Handheld Rust Cleaning Laser: Revolutionizing Surface Restoration

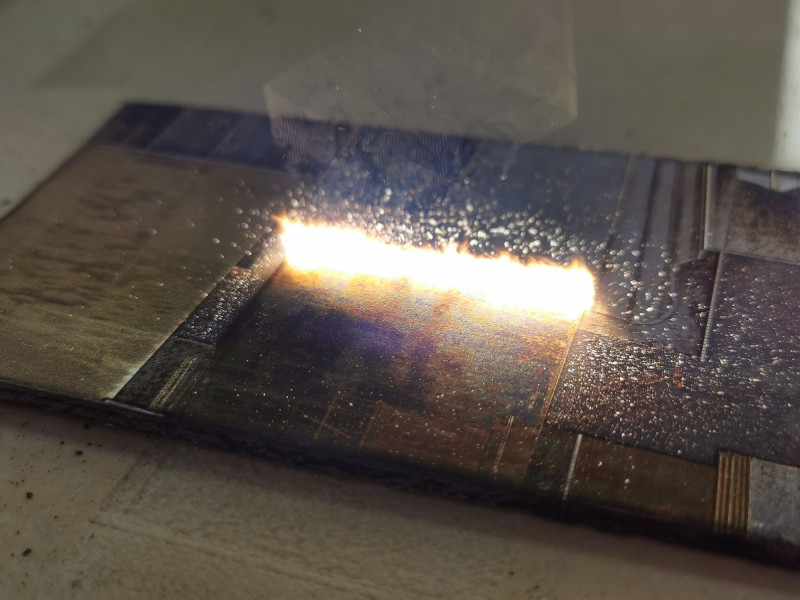

The handheld rust cleaning laser is transforming the world of surface cleaning, offering unparalleled precision, speed, and efficiency. Imagine a tool that effortlessly erases years of corrosion, revealing pristine surfaces without damaging the base material. This technology is not just a tool; it’s a revolution—a fusion of science and practicality that replaces abrasive methods with laser precision. With CQX leading the charge, the handheld laser has become a cornerstone in rust removal, unlocking new levels of efficiency across industries.

Introduction to Handheld Rust Cleaning Lasers

A handheld rust cleaning laser is an advanced tool that utilizes high-powered laser beams to remove rust, paint, and other surface contaminants. Unlike traditional methods, such as sandblasting or chemical treatments, lasers provide a contactless, eco-friendly solution that minimizes waste and maximizes results.

This innovative technology has gained traction across various sectors, including automotive, aerospace, and heritage conservation, due to its adaptability and precision. By offering an alternative to traditional, labor-intensive methods, handheld laser cleaners enable industries to save time and resources while achieving superior results.

How Does a Handheld Rust Cleaning Laser Work?

Handheld laser welding machines rely on concentrated beams of high-energy light to fuse materials. The process is both simple and effective, offering a level of precision that traditional methods cannot match. Here’s an in-depth look at how these machines operate:

1.Key Components

• Laser Source:Typically a fiber laser known for its efficiency and durability.

• Beam Delivery System: Ensures precise targeting of the laser beam.

• Control Panel: Allows operators to adjust settings for different applications.

• Cooling System: Maintains optimal operating temperature for consistent performance.

2.The Mechanism

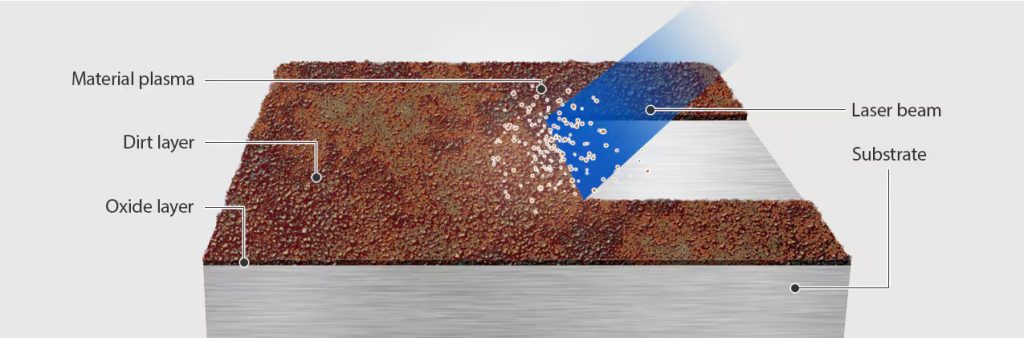

The laser’s energy interacts with the rust layer, causing it to break down into vaporized particles that are then easily removed. The process involves:

