The Role of Handheld Laser Welding and Laser Metal Cleaning in Transforming Fitness Equipment Manufacturing

Handheld laser welding is revolutionizing the way fitness equipment is made. This innovative technology is not just an upgrade in welding—it’s a game-changer that is enhancing both the manufacturing process and the final product. In the competitive world of fitness equipment production, manufacturers are constantly seeking faster, more efficient, and more sustainable ways to deliver high-quality products. With the advent of handheld laser welding and laser metal cleaning, the industry is now equipped with the tools to meet these demands in ways that were once unimaginable.

At the forefront of this transformation is CQX LASER, a leader in laser technology solutions, providing manufacturers with cutting-edge tools that are driving precision, speed, and efficiency. These technologies are not only improving the quality of the equipment but also optimizing the overall production process, contributing to a more sustainable and cost-effective future for the industry.

1.Handheld Laser Welding: A Breakthrough for Fitness Equipment Manufacturers

Handheld laser welding is quickly becoming the method of choice for fitness equipment manufacturers, thanks to its remarkable precision and versatility. Unlike traditional welding techniques, which can be cumbersome and time-consuming, handheld laser welding allows for quick, high-quality welds on a wide variety of materials.

Precision and Flexibility for Complex Designs

Fitness equipment often involves intricate parts that require precise welding, especially when it comes to machines with multiple components or complex geometries. Handheld laser welders are designed to tackle these challenges with ease. The concentrated laser beam can weld in confined or hard-to-reach areas, making it perfect for the intricate structures found in machines like treadmills, weight machines, and bicycles. The technology allows for highly accurate joints, ensuring that the final product is both structurally sound and aesthetically pleasing.

Faster Production, Lower Costs

One of the key benefits of handheld laser welding in fitness equipment manufacturing is the speed at which it operates. Laser welding is faster than traditional welding methods, reducing production time and improving efficiency. Manufacturers can now produce equipment at a higher rate without sacrificing quality. Additionally, the minimal heat affected zone (HAZ) produced by lasers reduces the likelihood of warping and material waste, further lowering costs.

Cleaner, Safer Manufacturing Environment

In comparison to conventional welding, handheld laser welding offers a cleaner working environment. Traditional welding often produces harmful fumes and requires the use of additional safety equipment, whereas laser welding generates fewer emissions and does not require filler materials. This makes it a safer and more environmentally friendly choice for manufacturers concerned with worker safety and compliance with increasingly stringent environmental regulations.

2.Laser Metal Cleaning: The Perfect Complement to Welding in Fitness Equipment Production

