Rust Cleaner Laser: Your Ultimate Surface Restoration Solution

When it comes to surface cleaning, few tools are as effective as a rust cleaner laser. Imagine a cleaning method so precise that it removes rust, paint, and dirt in seconds without damaging the base material. No messy chemicals, no abrasive blasting—just pure laser energy transforming rusty surfaces back to their original glory. Whether you’re restoring automotive parts or maintaining industrial equipment, laser cleaning technology is setting a new standard for efficiency and performance.

What Is a Rust Cleaner Laser?

A rust cleaner laser is a high-tech device that uses focused laser pulses to remove surface contaminants like rust and corrosion. This process, called laser ablation, heats and vaporizes the rust layer without harming the metal underneath.

Unlike traditional methods such as sanding or chemical stripping, laser cleaning is non-contact, eco-friendly, and produces minimal waste.

How a Rust Cleaner Laser Works

1. Laser Beam Emission: The device emits high-energy laser pulses toward the rusted surface.

2. Absorption and Reaction: The rust absorbs the energy, heats up, and breaks apart.

3. Vaporization: The rust particles turn into gas or dust, leaving behind a clean surface.

This method is highly precise, allowing users to adjust settings to clean delicate surfaces or remove thick layers of rust quickly.

Benefits of Using a Rust Cleaner Laser

1. Eco-Friendly and Chemical-Free

Laser cleaning eliminates the need for harmful solvents, making it a safer and greener solution.

2. Non-Abrasive Cleaning

Unlike sandblasting or grinding, laser cleaning preserves the surface’s integrity, avoiding scratches or weakening of the material.

3. Precision and Control

Adjustable power settings allow users to clean specific areas without damaging surrounding surfaces.

4. Cost-Effective Solution

Although the initial investment may be high, a rust cleaner laser reduces ongoing costs related to consumables, labor, and maintenance.

5. Versatility and Portability

Many rust cleaner lasers are portable, allowing operators to perform on-site cleaning tasks efficiently.

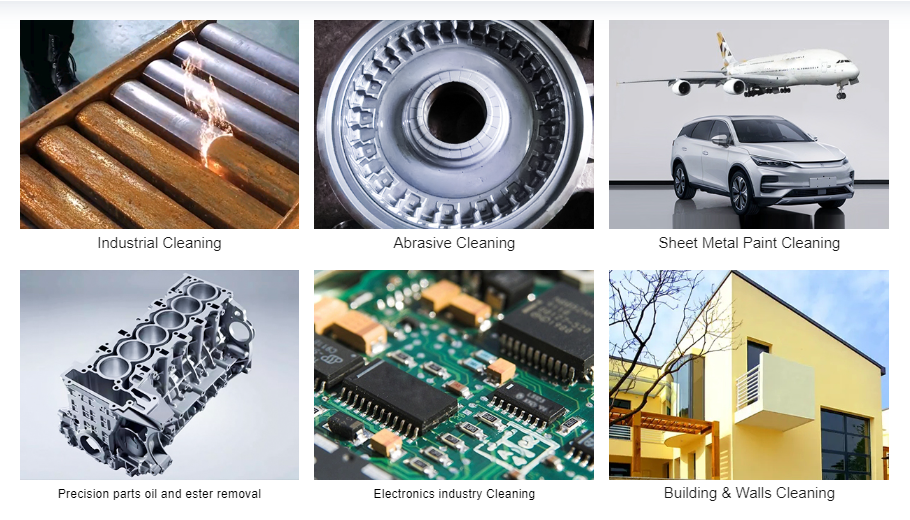

Common Applications for Rust Cleaner Lasers

1. Automotive Restoration

These lasers remove rust, paint, and grime from car frames, engine parts, and suspension components, preparing them for repainting or repair.

2. Aerospace and Aviation

Aircraft components require precision cleaning to maintain performance and safety standards. Rust cleaner lasers remove oxidation without damaging the underlying metal.

3. Industrial Maintenance

Factories use laser cleaners to maintain production equipment, such as molds, conveyor belts, and machine parts, reducing downtime and improving efficiency.

