Welding Laser Machine Price: What You Need to Know

The price of a welding laser machine often sparks questions from businesses aiming to improve their production processes. Is it worth the investment? What factors drive the cost? Whether you’re considering an entry-level model or a fully automated system, understanding welding laser machine prices will help you make an informed decision.

In this comprehensive guide, we’ll break down the key factors affecting costs, typical price ranges, and expert tips for choosing the best welding laser machine for your applications.

1. What is a Welding Laser Machine?

A welding laser machine uses a concentrated beam of light to fuse metal or plastic components. This advanced technology offers unmatched precision, speed, and minimal post-weld processing compared to traditional welding methods.

2. Factors That Affect Welding Laser Machine Price

The price of a welding laser machine depends on several key elements:

2.1 Power Output

Measured in watts, the laser’s power level determines its ability to handle different materials and thicknesses.

• Low Power (100W – 500W):Ideal for thin materials and detailed work.

• Mid-Power (500W – 1,500W):Suitable for general industrial applications.

• High Power (2,000W+):Designed for thick materials and large-scale production.

2.2 Laser Type

Different types of lasers influence the machine’s price:

• Fiber Lasers:Known for high efficiency and low maintenance but come at a premium cost.

• CO₂ Lasers:More affordable but better suited for non-metal materials.

• Solid-State Lasers:Versatile but often more expensive due to their precision and durability.

2.3 Automation Level

Manual, semi-automated, and fully automated systems have different price ranges:

• Manual Machines:$8,000 – $20,000

• Semi-Automated Systems:$20,000 – $50,000

• Fully Automated Systems:$50,000 – $500,000+

2.4 Cooling System

Efficient cooling systems (air or water-based) prevent overheating and prolong machine lifespan. High-performance water-cooled systems can increase costs.

2.5 Accessories and Add-Ons

Additional features such as custom nozzles, protective enclosures, and software upgrades can significantly affect the overall price.

3. Typical Price Ranges for Welding Laser Machines

To give you a clearer idea of what to expect, here’s a breakdown of common price ranges:

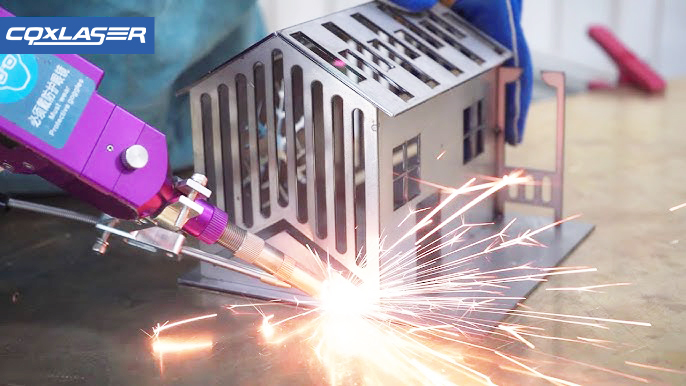

• Entry-Level Handheld Models:$8,000 – $15,000

° Ideal for small workshops and field repairs.

• Mid-Range Desktop Units: $15,000 – $50,000

° Best for precision welding tasks like jewelry and electronics.

• Industrial-Grade Systems: $50,000 – $300,000+

° Suitable for high-speed production lines and heavy-duty applications.

4. Comparing Welding Laser Machine Prices by Application

| Application | Recommended Power | Typical Price Range |

|---|---|---|

| Automotive Frames | 1,500W – 3,000W | $50,000 – $250,000+ |

| Aerospace Components | 2,000W – 6,000W | $100,000 – $500,000+ |

| Medical Devices | 500W – 1,000W | $20,000 – $80,000 |

| Electronics Assembly | 300W – 800W | $10,000 – $50,000 |

| Jewelry Repair | 100W – 200W | $8,000 – $20,000 |

5. Benefits of Investing in a Welding Laser Machine

5.1 High Precision and Accuracy

Laser welding produces clean, precise joints with minimal material distortion, reducing post-weld work.

5.2 Faster Production Times

Laser machines complete welds significantly faster than traditional methods, boosting productivity.

5.3 Cost-Effective Over Time

Although the initial investment may be high, the long-term savings in labor, material waste, and maintenance make it cost-effective.

5.4 Versatility

A welding laser machine can handle various materials, including stainless steel, aluminum, copper, and more.