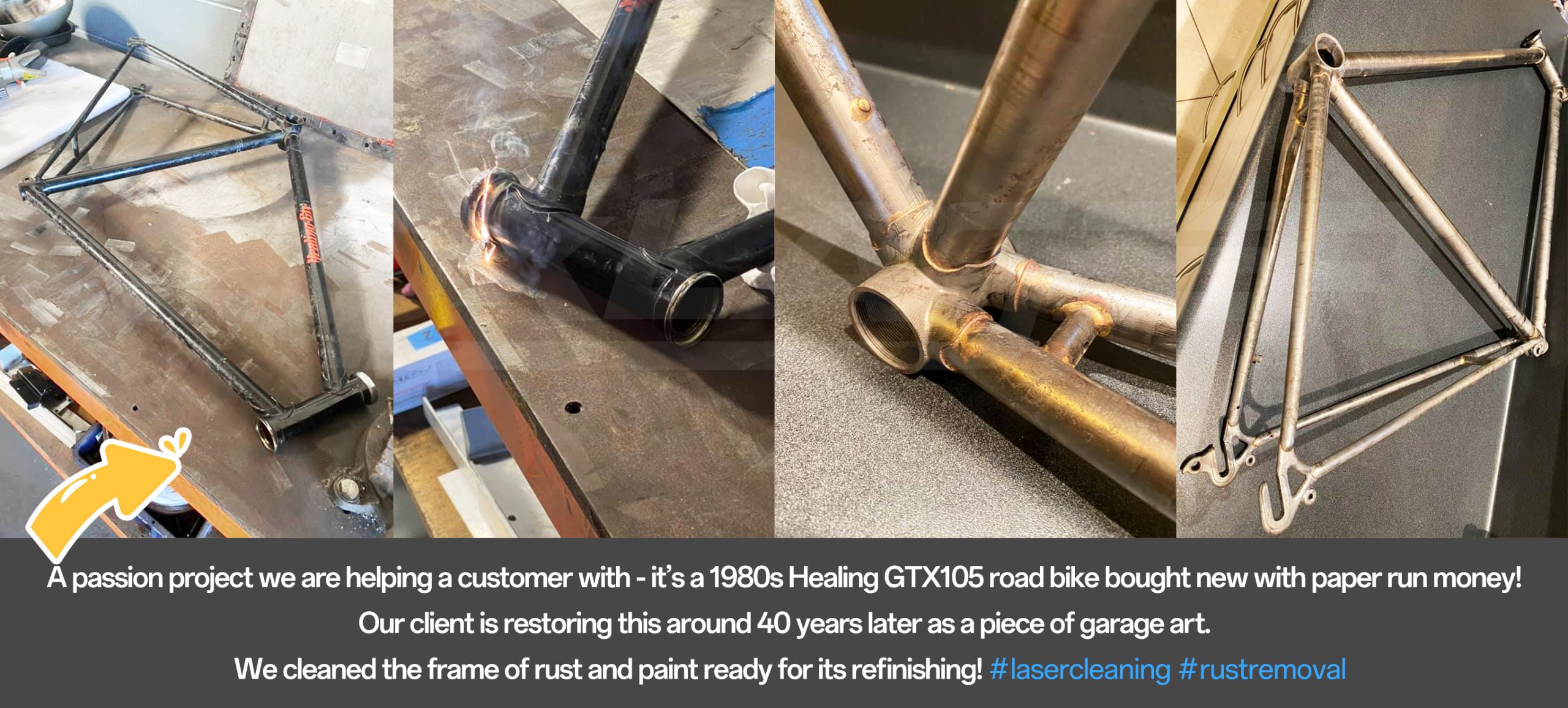

While welding focuses on joining materials, laser metal cleaning works to prepare surfaces for further processing. In the fitness equipment industry, this process is essential for ensuring that metal parts are free from contaminants like rust, oils, or dirt before the finishing or coating stages.

Efficiency in Surface Preparation

Laser metal cleaning works by using high-intensity laser pulses to remove unwanted contaminants from metal surfaces. This method is highly efficient, as it targets specific contaminants without affecting the base material. In the case of fitness equipment, where surface cleanliness is crucial for longevity and appearance, laser cleaning ensures that every piece is prepared for subsequent processes such as painting, coating, or welding.

Eco-Friendly and Cost-Effective

Unlike traditional cleaning methods, such as sandblasting or chemical cleaning, laser metal cleaning does not require harsh chemicals or abrasive materials. This not only makes it more environmentally friendly but also reduces the costs associated with purchasing and disposing of cleaning agents. Additionally, the process is incredibly precise, meaning that manufacturers can achieve a high level of cleanliness without wasting resources or time.

Enhanced Durability and Finish Quality

Clean surfaces are critical to ensuring the durability and quality of fitness equipment. Metal that is free of contaminants is more likely to withstand the wear and tear of frequent use. Laser cleaning improves adhesion for coatings, paints, and finishes, helping manufacturers deliver products that not only look better but also last longer. This results in fitness equipment that retains its aesthetic appeal and functional integrity over time, even under the demanding conditions typical of gyms or home use.

3.Integrating Handheld Laser Welding and Laser Metal Cleaning for Maximum Efficiency

When combined, handheld laser welding and laser metal cleaning create a streamlined and highly efficient manufacturing process that enhances both the quality of the fitness equipment and the productivity of the factory.

A Comprehensive Solution for Fitness Equipment Production

Laser welding and laser cleaning work together to provide a comprehensive solution for manufacturers. After laser cleaning the metal surfaces, the components can be welded with precision, ensuring that the final product is strong, clean, and visually appealing. This integrated approach minimizes the need for additional finishing processes, reducing time and labor costs while improving the overall quality of the equipment.

Sustainability in Manufacturing

Both technologies contribute to a more sustainable production process. Handheld laser welding uses minimal consumables and reduces material waste, while laser metal cleaning eliminates the need for harmful chemicals and abrasives. Together, they create a closed-loop system that reduces the carbon footprint of the manufacturing process, helping companies adhere to sustainability goals while still maintaining high production standards.

4.CQX LASER: Leading the Way in Innovation for Fitness Equipment Manufacturers

As the fitness equipment industry evolves, the role of advanced technologies like handheld laser welding and laser metal cleaning will only become more critical. Companies that adopt these technologies are better positioned to meet the growing demand for high-quality, durable, and aesthetically pleasing fitness equipment.

CQX LASER is leading the way by offering state-of-the-art laser solutions that allow manufacturers to stay competitive in this fast-paced industry. With the combination of handheld laser welding and laser metal cleaning, CQX LASER is helping businesses optimize their production lines, reduce costs, and create better products.

By integrating handheld laser welding and laser metal cleaning into their production processes, fitness equipment manufacturers can achieve new levels of efficiency, sustainability, and quality. As the industry continues to grow, those who embrace these cutting-edge technologies will be well-positioned to lead the way in the future of fitness equipment manufacturing.