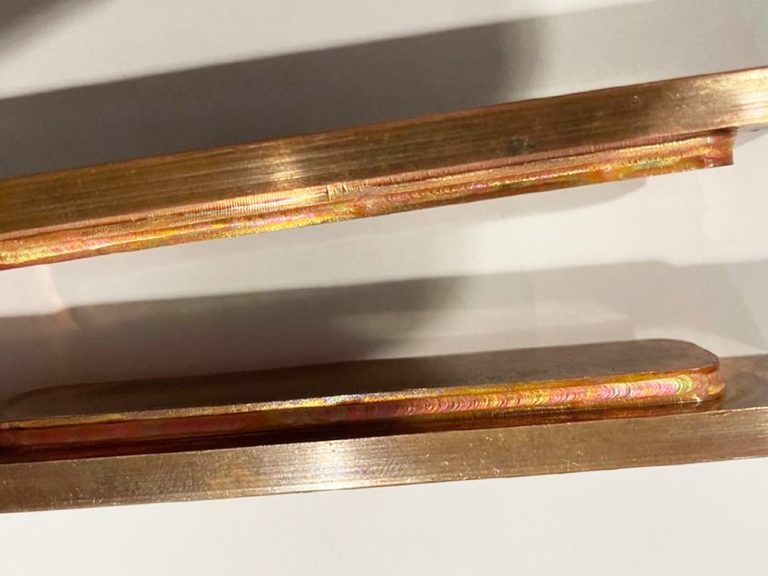

Unskill worker can get started in 10 minutes,The welding speed is 4-10times that of traditional welding, saving 3-5 professional welders.Concentrated energy, low thermal deformation, beautiful welding seamdeep penetration, high strength, can weld thin materials, can be weldedby filler wire, or welded without wire.

High professional and technical requirements, high wages forworkers, occupational diseases, large body injuries, slow weldingspeed, low efficiency, large heat influence and easy deformation, thickand irregular welds, requiring secondary polishing, large limitations.and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

|---|---|---|

| Welding speed | Common | 4-10xfaster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | Noorverylittlepolish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operators afety | Notsafe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | SixMode |

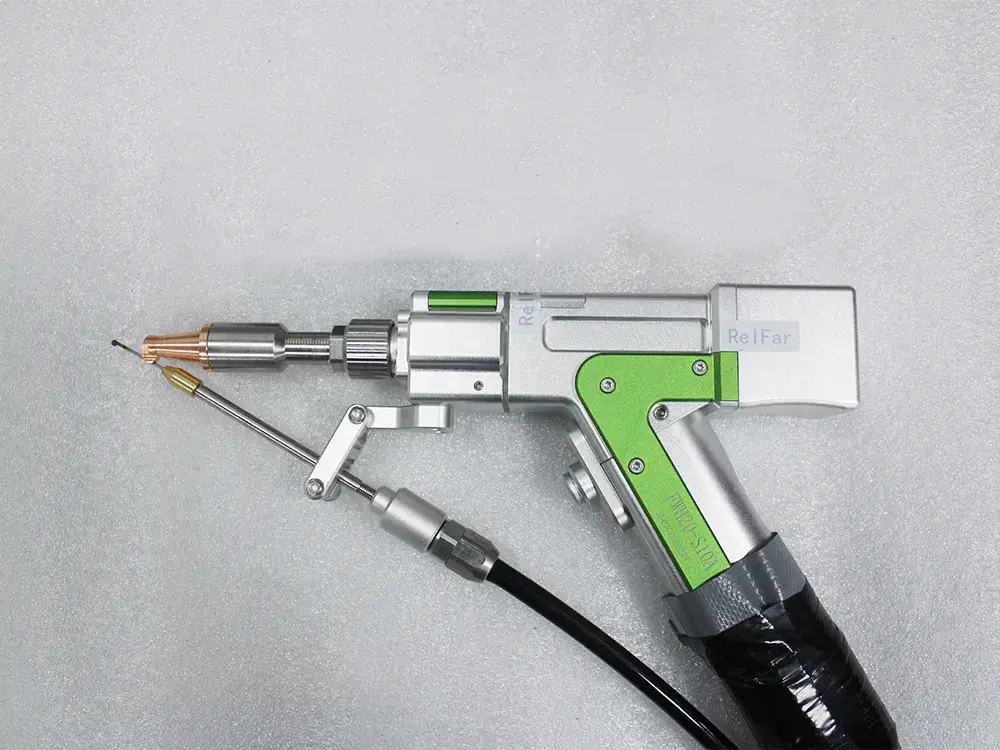

Laser head brand (Sup/Qilin/Relfar/Raytools)

Ergonomic Design:

The handheld laser head features an ergonomic design for comfortable operation and a highly flexible main thread for maneuverability.

