Navigating the Future: The Revolutionary Role of Laser Machines in Shipbuilding

Imagine a world where the vast expanses of ocean are traversed by vessels crafted with unparalleled precision and efficiency. Envision ships built with meticulous attention to detail, where every weld, cut, and mark is executed with laser-like accuracy. Welcome to the future of shipbuilding, powered by the revolutionary capabilities of fiber laser welding, laser rust cleaners, laser marking machines, and fiber laser cutters. In this comprehensive exploration, we delve into how these advanced technologies are transforming the shipbuilding industry, enhancing quality, efficiency, and sustainability.

The Evolution of Shipbuilding: From Rivets to Lasers

Shipbuilding has come a long way from the days of wooden hulls and hand-forged rivets. Today, the industry is embracing cutting-edge technologies that promise to revolutionize every aspect of vessel construction. Among these advancements, laser technology stands out for its precision, speed, and versatility.

The Power of Fiber Laser Welding in Shipbuilding

Fiber laser welding is at the forefront of technological advancements in shipbuilding. This process uses a high-powered laser beam to join materials with unmatched precision and strength.

- Structural Integrity: The structural components of ships, such as hulls and frames, require robust and durable connections. Fiber laser welding ensures these connections are strong and resistant to harsh marine environments, significantly enhancing the vessel’s longevity.

- Efficiency and Speed: Traditional welding methods can be time-consuming and labor-intensive. Fiber laser welding, on the other hand, is much faster and requires less manual intervention, speeding up the production process without compromising on quality.

- Precision: The precision of fiber laser welding allows for intricate designs and complex geometries that are often required in modern shipbuilding. This precision also minimizes material waste, contributing to cost savings.

- Minimal Heat Distortion: One of the significant advantages of fiber laser welding is the minimal heat distortion it causes. This is crucial in shipbuilding, where maintaining the integrity of metal components is essential.

Laser Rust Cleaners: A Revolution in Maintenance

Laser rust cleaners are transforming the way ships are maintained, offering a clean, efficient, and environmentally friendly alternative to traditional rust removal methods.

- Eco-Friendly: Traditional rust removal often involves harsh chemicals and abrasive materials that can harm the environment. Laser rust cleaners use a non-contact, laser-based approach that eliminates rust without the need for harmful substances.

- Precision Cleaning: These cleaners provide precision cleaning, targeting only the rust and leaving the underlying material intact. This is particularly important for preserving the structural integrity of ship components.

- Reduced Downtime: The efficiency of laser rust cleaners means that ships spend less time in maintenance and more time in operation. This is a significant advantage for shipping companies looking to maximize their fleet’s availability.

- Safety: Using lasers for rust removal reduces the risks associated with traditional methods, such as exposure to toxic chemicals and the physical strain of manual cleaning.

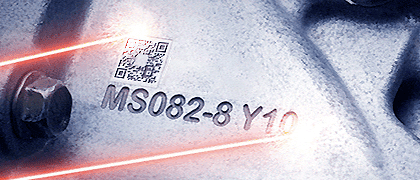

The Role of Laser Marking Machines in Shipbuilding

Laser marking machines play a crucial role in ensuring traceability and compliance in shipbuilding. These machines use lasers to engrave permanent marks on various materials, providing essential information about the ship’s components.

- Traceability: In the complex supply chain of shipbuilding, traceability is crucial. Laser marking machines ensure that every component is clearly marked with serial numbers, batch numbers, and other critical information, facilitating easy tracking and quality control.

- Compliance: The maritime industry is subject to stringent regulations. Laser marking ensures that all parts are compliant with international standards, reducing the risk of non-compliance penalties.

- Durability: The marks created by laser marking machines are highly durable, withstanding harsh marine environments without fading or becoming illegible. This ensures that important information remains accessible throughout the ship’s lifecycle.

- Customization: Laser marking machines allow for the customization of marks, including logos and branding, which can enhance the aesthetic appeal and brand recognition of vessels.

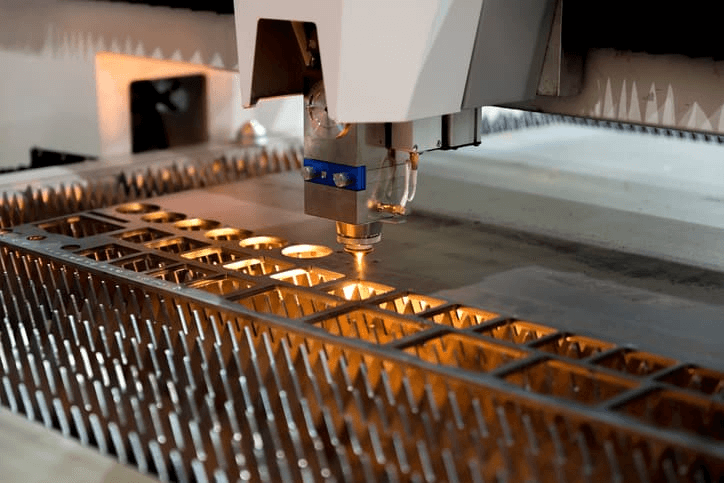

Precision Cutting with Fiber Laser Cutters

Fiber laser cutters are revolutionizing the cutting processes in shipbuilding, providing unmatched precision and versatility.

- High Precision: Fiber laser cutters offer incredible precision, allowing for the cutting of intricate shapes and designs that are essential in modern shipbuilding. This precision reduces the need for further processing and ensures a perfect fit for assembled parts.

- Versatility: These cutters can handle a wide range of materials, including steel, aluminum, and composite materials, making them ideal for various shipbuilding applications.

- Efficiency: The speed and accuracy of fiber laser cutters significantly reduce production times, enabling shipbuilders to meet tight deadlines without sacrificing quality.

- Reduced Waste: The precision of laser cutting minimizes material waste, contributing to cost savings and environmental sustainability. This is particularly important in an industry where material costs can be substantial.

Applications and Benefits Across the Shipbuilding Process

Hull Construction

The hull is the backbone of any ship, and its construction requires the highest levels of precision and strength. Fiber laser welding ensures that the steel plates and frames that make up the hull are joined flawlessly, providing a robust structure that can withstand the rigors of the sea.

Deck and Superstructure

The deck and superstructure of a ship house critical components and systems. Using fiber laser cutters, shipbuilders can create the intricate designs and precise cuts needed for these areas, ensuring a perfect fit and seamless assembly.

Engine Room and Machinery Spaces

The engine room is the heart of a ship, containing complex machinery and systems. Laser marking machines ensure that every component is clearly labeled for easy identification and maintenance, while fiber laser welding provides the strength and precision needed for assembling critical systems.

Maintenance and Repairs

Maintenance is a constant in the maritime industry. Laser rust cleaners provide an efficient and environmentally friendly solution for removing rust and other contaminants, extending the lifespan of ship components and reducing downtime.

Conclusion: Navigating Towards a Laser-Driven Future

The applications of fiber laser welding, laser rust cleaners, laser marking machines, and fiber laser cutters in shipbuilding are vast and transformative. These technologies not only enhance the precision, efficiency, and quality of ship construction and maintenance but also contribute to sustainability and environmental protection.

As the shipbuilding industry continues to evolve, embracing these advanced laser technologies will be crucial for staying competitive and meeting the demands of modern maritime operations. By integrating laser technology into their processes, shipbuilders can achieve new levels of excellence, ensuring that the vessels of the future are built with unparalleled precision and care.