Portable Laser Welder: Precision Meets Mobility

In the world of welding, precision, speed, and convenience have always been priorities. Enter the portable laser welder—a game-changing tool that offers unmatched flexibility without compromising performance. Imagine a welder that you can carry to any location, delivering clean, accurate welds with minimal setup. This technology is not just about convenience; it’s about elevating efficiency and broadening possibilities.

This comprehensive guide will take you through everything you need to know about portable laser welders, including how they work, their pricing, key features to consider, and how they compare to traditional methods.

1. What is a Portable Laser Welder?

A portable laser welder is a compact, mobile device designed for precision laser welding tasks. Unlike stationary or automated systems, these machines are lightweight, often handheld, and easy to transport, making them ideal for on-site repairs, small workshops, and remote projects.

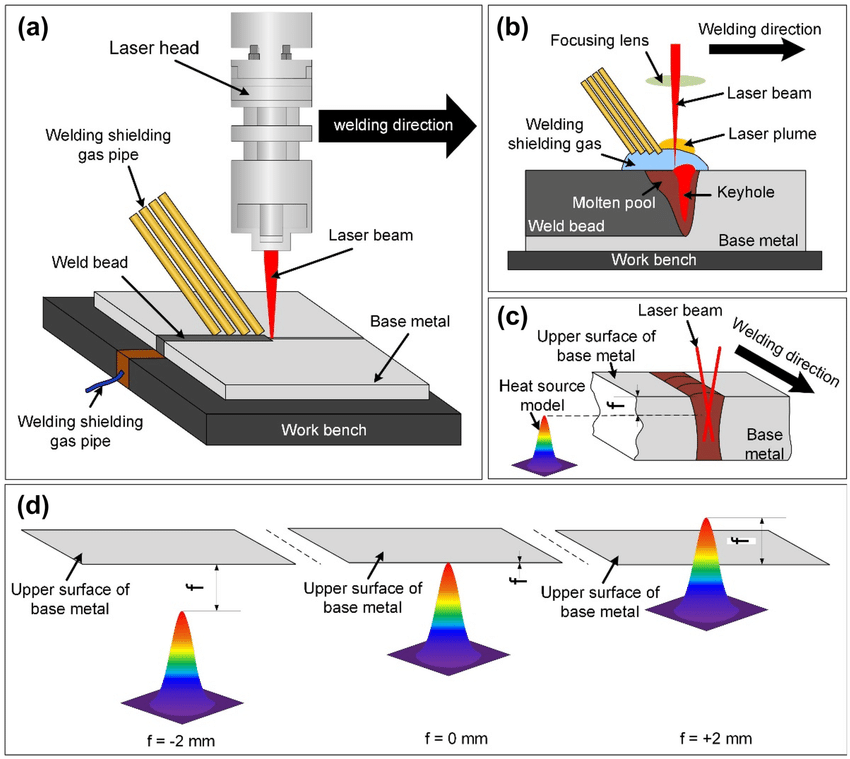

2. How Does a Portable Laser Welder Work?

The portable laser welder works by focusing a high-energy laser beam on the materials to be joined. The beam rapidly heats and melts the metal edges, creating a clean, precise bond. Some models come with an integrated wire feeder for applications that require filler material.

3. Key Features of a Portable Laser Welder

3.1 Power Output

Portable laser welders typically offer power outputs ranging from 500W to 2,000W. Higher wattage allows for deeper weld penetration and faster processing times.

3.2 Cooling Systems

Efficient cooling, often water-based, prevents overheating and allows for extended use without downtime.

3.3 User-Friendly Interfaces

Touchscreen controls and preset welding modes simplify operation, even for beginners.

3.4 Portability and Design

These machines are designed for easy transport, often equipped with ergonomic handles and lightweight frames.

4. Applications of Portable Laser Welders

Portable laser welders are used across various industries due to their versatility and convenience.

4.1 Automotive Repairs

Ideal for repairing vehicle frames, exhaust systems, and other metallic components.

4.2 Jewelry and Artisanal Work

Perfect for creating and repairing intricate metal designs.

4.3 Aerospace and Defense

Portable welders can handle high-precision tasks on-site without the need to disassemble large structures.

