Sky-High Precision: The Role of Laser Machines in the Aerospace Industry

Imagine a realm where every aircraft is crafted with surgical precision, every component designed to withstand the most extreme conditions, and every piece engineered to ensure utmost safety and reliability. Picture a world where the technology used to create these marvels of engineering is as advanced as the aircraft themselves. This is the transformative power of laser technology in the aerospace industry. Tools like the portable laser welder, handheld laser cleaner, optical fiber laser marking machine, and steel laser cutter are revolutionizing aerospace manufacturing, enhancing quality, efficiency, and innovation.

The Evolution of Aerospace Manufacturing

The aerospace industry has evolved from rudimentary flying machines to complex aircraft that dominate the skies and beyond. As the demand for safer, more efficient, and technologically advanced aircraft grows, manufacturers are turning to cutting-edge technologies to stay ahead. Laser technology, with its precision, speed, and versatility, is at the forefront of this evolution, offering unmatched benefits that transform every stage of aerospace production.

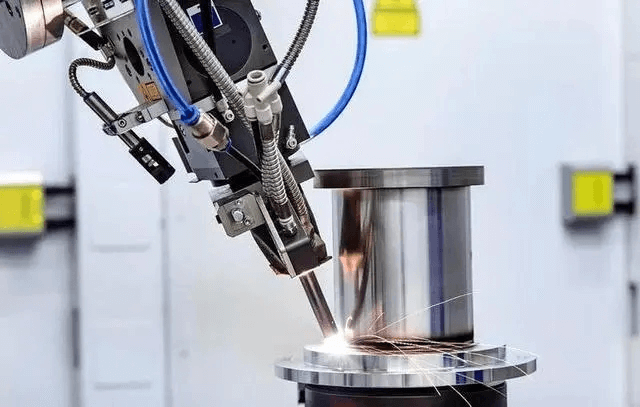

The Power of Portable Laser Welders in Aerospace

Portable laser welders are essential in the production and maintenance of high-performance aerospace components. This technology uses a focused laser beam to join materials with exceptional precision and strength.

- Stronger, More Reliable Joints: Aerospace components such as fuselage panels, engine parts, and structural supports require robust and durable joints. Portable laser welders provide strong and clean welds that enhance the longevity and reliability of these critical components.

- Precision and Accuracy: The precision of portable laser welding allows for the creation of intricate designs and complex geometries essential for modern aerospace applications. This precision minimizes material waste and ensures high-quality products.

- Enhanced Durability: The minimal heat distortion offered by portable laser welding preserves the integrity of the materials, resulting in longer-lasting components.

- Efficiency and Speed: Traditional welding methods can be slow and labor-intensive. Portable laser welders significantly speed up the welding process, increasing production rates without compromising quality.

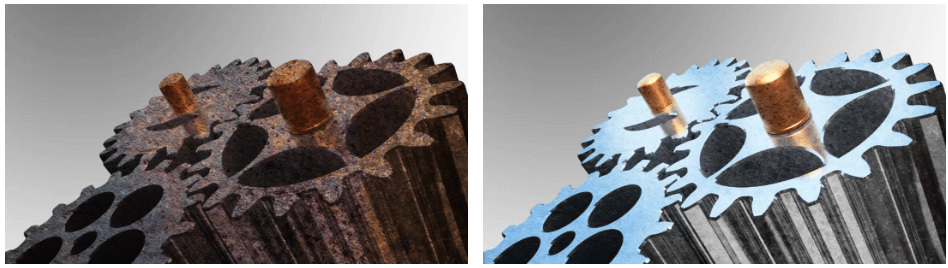

Handheld Laser Cleaners: Maintaining Quality and Longevity

Handheld laser cleaners provide an advanced, environmentally friendly solution for maintaining and preparing metal surfaces in the aerospace industry.

- Eco-Friendly Cleaning: Traditional cleaning methods often involve abrasive materials and harmful chemicals. Handheld laser cleaners use a non-contact, laser-based approach that eliminates contaminants without damaging the base material or the environment.

- Precision Cleaning: These cleaners provide precision cleaning, targeting only the unwanted materials such as rust, paint, and residues, while leaving the underlying metal intact. This precision is essential for maintaining the quality and performance of aerospace components.

- Cost-Effective Maintenance: The efficiency of handheld laser cleaners reduces the time and labor required for maintenance, leading to cost savings for manufacturers. This also extends the lifespan of aerospace components by preventing damage and degradation.

- Enhanced Surface Preparation: Clean metal surfaces are crucial for processes such as welding, coating, and marking. Handheld laser cleaners ensure that surfaces are perfectly prepared, improving the adhesion and quality of these processes.