• Absorption of laser energy by contaminants

• Rapid heating and thermal decomposition

• No impact on the underlying surface

Applications of Handheld Rust Cleaning Lasers

The versatility of handheld rust cleaning lasers makes them indispensable across a range of industries:

1.Automotive Restoration

• Cleaning corroded car parts

• Removing old paint layers for refinishing

• Enhancing efficiency in part refurbishment

2.Aerospace Maintenance

• Removing corrosion from aircraft components

• Cleaning sensitive surfaces with precision

• Ensuring compliance with strict safety standards

3.Industrial Equipment Maintenance

• Restoring machinery surfaces

• Removing grease, oil, and rust from parts

• Reducing downtime during maintenance cycles

4.Heritage Conservation

• Cleaning historical monuments without damaging delicate materials

• Preserving intricate details in sculptures and artifacts

• Using non-invasive methods to protect cultural heritage

5.Manufacturing and Fabrication

• Preparing surfaces for welding and bonding

• Cleaning molds and tools in production lines

• Ensuring high-quality finishes

Benefits of Handheld Rust Cleaning Lasers

Handheld rust cleaning lasers offer numerous advantages over traditional methods:

1.Eco-Friendly and Non-Toxic

Unlike chemical treatments, laser cleaning does not produce harmful waste, making it an environmentally responsible choice.

2.Precision Cleaning

The targeted laser beam ensures precise rust removal, preserving the integrity of the underlying material.

3.Minimal Maintenance

With no abrasive media or chemicals involved, laser cleaning systems require less upkeep and provide long-term reliability.

4.Enhanced Safety

Contactless operation reduces the risk of injury, while built-in safety features protect operators during use.

5.Cost-Efficiency

By reducing material waste and labor costs, laser cleaning systems provide a cost-effective solution for industrial and commercial applications.

Key Features of Advanced Handheld Rust Cleaning Lasers

Choosing the right handheld rust cleaning laser involves understanding its key features. Look for:

• Adjustable Power Settings: Tailor the laser’s intensity for different materials and rust levels.

• Portable Design: Ensure ease of use in various working environments.

• Durability: Opt for machines designed to withstand heavy-duty operations.

• Safety Features: Consider devices with automatic shutdown and interlocks.

Innovations in Laser Cleaning Technology

1.High-Powered Fiber Lasers

Advancements in fiber laser technology have made handheld devices more efficient and reliable than ever before.

2.Integration with Automation

Some systems now include robotic arms or AI algorithms for automated cleaning in large-scale operations.

3.Enhanced Cooling Systems

Innovative cooling mechanisms ensure consistent performance during prolonged use.

4.Real-Time Monitoring

IoT-enabled devices allow operators to track performance and make adjustments remotely, enhancing productivity.

Maintenance and Care Tips

Proper maintenance ensures optimal performance and longevity of handheld rust cleaning lasers:

• Regular Cleaning: Remove debris from the lens and optical components.

• Cooling System Checks: Ensure the system is functioning correctly to avoid overheating.

• Routine Calibration: Maintain accuracy by periodically calibrating the device.

• Safety Inspections: Test safety features regularly to ensure compliance with operational standards.

Selecting the Right Handheld Laser

When selecting a handheld rust cleaning laser, consider the following:

• Application Requirements: Choose a device with appropriate power and features for your specific needs.

• Portability: Opt for lightweight, compact models for ease of use.

• Durability: Ensure the device can withstand rigorous use

• Customizable Options: Look for machines with adjustable settings to handle various tasks.

Success Stories: Real-World Applications

1.Industrial Equipment Revitalization

A manufacturing company reduced maintenance costs by 30% using handheld lasers for rust removal and surface preparation.

2.Automotive Restoration Excellence

An automotive workshop achieved flawless results in restoring vintage car parts, enhancing customer satisfaction.

3.Cultural Heritage Preservation

A museum utilized handheld laser technology to clean centuries-old sculptures without damaging the intricate details.

The Future of Handheld Rust Cleaning Lasers

The handheld rust cleaning laser is set to play a pivotal role in future industrial and conservation efforts. With continued advancements in laser technology and integration with AI and IoT, these devices will become more efficient and accessible. As industries embrace sustainable practices, the eco-friendly and precise nature of laser cleaning will ensure its place as a preferred solution for surface restoration.