4. Shipbuilding and Marine Repairs

Portable rust cleaner lasers effectively remove corrosion, salt deposits, and barnacles from ship hulls, decks, and offshore platforms.

5. Cultural Heritage Preservation

Museums and conservators use laser cleaners to safely remove grime and pollutants from historical artifacts and sculptures without damaging the original surface.

Types of Rust Cleaner Lasers

1. Low-Power Lasers (50W - 100W)

These models are designed for light cleaning tasks, such as removing surface rust or soot from small metal parts.

2. Mid-Power Lasers (200W - 500W)

Perfect for industrial use, these machines provide a balance of power and precision for most surface cleaning applications.

3. High-Power Lasers (1000W and Above)

Built for heavy-duty cleaning, these lasers can strip thick rust, coatings, and paint layers from large surfaces in minimal time.

Key Features to Consider When Choosing a Rust Cleaner Laser

1. Power Output

The power level determines how quickly and effectively the laser can clean a surface.

2. Cooling System

Air-cooled lasers are lighter and more affordable, while water-cooled systems provide better thermal management for extended use.

3. Portability and Design

Look for a compact, lightweight model with ergonomic handles if you need to perform on-site cleaning tasks.

4. Safety Features

Ensure the machine includes essential safety measures, such as emergency stop buttons, protective goggles, and automatic shut-off systems.

5. User-Friendly Interface

A touchscreen interface with pre-set cleaning modes can simplify the operation and improve accuracy.

Price Ranges for Rust Cleaner Lasers

The cost of a rust cleaner laser varies depending on its specifications and features. Here’s a general breakdown:

• Entry-Level Models (50W – 100W): $8,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-End Models (1000W and Above): $50,000+

Additional costs may include shipping, installation, and optional accessories such as extra lenses or nozzles.

Maintenance Tips for Rust Cleaner Lasers

1. Regularly Clean the Lens: Keep the laser lens free from dust and debris to maintain accuracy and efficiency.

2. Inspect the Cooling System: Ensure the air or water cooling system is functioning properly and free of blockages.

3. Check the Fiber Cables: Damaged cables can reduce laser performance and should be replaced as needed.

4. Follow Usage Guidelines: Adhere to the manufacturer’s recommendations for operation times to prevent overheating.

5. Store Safely: When not in use, store the machine in a dry, dust-free environment to prolong its lifespan.

Innovations in Rust Cleaner Laser Technology

Modern rust cleaner lasers feature AI-driven adjustments that automatically optimize laser intensity based on the surface type and contaminant thickness. Green laser technology is also being developed to improve cleaning on non-metal surfaces, making the machines even more versatile.

Comparing Laser Cleaning to Traditional Methods

1. Efficiency

Laser cleaning significantly reduces the time required for surface preparation compared to manual scraping or chemical treatments.

2. Cost Savings

Although laser cleaning machines require an initial investment, the long-term savings on consumables and labor costs make them a worthwhile investment.

3. Environmental Impact

Laser cleaning produces no chemical waste or harmful residues, making it an eco-friendly alternative to traditional methods.

4. Precision and Control

Unlike abrasive blasting, lasers can target specific areas with pinpoint accuracy, making them ideal for detailed restoration work.

Choosing the Right Rust Cleaner Laser for Your Needs

When selecting a rust cleaner laser, consider the following:

• Type of Surface: Is the surface metal, stone, or another material?

• Frequency of Use: Will the machine be used occasionally or for continuous industrial cleaning?

• Portability: Do you need a handheld unit for fieldwork or a stationary system for workshop use?

• Budget: Determine your budget, considering both the initial cost and maintenance expenses.

A rust cleaner laser is more than a tool—it’s a game-changing solution that enhances productivity, precision, and sustainability in surface cleaning. Whether you’re restoring vintage car parts, maintaining industrial machinery, or preserving cultural artifacts, this innovative technology offers unmatched performance and versatility. Understanding its features, price range, and applications helps you make an informed investment that meets your operational needs.