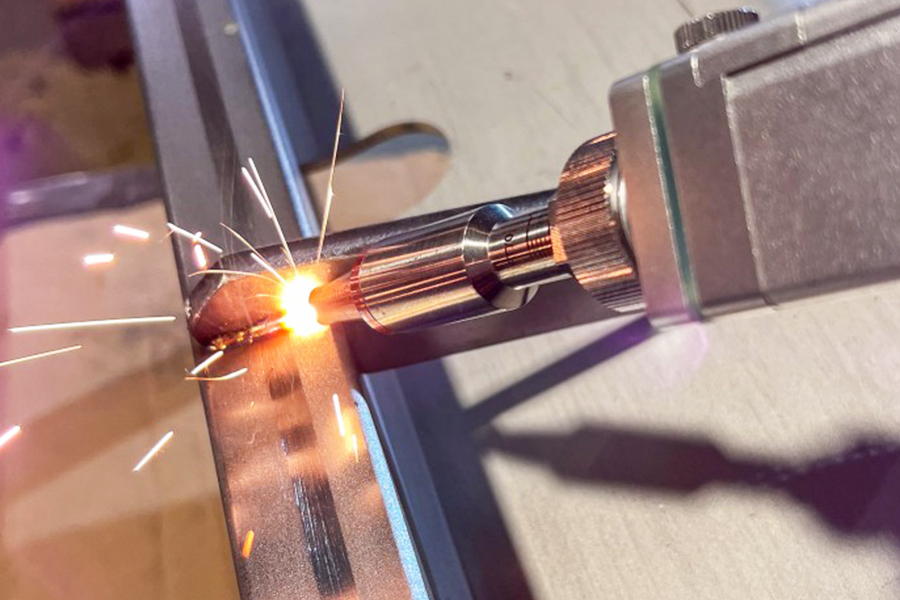

A water cooling laser welding machine uses a cooling system that circulates water to maintain the laser and other components at optimal temperatures during operation.

This helps prevent overheating, ensuring consistent performance, longer equipment lifespan, and precise welding results. Water cooling also promotes energy efficiency by dissipating heat more effectively than air cooling, which is crucial for high-power lasers.

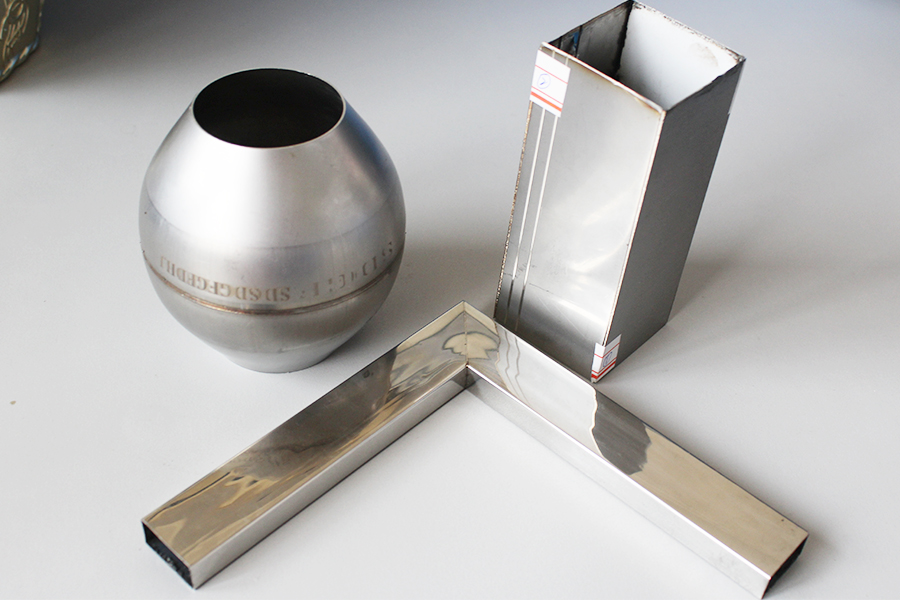

Ultimately, this system enhances productivity and ensures the quality of welds in various industries, including automotive, electronics, and aerospace.