Quick Lens Replacement & Enhanced Protection:

The pull-type system enablesa swift swap of the collimate-focusing lenseswhile dual lense protection and early fault warnings guarantee smooth operation.

Laser head brand (Sup/Qilin/Relfar/Raytools)

The handheld laser head features an ergonomic design for comfortable

operation and a highly flexible main thread for maneuverability.

Internationally renowned laser source( MAX/RayCus/IPG/BWT )

stable laser power, long life, good welding effect, beautiful welding seam.

Ensures consistent high-quality performance.

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

Internationally renowned laser source

( MAX/RayCus/IPG/BWT )

1.Compact structureo

2.High electro-opticalconversion efficiency

3.Long working life (over 100,000 hours)

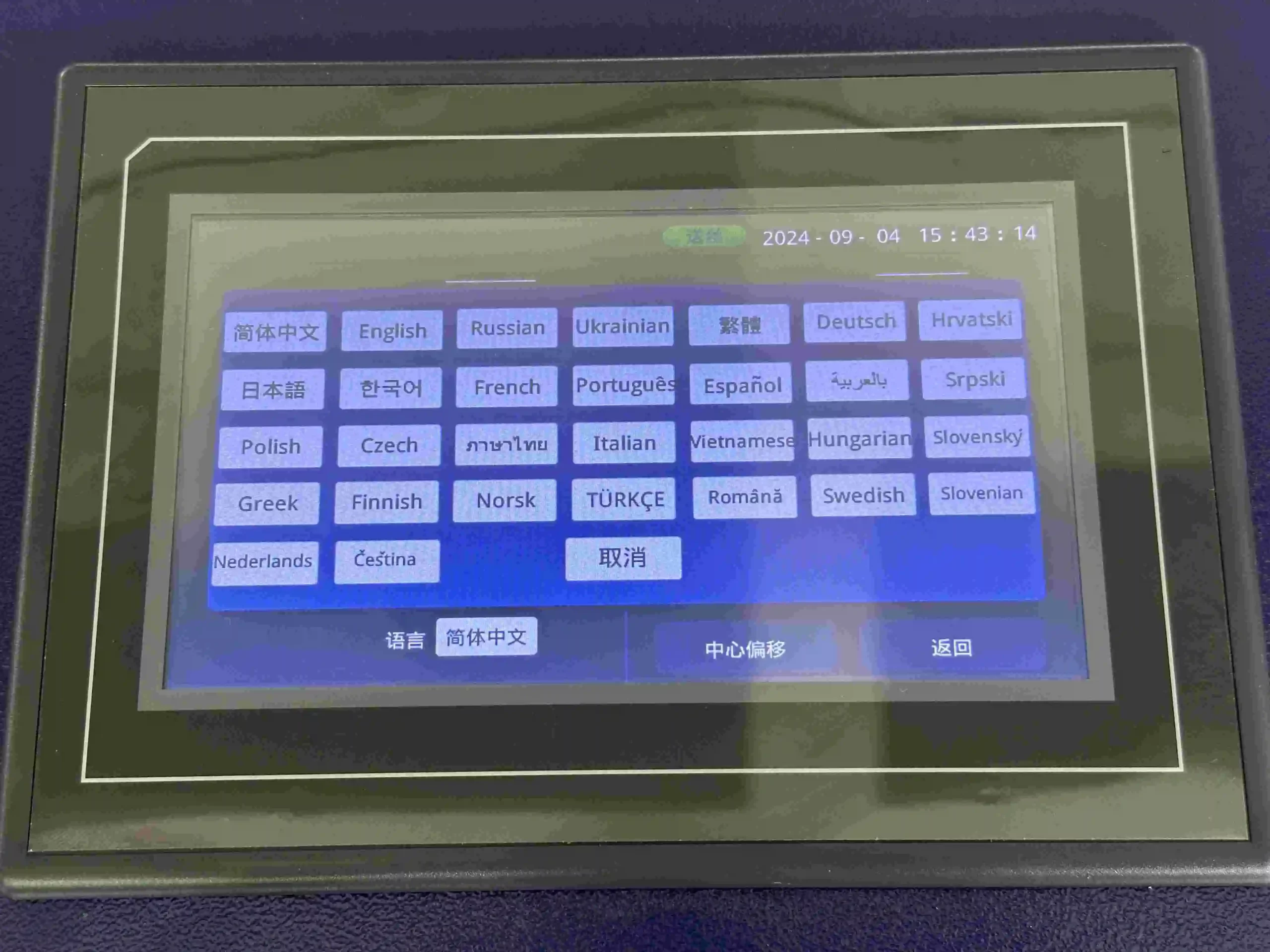

The intuitive touch screen panel simplifies the adjustment of air assist, laser and wire feeding.

