Transforming the Advertising Industry: The Unseen Power of Laser Welding and Rust Cleaning Lasers

The advertising industry, known for its relentless pursuit of innovation and high-quality designs, is now experiencing a technological revolution powered by laser welding equipment and rust cleaning lasers. These advanced tools are no longer confined to heavy industrial sectors; they have found their place in the heart of advertising production, offering new solutions for precision manufacturing, customization, and sustainability.

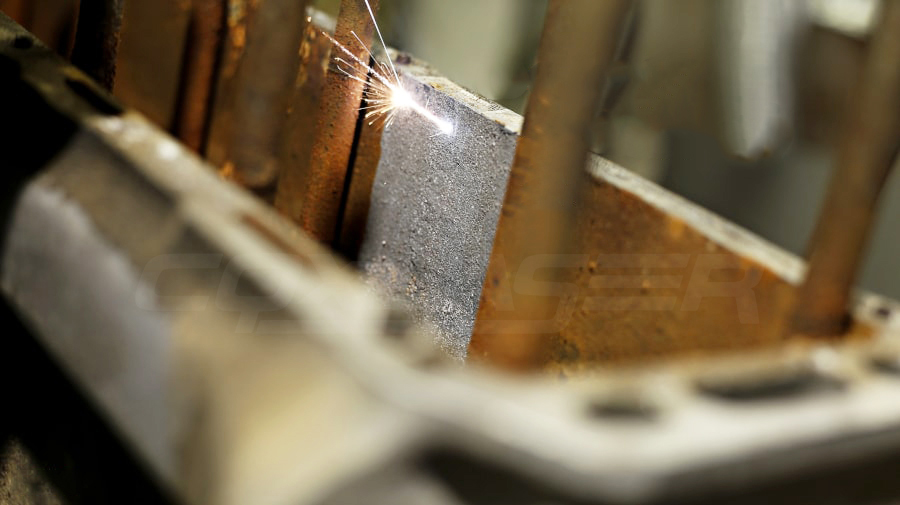

Picture this: A billboard frame, meticulously welded with unparalleled precision, ready to withstand the elements for years to come. Or consider a rusted metal sign restored to its original luster in mere moments, without any harmful chemicals or abrasive processes. This is the power of laser welding equipment and rust cleaning lasers—two groundbreaking technologies that are transforming the production process in the advertising world.

In this article, we explore the diverse applications of these laser technologies in the advertising industry and how they are reshaping how advertisements are designed, built, and maintained. From custom sign fabrication to large-scale outdoor advertising installations, laser welding equipment and rust cleaning lasers provide solutions that increase efficiency, enhance precision, and reduce environmental impact.

1.Laser Welding Equipment: Precision and Durability in Advertising Sign Manufacturing

Laser welding equipment is an essential tool for manufacturers in the advertising industry. This technology is particularly effective for creating strong, durable joints between metal components used in sign production, display frames, and other advertising structures.

How Laser Welding Works in Advertising

Unlike traditional welding methods, which can be imprecise and generate excess heat, laser welding equipment uses a concentrated laser beam to melt and fuse metal parts with extreme accuracy. The laser’s high energy density allows it to penetrate metal surfaces deeply, ensuring that the joint is strong and durable without affecting the surrounding material. This makes laser welding ideal for creating intricate, high-quality metal signs and frames that require both precision and strength.

In the advertising industry, laser welding is particularly useful when dealing with materials like stainless steel, aluminum, and brass—common metals used in outdoor signs, display boards, and billboards. The technology enables manufacturers to join metal components with minimal distortion, resulting in smoother surfaces and aesthetically pleasing seams. Whether it’s for creating custom logo designs or assembling large-scale advertising structures, laser welding equipment offers superior results compared to conventional welding methods.

Advantages for Advertising Manufacturers

For advertising manufacturers, the benefits of laser welding equipment are significant. The precision provided by laser welding ensures that each joint is made with the utmost accuracy, which is essential when creating large signs or displays that must withstand outdoor elements such as wind, rain, and sunlight.

In addition to its precision, laser welding is faster than traditional welding methods, allowing for quicker production times. This speed can reduce labor costs and increase overall efficiency. Furthermore, because laser welding produces less heat, it minimizes the risk of warping or damaging delicate parts, making it a safe and reliable choice for creating intricate sign designs.

Sustainability and Cost-Efficiency

Another important advantage of laser welding in the advertising industry is its cost-efficiency and environmental sustainability. The process uses less energy than traditional welding techniques and produces minimal waste, which helps reduce the carbon footprint of manufacturing operations. By minimizing the need for post-welding cleaning or finishing, laser welding equipment can further reduce operational costs and improve production turnaround times.