4.4 Construction and Metal Fabrication

Useful for joining beams, supports, and outdoor structures where transporting large equipment is impractical.

5. Advantages of Portable Laser Welders

5.1 Precision and Clean Welds

Laser welders produce smooth, uniform welds with minimal spatter and deformation.

5.2 Speed and Efficiency

These machines weld up to four times faster than traditional methods, significantly reducing project timelines.

5.3 Minimal Post-Weld Finishing

Laser welds require little to no post-processing, saving time and labor.

5.4 Portability

The portable design allows operators to bring the machine directly to the worksite, improving workflow and convenience.

6. Price Range of Portable Laser Welders

The cost of a portable laser welder varies based on features, power output, and additional accessories.

• Entry-Level Models (500W – 1,000W):$8,000 – $15,000

Suitable for small shops and hobbyist projects.

• Mid-Range Models (1,000W – 1,500W):$15,000 – $25,000

Designed for general industrial tasks.

• High-End Models (1,500W – 2,000W+):$25,000 – $40,000+

Ideal for large-scale, heavy-duty applications.

7. Factors Influencing the Cost of a Portable Laser Welder

7.1 Power and Wattage

Higher wattage machines can handle thicker materials and work faster but come at a premium price.

7.2 Build Quality and Durability

Machines with robust metal casings and high-quality internal components often have higher price tags but offer superior longevity.

7.3 Brand and Support

Some manufacturers offer extended warranties and 24/7 customer support, which can affect the overall cost.

7.4 Accessories and Add-Ons

Additional features such as a wire feeder, specialized nozzles, and protective lens kits may increase the initial cost.

8. Portable Laser Welder vs. Traditional Welding Methods

To understand the value of a laser welder, consider how it stacks up against conventional welding methods.

| Welding Method | Initial Cost | Speed | Precision | Post-Processing |

|---|---|---|---|---|

| TIG Welding | $2,000 - $10,000 | Moderate | High | Frequent |

| MIG Welding | $1,500 - $8,000 | Fast | Medium | Minimal |

| Laser Welding | $8,000 - $500,000 | Very Fast | Very High | Rare |

Portable laser welders offer unparalleled flexibility and precision, making them a superior choice for many tasks.

9. Safety Considerations

Although portable laser welders are user-friendly, safety precautions are essential to prevent injuries.

1.Wear laser-rated protective goggles to shield your eyes from high-intensity beams.

2.Ensure proper ventilation to avoid inhaling metal fumes.

3.Use heat-resistant gloves to prevent burns.

10. How to Choose the Right Portable Laser Welder

Selecting the right model requires careful consideration of your specific needs.

1.Identify Your Applications:Determine whether you need the welder for light repairs or heavy-duty projects.

2.Set a Budget:Establish a realistic budget that includes the cost of accessories and maintenance.

3.Evaluate Power Requirements:Choose a model with sufficient wattage for your typical workpieces.

4.Check After-Sales Support:Opt for manufacturers that offer strong customer support and warranties.

11. Emerging Trends in Portable Laser Welding

The portable laser welding market is evolving, with advancements that promise even greater efficiency:

• AI-Enhanced Controls:Automated settings that adjust welding parameters in real time for optimal performance.

• Battery-Powered Models:Development of cordless portable laser welders for maximum mobility.

• Compact Cooling Systems:Innovations in cooling technology that reduce the overall size and weight of the machine.

12. Financing Options

Many suppliers offer financing plans to help businesses manage the upfront cost of a portable laser welder.

Options include leasing, installment payments, and trade-in programs for older equipment.

13. Frequently Asked Questions

Q: Can portable laser welders handle thick metals?

A: Yes, high-power portable laser welders can handle metal sheets up to 10mm thick, depending on the material.

Q: Are they difficult to maintain?

A: Portable laser welders require minimal maintenance, with regular lens cleaning and occasional software updates.

Q: Is training required to operate a portable laser welder?

A: Basic training is recommended to maximize efficiency, but many models have user-friendly interfaces that simplify operation.

Portable laser welders are revolutionizing industries with their blend of precision, mobility, and speed.

By understanding their features, costs, and applications, you can make an informed choice that enhances your productivity and delivers exceptional results.