Introduction:

The construction industry is a vibrant, fast-paced realm where precision, efficiency, and durability are essential. As technology continues to evolve, the methods used to craft, clean, and maintain construction materials have shifted dramatically. Amid this transformation, laser welds and the handheld laser cleaning machine have emerged as game-changers, offering solutions that are not only effective but also sustainable. These technologies offer unparalleled advantages in areas like structural integrity, material longevity, and overall productivity—turning what once were labor-intensive tasks into streamlined processes.

Imagine a world where welding is no longer a slow, messy process, where rust and corrosion vanish with the touch of a beam of light. This is the promise of laser technology in construction, pushing the boundaries of what’s possible, redefining industries, and creating a foundation for a more efficient future. With these advancements, the construction industry has entered a new era—an era where precision meets power, and innovation fuels progress. Laser welds and handheld laser cleaning machines are at the forefront of this revolution, offering construction professionals solutions that are faster, cleaner, and more reliable than ever before.

Laser Welding in Construction: Revolutionizing Structural Integrity

Laser welding in construction is no longer a mere trend; it is an essential part of modern construction practices. In the past, welding was often a labor-intensive process that required skilled workers, long hours, and a considerable amount of cleanup. Traditional methods such as arc welding have their place, but they are limited in the precision and quality they can achieve—especially when working with delicate materials or in confined spaces.

Laser welds, on the other hand, offer a higher level of precision and control, enabling construction professionals to achieve near-perfect joints between metals, reducing the risk of errors and enhancing the overall quality of the work. The ability to weld at high speeds without compromising the strength of the materials involved is one of the primary reasons laser welding has become so valuable in construction.

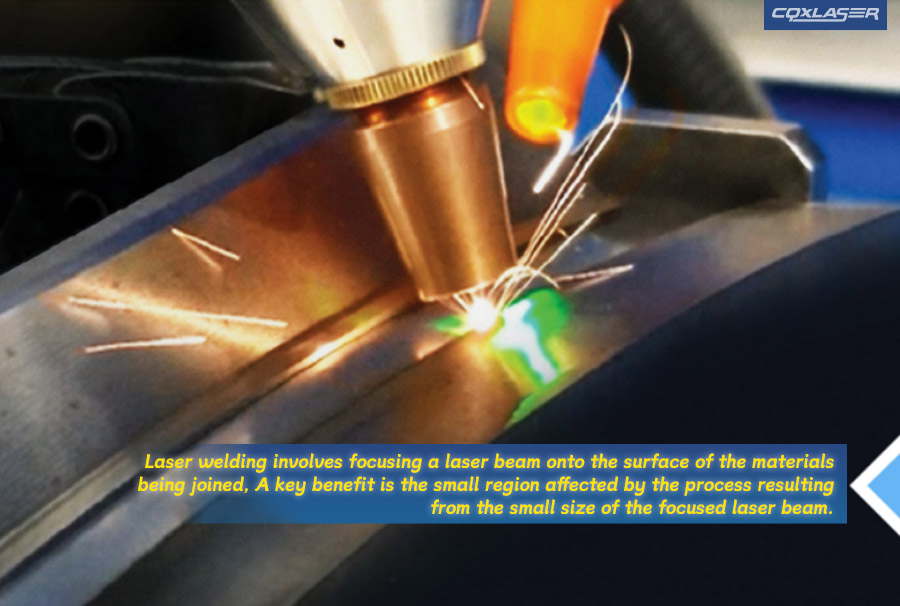

Laser welding works by focusing a high-powered laser beam onto the material, melting the metal at a precise point, and allowing it to fuse with minimal heat distortion. The result is a strong, clean joint with minimal heat-affected zones—an essential factor in maintaining the structural integrity of construction materials. This level of precision allows for welding in a range of construction applications, from bridges and skyscrapers to intricate framework and smaller components.

