Revolutionizing the Automotive Industry: The Power of Laser Technology

The automotive industry is at the cusp of a revolution, driven by the integration of cutting-edge laser technology. Laser beam welding, laser car cleaning, laser welding devices, and metal laser cutters are transforming the way vehicles are designed, manufactured, and maintained. In this article, we delve into the multifaceted applications of laser technology in the automotive sector, showcasing how it enhances efficiency, precision, and innovation.

The Role of Laser Beam Welding in Automotive Manufacturing

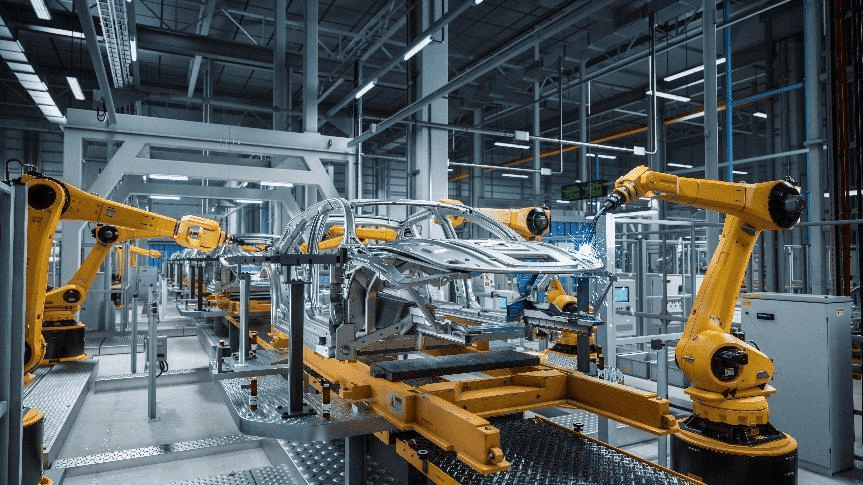

Laser beam welding has become a cornerstone in modern automotive manufacturing. This advanced welding technique uses a concentrated laser beam to join metal parts with exceptional precision and speed. It is particularly beneficial in the production of vehicle bodies, where about 50%-70% of body parts can be processed using laser welding technology. The result is stronger, lighter, and more aesthetically pleasing components.

Laser beam welding is employed in various stages of automobile production. For instance, in the assembly of car doors, the laser welding device ensures seamless joints that enhance the overall structural integrity. This process not only improves the durability of the vehicle but also contributes to its safety by ensuring that critical components are securely fastened.

Laser Welding Devices: Precision and Efficiency Combined

The advent of advanced laser welding devices has revolutionized the welding process in automotive manufacturing. These devices offer unparalleled precision, enabling manufacturers to achieve high-quality welds with minimal distortion. The use of welding laser machines has significantly reduced production times while maintaining the highest standards of quality.

Hand-held laser welding devices have further expanded the versatility of laser technology in the automotive sector. These portable units allow for on-site repairs and maintenance, providing a practical solution for complex welding tasks. They are particularly useful in scenarios where traditional welding equipment may be impractical or impossible to use.

Metal Laser Cutters: Transforming Automotive Design and Manufacturing

Metal laser cutters are indispensable tools in the automotive industry, enabling manufacturers to cut complex shapes and designs with extreme accuracy. This technology is used extensively in the production of chassis, body panels, and other structural components. The precision of metal laser cutters ensures that parts fit together perfectly, reducing the need for adjustments and rework.