6. Key Features to Consider When Choosing a Welding Laser Machine

6.1 Power and Speed Settings

Select a machine with adjustable power and speed settings for greater flexibility across different materials.

6.2 Cooling System

Ensure the machine has an efficient cooling system to prevent overheating and prolong its lifespan.

6.3 Software Interface

User-friendly software with programmable presets enhances operational efficiency and precision.

6.4 Safety Features

Look for features such as protective shields, emergency shut-off buttons, and fume extraction systems.

7. Financing and Leasing Options

Many suppliers offer financing plans to help businesses manage the upfront cost of a welding laser machine. Common options include:

• Installment Payments:Spread the cost over a fixed period.

• Leasing Agreements:Pay a monthly fee to use the machine without owning it outright.

• Trade-In Programs:Reduce costs by trading in older equipment.

8. Safety Considerations for Welding Laser Machines

Operating a welding laser machine requires strict safety protocols:

1. Wear Protective Gear:Use laser-rated goggles to prevent eye damage.

2. Ensure Proper Ventilation:Keep the workspace ventilated to remove welding fumes.

3. Enclose the Work Area:Use protective barriers to shield operators from stray beams.

4. Regularly Inspect Cooling Systems:Ensure the cooling system is functioning correctly to prevent overheating.

9. Innovations in Welding Laser Machine Technology

9.1 AI-Powered Welding Systems

Artificial intelligence systems automatically adjust welding parameters for optimal results.

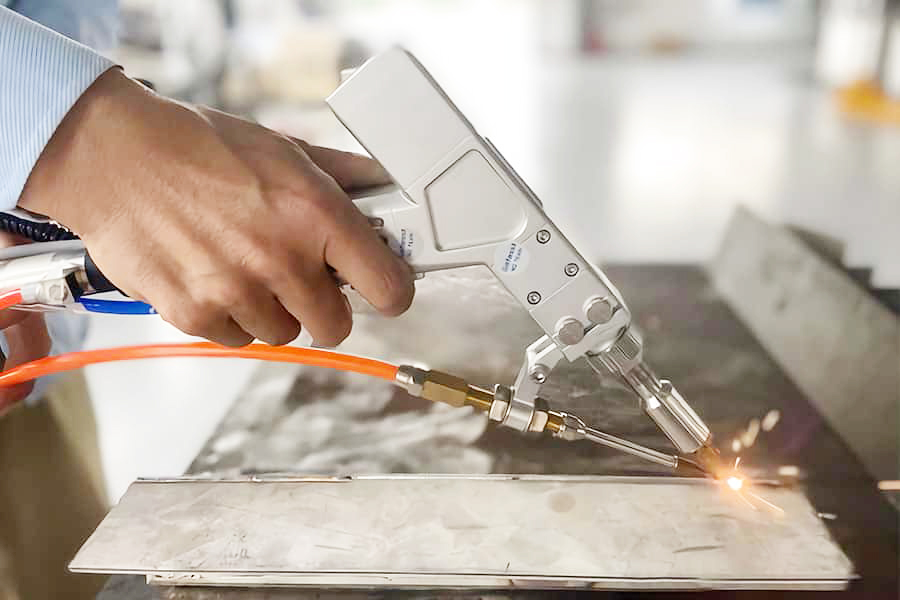

9.2 Portable Laser Welders

Compact, battery-operated units offer enhanced mobility for fieldwork and remote repairs.

9.3 Green Laser Technology

Energy-efficient lasers reduce power consumption and minimize environmental impact.

10. Frequently Asked Questions About Welding Laser Machine Prices

Q: Why are industrial-grade laser machines so expensive?

A: They feature higher power levels, automation capabilities, and robust designs for continuous operation, which increases the cost.

Q: Can I lease a welding laser machine instead of buying one?

A: Yes, many suppliers offer leasing agreements that allow businesses to use the equipment for a monthly fee.

Q: What is the lifespan of a welding laser machine?

A: With proper maintenance, a high-quality welding laser machine can last 10 to 15 years or more.

By understanding the factors that influence welding laser machine prices and evaluating your specific needs, you can make an informed purchase that balances cost with performance. Whether you’re upgrading your production line or starting a new project, the right machine will provide long-term value, improved efficiency, and superior weld quality.