Moreover, laser welds can be applied to a wide variety of materials, including steel, aluminum, and titanium—commonly used in the construction industry for their strength, durability, and resistance to corrosion. These materials are often used in high-stress areas like steel beams, frames, and supports, where the quality of the weld is of utmost importance. With the precision of laser welding, these structures can be built with confidence, knowing that the welds will provide the necessary strength and reliability.

The benefits extend beyond just the quality of the welds. Laser welding reduces the time needed for each weld, increasing efficiency and reducing labor costs. Furthermore, because laser welding produces less heat than traditional welding methods, there is less risk of warping or damaging the surrounding materials. This makes laser welding an ideal solution for projects requiring high-quality welds in tight spaces or with complex geometries.

Handheld Laser Cleaning Machines: Redefining Surface Cleaning in Construction

One of the most significant challenges in construction is maintaining the surfaces of steel and other materials exposed to harsh environmental conditions. Rust, scale, and other contaminants accumulate over time, compromising the aesthetics, integrity, and functionality of structural elements. Traditionally, these contaminants were removed using abrasive methods, chemicals, or sandblasting techniques, all of which are not only time-consuming but also pose environmental risks.

Enter the handheld laser cleaning machine—a technology that is rapidly gaining traction in the construction industry as an efficient, eco-friendly solution for surface cleaning. Laser cleaning works by using a high-powered laser beam to target and remove contaminants such as rust, oil, dirt, and paint from surfaces without damaging the underlying material. The laser beam’s energy is absorbed by the contaminants, causing them to vaporize or be blown away by the pressure from the laser’s focused light.

The precision of handheld laser cleaning machines is unparalleled. Unlike traditional methods, which can damage the underlying material, laser cleaning removes only the contaminants, leaving the base material intact. This makes it ideal for cleaning delicate structures, historical buildings, or other applications where preserving the integrity of the surface is essential.

In construction, the handheld laser cleaning machine offers several advantages over traditional methods. First, it eliminates the need for chemicals, abrasives, or water, making it an environmentally friendly solution. Additionally, laser cleaning is a non-contact process, meaning there is no risk of scratching or marring the surface. This makes it perfect for cleaning steel beams, rebar, and other structural components used in construction.

Laser cleaning also provides significant time savings. Traditional methods can take hours or even days to remove rust and other contaminants, but a handheld laser cleaning machine can accomplish the same task in a fraction of the time. This efficiency not only reduces labor costs but also allows construction projects to stay on schedule.

The Future of Construction with Laser Technology

The continued integration of laser welds and handheld laser cleaning machines in the construction industry represents a significant shift in how buildings and infrastructure are designed, built, and maintained. As the demand for more sustainable, efficient, and high-quality construction methods grows, these laser technologies will continue to play a crucial role in meeting those needs.

For example, laser welds will continue to enable faster construction timelines and improved structural reliability. As the technology advances, lasers will be able to weld even more complex materials and geometries, allowing for greater innovation in architectural design and construction techniques. Furthermore, laser technology will be instrumental in the growing focus on sustainable construction practices, as it reduces waste and minimizes the environmental impact of construction processes.

Similarly, handheld laser cleaning machines will become even more widespread as construction professionals seek to reduce their reliance on traditional, less eco-friendly cleaning methods. The ability to clean surfaces more effectively and efficiently while protecting the environment will continue to drive the adoption of laser cleaning technologies in the industry.

As companies like CQX continue to develop cutting-edge laser solutions, the construction industry is poised to enter an era where lasers are used not only for their precision but also for their ability to increase productivity, reduce costs, and enhance the longevity of construction materials. The combination of laser welds and handheld laser cleaning machines will undoubtedly shape the future of the construction industry, creating a more efficient, sustainable, and technologically advanced world.

This article, while addressing the revolutionary impact of laser technology in construction, showcases how laser welds and handheld laser cleaning machines can transform the way buildings and infrastructure are built, cleaned, and maintained. The integration of these technologies has the potential to enhance the industry’s efficiency, quality, and sustainability—setting the stage for a new era in construction.