Handheld Laser Welding Machine: Redefining Precision and Efficiency in Modern Manufacturing

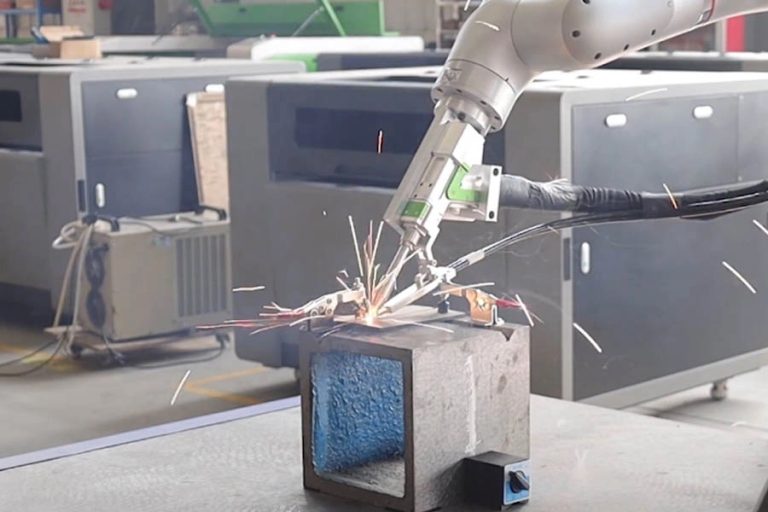

The handheld laser welding machine has become a cornerstone of innovation, transforming how industries approach precision, speed, and quality in welding tasks. Imagine a tool that merges the finesse of manual craftsmanship with the efficiency of cutting-edge technology—the handheld laser welding machine is exactly that. Its ability to adapt to diverse applications makes it an essential device across various industries, revolutionizing workflows with its unmatched versatility. With CQX leading the way, this innovation is set to shape the future of welding like never before.

Introduction to Handheld Laser Welding Machines

A handheld laser welding machine represents the pinnacle of technological advancement in the welding industry. These devices, powered by high-energy laser technology, bring unparalleled flexibility and precision to tasks that were once cumbersome and time-intensive.

From intricate jewelry repairs to robust industrial applications, handheld laser welders are becoming the go-to solution for welding needs.

Laser welding technology has been a staple in aerospace and automotive industries for decades, but the portability and user-friendliness of handheld devices have opened doors to broader applications. This innovation eliminates the need for bulky setups, allowing operators to achieve precise welds without sacrificing mobility or speed.

How Handheld Laser Welding Machines Work

Handheld laser welding machines rely on concentrated beams of high-energy light to fuse materials. The process is both simple and effective, offering a level of precision that traditional methods cannot match. Here’s an in-depth look at how these machines operate:

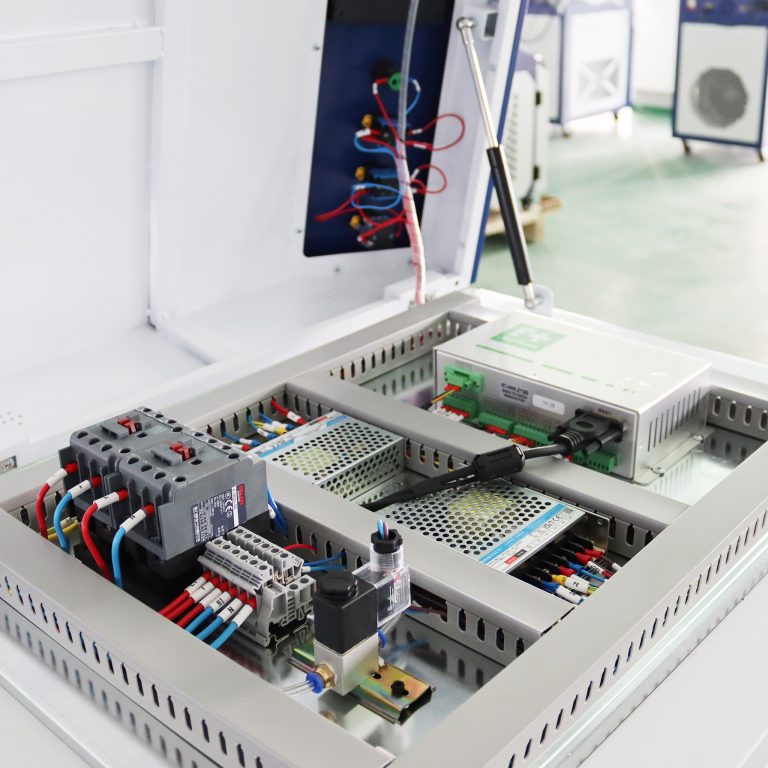

1.Core Components

• Laser Source:Typically a fiber laser, known for its efficiency and excellent beam quality.