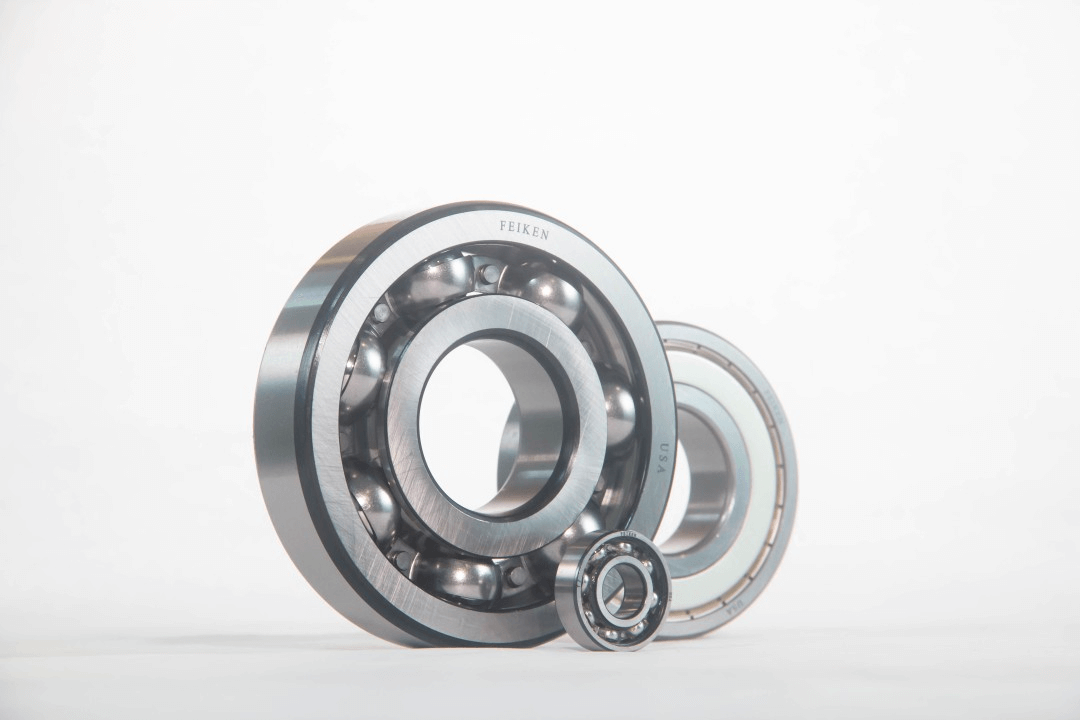

The Role of Optical Fiber Laser Marking Machines in Aerospace

Optical fiber laser marking machines play a vital role in ensuring traceability, branding, and compliance in the aerospace industry. These machines use lasers to engrave permanent marks on various materials, providing essential information about the components.

- Enhanced Traceability: In the highly regulated aerospace market, traceability is crucial. Optical fiber laser marking machines ensure that every component is clearly marked with serial numbers, batch numbers, and other critical information, facilitating easy tracking and quality control.

- Flexible Branding: Laser marking allows manufacturers to add logos, brand names, and other essential information to their products. This enhances brand recognition and adds value to aerospace components.

- Compliance: The aerospace industry is subject to stringent regulations regarding product safety and materials. Laser marking ensures that all parts are compliant with industry standards, reducing the risk of non-compliance penalties.

- Durability: The marks created by optical fiber laser marking machines are highly durable, withstanding wear, exposure to harsh conditions, and maintaining legibility over time.

Precision Cutting with Steel Laser Cutters

Steel laser cutters are at the forefront of aerospace component manufacturing, providing unmatched precision and versatility in cutting processes.

- High Precision: Steel laser cutters offer incredible precision, allowing for the cutting of intricate shapes and designs essential for modern aerospace components. This precision reduces the need for further processing and ensures a perfect fit for assembled parts.

- Versatility: These cutters can handle a wide range of materials, including steel, aluminum, and composites, making them ideal for various aerospace applications.

- Efficiency: The speed and accuracy of steel laser cutters significantly reduce production times, enabling manufacturers to meet tight deadlines without sacrificing quality.

- Reduced Waste: The precision of laser cutting minimizes material waste, contributing to cost savings and environmental sustainability. This is particularly important in an industry where material costs can be substantial.

Applications and Benefits Across the Aerospace Manufacturing Process

Fuselage Construction

The fuselage is the backbone of any aircraft, requiring high levels of precision and strength. Portable laser welders ensure that the metal panels and frames that make up the fuselage are joined flawlessly, providing a robust structure that can withstand the rigors of flight.

Engine Components

Aircraft engines comprise numerous intricate parts that must endure extreme conditions. Steel laser cutters precisely shape these components, ensuring optimal performance and reliability. Handheld laser cleaners maintain these parts, removing contaminants that could affect their operation.

Interior and Exterior Markings

Every aircraft requires detailed markings for safety, identification, and branding. Optical fiber laser marking machines provide durable and clear markings that remain legible throughout the aircraft’s lifespan. These markings include serial numbers, logos, and safety instructions.

Maintenance and Repairs

Regular maintenance is critical in the aerospace industry. Handheld laser cleaners offer a non-destructive way to clean and prepare surfaces for repairs. Portable laser welders enable precise and efficient repairs, ensuring that components meet stringent safety standards.

Conclusion: Forging the Future of Aerospace with Laser Technology

The integration of portable laser welders, handheld laser cleaners, optical fiber laser marking machines, and steel laser cutters is revolutionizing the aerospace industry. These technologies not only enhance the precision, efficiency, and quality of manufacturing processes but also contribute to sustainability and environmental protection.

As the aerospace industry continues to evolve, embracing these advanced laser technologies will be crucial for staying competitive and meeting the demands of modern aviation. By integrating laser technology into their processes, manufacturers can achieve new levels of excellence, ensuring that the aircraft of the future are built with unparalleled precision and care.