The sensitive welding gun throttle can quickly discharge the laser and wire, ensuring a clean and efficient welding process without sticking.

Supports multiple language switching, including Chinese, English, Turkish, Russian and German.

Support multi-language switching

The intuitive touchscreen panel simplifies adjustment

for air assist, laser, and wire feeding.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

The chiller is integrated into the housing for ease of transport.

TEYU water cooling system or HANLl water cooling system

The chiller is built into the cabin for the ability to work

continuously without stopping to rest the machine.

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

CQX LASER offer a wire feeder as standard part for every client

help them get higher welding quality

Delivers stable wire feeding for consistent welds,

High degree of automation and labor cost saving.

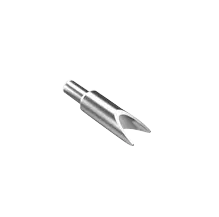

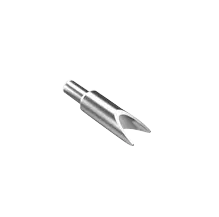

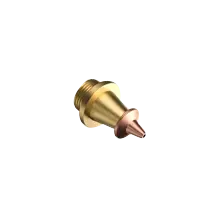

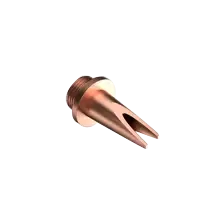

The laser welding head comes wth 8 nozzles of 6 diferen ypes, suitabie for wire diameters ranging from 0.8 to 1.2 mm, wre-free welding, cleaning, cuting, etc, meeting

welding requirements for inside and outside corners.

The 1000W- 3000W 3-in-1 laser welding machine features cleaning, cutting, and welding modes. In the metal processing and manufacturing sector, it efficiently welds and cuts various types of metals,

including stainless steel, aluminum, and copper, for the production of a wide range of metal components and products.

| -PERFORMANCE TECHNICAL PARAMETERS- | |||

|---|---|---|---|

| Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1070nm | ||

| Laser Type | Continuous | ||

| Cooling mode | Water Cooling | ||

| Voltage | 220V, 50/60Hz | ||

| Laser Lifetime | 100000h | ||

| Laser Source | MAX/Raycus/IPG/BWT | ||

| Laser Head & Control System | Sup/Qilin/Relfar/Raytools | ||

| Fiber Cable Length | 10m, Customized 20m max | ||

| Working Required Temperature | 10-35℃ | ||

| Machine Dimension | 900*610*1030mm | ||

| Weight | 150kg | ||

Precision, efficiency, and versatility—these words define the revolutionary 3 in 1 laser welder. As industries demand multi-functional solutions to save time, reduce costs, and improve results, this innovative tool emerges as the ideal answer. This article dives deep into how a 3 in 1 laser welder integrates cutting-edge features to simplify welding, cutting, and cleaning processes.

A 3 in 1 laser welder is a versatile machine designed to perform welding, cutting, and cleaning with a single device. Its advanced laser technology ensures high precision and efficiency, making it a popular choice for industries ranging from automotive to aerospace.

• Multi-Functionality: Combines welding, cutting, and cleaning in one system.

• Precision and Control: Ensures accurate and clean results on a variety of materials.

• Eco-Friendly: Reduces waste by eliminating the need for separate tools or chemicals.

• User-Friendly: Intuitive controls make it accessible even to non-experts.

The machine employs high-intensity laser beams to deliver heat or energy to a targeted area. Depending on the application, it can:

• Weld metal surfaces by melting and fusing materials.

• Cut through sheets of metal or other materials with extreme accuracy.