• Beam Delivery System: Ensures the laser’s energy is directed accurately onto the welding surface.

• Cooling System: Maintains the machine’s temperature during prolonged use, ensuring reliability.

• Safety Mechanisms: Incorporates shields, sensors, and interlocks to protect users.

2.Operational Mechanism

The laser beam generates heat at a localized point, melting the material’s surface and creating a seamless bond as it cools.

This method minimizes heat-affected zones and delivers:

• High-strength welds

• Superior precision

• Minimal material distortion

Applications Across Industries

Handheld laser welding machines find applications in a wide range of industries due to their adaptability and efficiency. These machines excel in both large-scale industrial projects and fine, detailed work.

1.Automotive Industry

• Welding intricate components like exhaust systems and batteries

• Quick repairs without disassembling parts

• Enhanced production efficiency with minimal downtime

2.Aerospace Applications

• Joining lightweight, high-performance alloys

• Precision repairs of aircraft components

• Ensuring reliability in critical systems

3.Electronics Manufacturing

• Fine welding for delicate electronic components

• Minimal thermal damage to sensitive parts

4.Medical Equipment

• Biocompatible welding for surgical instruments and implants

• Ensuring hygienic and precise results

5.Jewelry and Craftsmanship

• Repairing and creating intricate designs

• Achieving flawless results with minimal effort

Benefits of Handheld Laser Welding Machines

Handheld laser welding machines offer numerous advantages that make them indispensable in modern manufacturing. Key benefits include:

1.Unmatched Precision

Laser technology enables extremely precise welds, crucial for applications requiring tight tolerances.

2.Portability and Ease of Use

The ergonomic design of handheld devices allows operators to maneuver them in challenging spaces.

3.Reduced Costs

By optimizing material usage and reducing waste, these machines lower operational costs significantly.

4.Minimal Heat Impact

The focused laser beam limits heat-affected zones, preserving the integrity of surrounding materials.

Key Features of Advanced Handheld Laser Welders

Selecting the right handheld laser welding machine requires attention to its features. Look for:

• Adjustable Settings: Customizable power levels for different materials

• Ergonomic Design: Ensures operator comfort during extended use

• Durable Build: Long-lasting components suitable for industrial applications

• Advanced Safety: Long-lasting components suitable for industrial applications

Innovations Driving the Technology

1.Advances in Beam Control

Improved focus and precision make handheld laser welding machines suitable for even the most intricate tasks.

2.AI Integration

Artificial intelligence enhances efficiency by automating adjustments for optimal welding results.

3.IoT Connectivity

Internet of Things integration enables real-time monitoring and diagnostics, improving machine reliability.

Maintenance Tips for Longevity

To maximize the lifespan and efficiency of handheld laser welding machines, regular maintenance is essential:

• Clean the Optics: Prevent debris buildup that can affect performance.

• Check Cooling Systems: Ensure proper function to avoid overheating.

• Inspect Safety Features: Regularly test shields and sensors for optimal operation.

Selecting the Right Machine

Finding the ideal handheld laser welding machine depends on your specific requirements. Consider:

• Material Compatibility: Ensure the machine can handle your materials and applications.

• Customization Options: Look for models that offer adjustable settings and modular designs.

• Durability: Choose a machine built for long-term use and consistent performance.

Real-World Success Stories

1.Automotive Efficiency Boost

An automotive supplier reduced repair times by 40% using handheld laser welders for on-site fixes.

2.Artisan Jewelry Transformation

A jewelry designer expanded their product line with intricate designs made possible by handheld laser welding technology.

The Road Ahead: The Future of Handheld Laser Welding Machines

Handheld laser welding machines are paving the way for smarter, more sustainable manufacturing processes. With innovations such as AI and IoT integration, they promise to enhance efficiency while reducing environmental impact. As industries evolve, the versatility and reliability of these devices will continue to make them indispensable.