2.Rust Cleaning Laser: Restoring and Maintaining Advertising Materials

Outdoor advertising materials, especially metal signs and frames, are constantly exposed to harsh environmental conditions, including moisture, dust, and pollution. Over time, this exposure can cause rust and corrosion, which can damage the materials and negatively impact the visual appeal of the advertisement. Enter rust cleaning lasers—a powerful and environmentally friendly solution for removing rust, dirt, and other contaminants from metal surfaces without causing damage.

How Rust Cleaning Lasers Work

Rust cleaning lasers operate by directing a high-energy laser beam at a rusted or contaminated metal surface. The laser heats the rust or oxide layer rapidly, causing it to evaporate or be blown away by the pressure of the laser beam. This results in a clean, smooth surface free from rust, paint, or other contaminants, leaving the underlying metal intact and unscathed.

For the advertising industry, rust cleaning lasers provide an efficient and precise method for restoring signs, frames, and other metal components. Instead of using abrasive methods, such as sandblasting, which can scratch or damage the surface, rust cleaning lasers gently remove rust and contaminants, ensuring that the metal remains undamaged and ready for further processing, such as welding or coating.

Benefits for Advertising Companies

One of the key benefits of rust cleaning lasers in the advertising industry is their ability to restore aging metal signs to their original condition quickly and effectively. With outdoor advertising structures often exposed to the elements for years, rust and corrosion can become a major issue. Rust cleaning lasers can remove these imperfections without the need for harsh chemicals, making the process safer and more environmentally friendly than traditional methods.

Moreover, laser rust cleaning is a dry process, meaning it does not produce wastewater or chemical runoff. This makes it an eco-friendly solution, aligning with the increasing demand for sustainable practices in the manufacturing and maintenance of advertising materials.

Additionally, rust cleaning lasers are incredibly precise, meaning they can be used on delicate or intricate designs without causing damage to the surrounding area. This precision is particularly important when restoring custom signs or frames, ensuring that the final product looks as good as new.

Increasing Durability and Longevity

By regularly using rust cleaning lasers to maintain outdoor signage, advertising companies can significantly extend the lifespan of their materials. The ability to remove rust and contaminants prevents further degradation of the metal, ensuring that signs remain structurally sound and visually appealing for years to come. This maintenance process not only reduces the need for frequent replacements but also contributes to the overall sustainability of advertising operations.

3.The Synergy of Laser Welding and Rust Cleaning in Advertising Production

When combined, laser welding equipment and rust cleaning lasers provide a powerful, integrated solution for creating and maintaining advertising materials. By using laser welding for the precise fabrication of metal components and rust cleaning lasers for effective surface preparation and maintenance, advertising companies can improve both the production quality and longevity of their signage and structures.

Streamlining the Production Process

In the production of large-scale advertising displays, such as billboards or digital signage frames, both laser welding and rust cleaning lasers play critical roles in ensuring the final product is durable and high-quality. After the metal components are welded together with laser welding equipment, rust cleaning lasers can be used to remove any surface contaminants, ensuring that the components are ready for coating, painting, or other finishing processes.

This streamlined process not only saves time and reduces costs but also ensures that each piece of advertising infrastructure is built to last. The precision offered by laser welding minimizes the need for post-production adjustments, while laser rust cleaning helps maintain the aesthetic integrity and structural strength of the materials.

Ensuring Long-Term Performance and Sustainability

The combination of laser welding and rust cleaning lasers enables advertising companies to produce high-performance materials that can endure the test of time, particularly in outdoor environments where weather and pollution can take a toll on signage. These technologies work in tandem to ensure that advertisements remain pristine, functional, and environmentally friendly, aligning with the growing demand for sustainable and durable advertising solutions.

By adopting these advanced technologies, advertising companies can meet the industry’s increasing expectations for quality, efficiency, and environmental responsibility, all while reducing costs and improving productivity.

4.Future Prospects of Laser Technology in Advertising

As the advertising industry continues to evolve, the use of laser welding equipment and rust cleaning lasers is expected to grow, driven by the demand for higher-quality, more sustainable, and customizable advertising materials. The ability to create complex, durable designs with minimal environmental impact will become increasingly important, and laser technology is well-positioned to meet these demands.

CQX LASER is at the forefront of this innovation, providing cutting-edge laser solutions that are shaping the future of advertising production. As technology advances, the potential applications of laser welding and rust cleaning lasers in the advertising industry will continue to expand, opening new possibilities for design, manufacturing, and maintenance.

By embracing these technologies, advertising companies can not only improve their bottom line but also contribute to the broader goals of sustainability and innovation in the global market. The future of advertising lies in the precision and efficiency of laser technology, offering endless possibilities for the industry to explore.

Incorporating laser welding equipment and rust cleaning lasers into the production and maintenance of advertising materials is a strategic move for companies seeking to improve efficiency, quality, and sustainability. These advanced technologies are not just enhancing the current advertising landscape; they are redefining it. The future of advertising is laser-focused, and the possibilities are limitless.