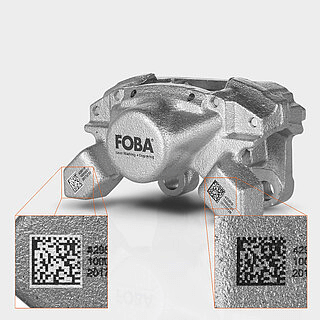

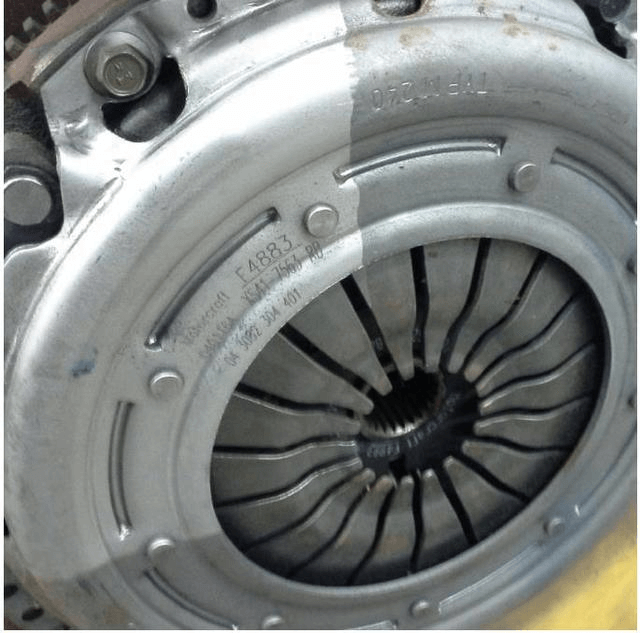

The use of fibre laser marking in conjunction with metal laser cutters allows for the permanent marking of parts with serial numbers, barcodes, and other identification information. This enhances traceability and quality control throughout the production process, ensuring that each component meets stringent industry standards.

Applications of Laser Technology in Automotive Parts Manufacturing

Laser Welding in Car Body Assembly

Car body assembly is one of the most critical stages in automotive manufacturing, and laser welding plays a vital role here. The process involves the use of robotic arms equipped with laser welding devices to achieve rapid and precise welding of the car body. This method allows for high-speed production, with welding speeds reaching up to 4.8 meters per minute. The result is a seamless, robust car body that meets the highest quality standards.

Laser Processing in Automotive Safety Components

Safety is paramount in automotive manufacturing, and laser technology ensures that safety components are manufactured to the highest standards. Laser welding, laser cutting, and fibre laser marking are used to produce airbags, bumpers, and other critical safety parts. The precision of laser processing ensures that these components meet the rigorous demands of automotive safety regulations.

For example, the welding laser machine is used to weld airbag components with high precision, ensuring that the airbags function correctly in the event of a collision. Similarly, laser cutting technology is employed to create precise openings in bumpers, which are essential for their proper installation and function.

Laser Applications in Automotive Seat Manufacturing

Automotive seats are crucial for passenger comfort and safety. Laser technology is used extensively in the manufacturing of seat components. Laser welding is employed to join seat frames and adjusters, ensuring robust and reliable connections. The laser weld process provides a clean, strong joint that enhances the overall safety and durability of the seats.

In addition to welding, laser cutting is used to produce intricate seat components, such as slide rails and brackets. The precision of laser cutting ensures that these parts fit together perfectly, reducing the need for manual adjustments and enhancing the overall assembly efficiency.

Laser Technology in Automotive Door Systems

Car doors are complex components that require high precision in their manufacturing. Laser technology is used to achieve the necessary accuracy and quality. Laser welding devices are used to weld door panels and frames, ensuring a secure and aesthetically pleasing connection. The use of metal laser cutters allows for the precise cutting of door components, ensuring that they fit together seamlessly.

Laser marking is also used in door manufacturing to label parts with essential information, such as part numbers and manufacturing dates. This enhances traceability and quality control, ensuring that each door component meets the required standards.

The Future of Laser Technology in the Automotive Industry

The integration of laser technology in the automotive industry is set to grow, driven by advancements in Industry 4.0 and artificial intelligence. The future of automotive manufacturing will see increased use of automated and digital laser processes, enhancing cutting speed, accuracy, and quality. This will enable manufacturers to produce vehicles more efficiently, reducing costs and improving overall quality.

For instance, laser beam welding will continue to evolve, with new advancements allowing for even faster and more precise welding. Laser car cleaning will become more prevalent, offering a sustainable and efficient solution for maintaining vehicle components. The development of more advanced laser welding devices and metal laser cutters will further enhance the capabilities of automotive manufacturers.

Conclusion

Laser technology is revolutionizing the automotive industry, offering unprecedented precision, efficiency, and versatility. From laser beam welding and laser car cleaning to the use of advanced laser welding devices and metal laser cutters, these technologies are transforming the way vehicles are designed, manufactured, and maintained. By embracing these innovations, automotive manufacturers can enhance their production capabilities, ensuring that they stay ahead in an increasingly competitive market.

Investing in laser technology is not just about keeping up with the competition; it’s about setting new standards in quality and efficiency. As the automotive industry continues to evolve, the integration of laser technology will play a crucial role in shaping the future of manufacturing. Whether it’s welding, cutting, cleaning, or marking, laser technology offers the tools needed to drive the industry forward.