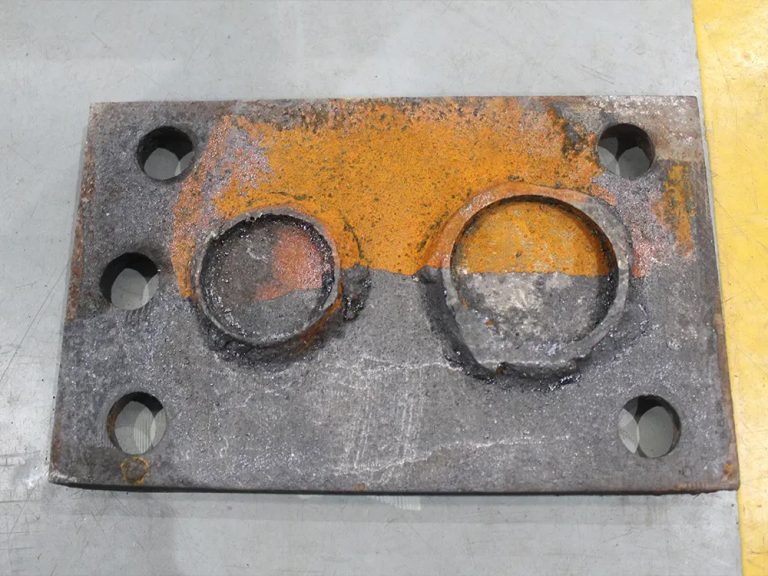

• Remove rust, paint, or contaminants via laser cleaning.

Advanced Technology

1.Laser Welding: Delivers smooth, strong joints without requiring filler material.

2.Laser Cutting: Offers precision cuts with minimal heat-affected zones.

3.Laser Cleaning: Uses laser ablation to vaporize contaminants without damaging the substrate.

Read More

1.Metal Fabrication

• Weld, cut, and clean metals like stainless steel, aluminum, and titanium.

• Ideal for industries such as automotive, shipbuilding, and construction.

2.Electronics Manufacturing

• Create precise joints and cuts for delicate components.

• Clean surfaces before bonding or coating processes.

3.Maintenance and Repair

• Repair worn or damaged parts with precise welding.

• Remove rust or contaminants to restore surfaces.

4.Aerospace and Defense

• Meet stringent standards for cutting, welding, and cleaning critical components.

• Enhance durability and precision for complex structures.

1. Efficiency and Speed

Combining three functions into one machine reduces the need for multiple tools, saving time and improving workflow.

2. Precision and Quality

Delivers exceptional results with minimal errors, ensuring high-quality output every time.

3. Cost Savings

Although the initial investment is higher, the reduced need for additional equipment and consumables offers significant long-term savings.

4. Environmental Sustainability

Laser technology eliminates the need for harmful chemicals, reducing environmental impact.

5. Versatility

Capable of handling a variety of materials and applications, making it suitable for diverse industries.

The benefits of this technology over traditional methods include:

1.Power Output

• Choose a model with adequate power for your specific applications.

• Higher power ensures faster and more efficient performance but may cost more.

2.Material Compatibility

Ensure the machine supports the materials you work with, such as metals, alloys, or composites.

3.Portability

Consider portable models if you need to perform on-site welding or cleaning tasks.

4.Ease of Use

Opt for a machine with user-friendly controls and minimal setup requirements.

5.After-Sales Support

Check for warranty, training, and maintenance services to maximize your investment.

Traditional Welding

• Relies on separate tools for cutting, cleaning, and welding.

• Often slower and less precise.

3 in 1 Laser Welders

• Combines all functions in one device.

• Offers superior speed, precision, and efficiency.

Environmental Impact

Traditional methods often use consumables or chemicals, whereas laser welders minimize waste.

The cost of a 3 in 1 laser welder ranges from $10,000 to $50,000, depending on power, features, and manufacturer.

Breakdown of Costs

1.Power Output: Higher wattage models cost more but deliver faster results.

2.Additional Features: Systems with automation or advanced cooling mechanisms are pricier.

3.Customizations: Tailored solutions for specific industries can increase the price.

Hidden Costs

• Training and Installation: Some manufacturers charge separately for these services.

• Maintenance: Routine maintenance ensures longevity and consistent performance.

No, most systems feature intuitive controls and require minimal training.

They are compatible with most metals and some non-metallic materials, but testing is recommended for specific use cases.

They are compatible with most metals and some non-metallic materials, but testing is recommended for specific use cases.

With proper maintenance, they can last over 50,000 operational hours.

The 3 in 1 laser welder represents a leap forward in efficiency, precision, and sustainability. Its ability to combine welding, cutting, and cleaning into a single system makes it a versatile tool for modern industries. Whether you’re looking to streamline workflows, reduce costs, or achieve superior results, this innovative technology offers unparalleled value.