Portable Laser Cleaning Machine Price: Comprehensive Guide for Smart Buyers

The portable laser cleaning machine price often determines whether this cutting-edge tool fits your budget. Imagine owning a powerful yet portable device that removes rust, paint, and contaminants with ease. These machines deliver precision and convenience in surface cleaning, making them indispensable for industries and workshops. But how do you navigate the pricing landscape to make an informed purchase? This guide covers everything you need to know about costs, features, and value.

What Is a Portable Laser Cleaning Machine?

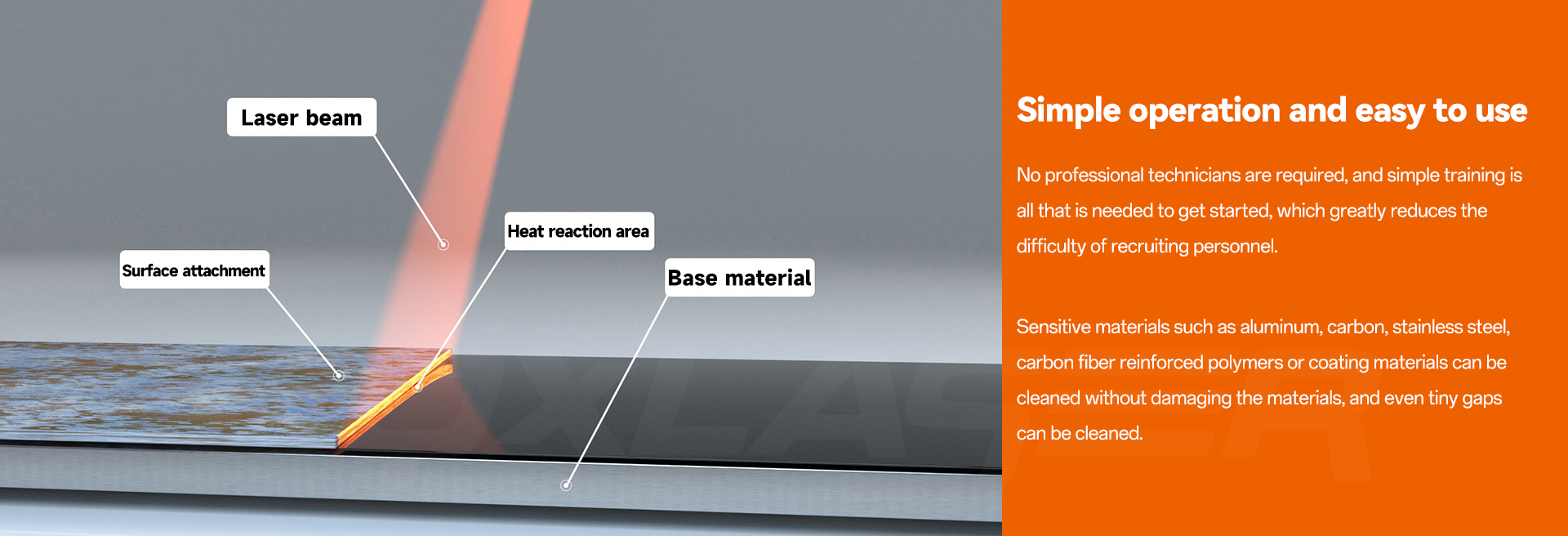

A portable laser cleaning machine uses high-energy laser beams to clean surfaces without abrasives or chemical agents. This process, called laser ablation, vaporizes contaminants such as rust, grease, and paint layers without damaging the base material.

The portable design ensures that users can clean items in various locations, whether in a factory, workshop, or outdoor setting.

How Does a Portable Laser Cleaning Machine Work?

1. Laser Pulse Generation: The machine emits concentrated pulses of light energy.

2. Contaminant Absorption: The unwanted surface material absorbs the energy and heats up.

3. Vaporization and Dusting: The contaminants disintegrate into gas or dust, leaving a clean surface behind.

This process is highly effective for precise and non-invasive cleaning, suitable for delicate items and heavy-duty applications alike.

Key Factors That Affect Portable Laser Cleaning Machine Prices

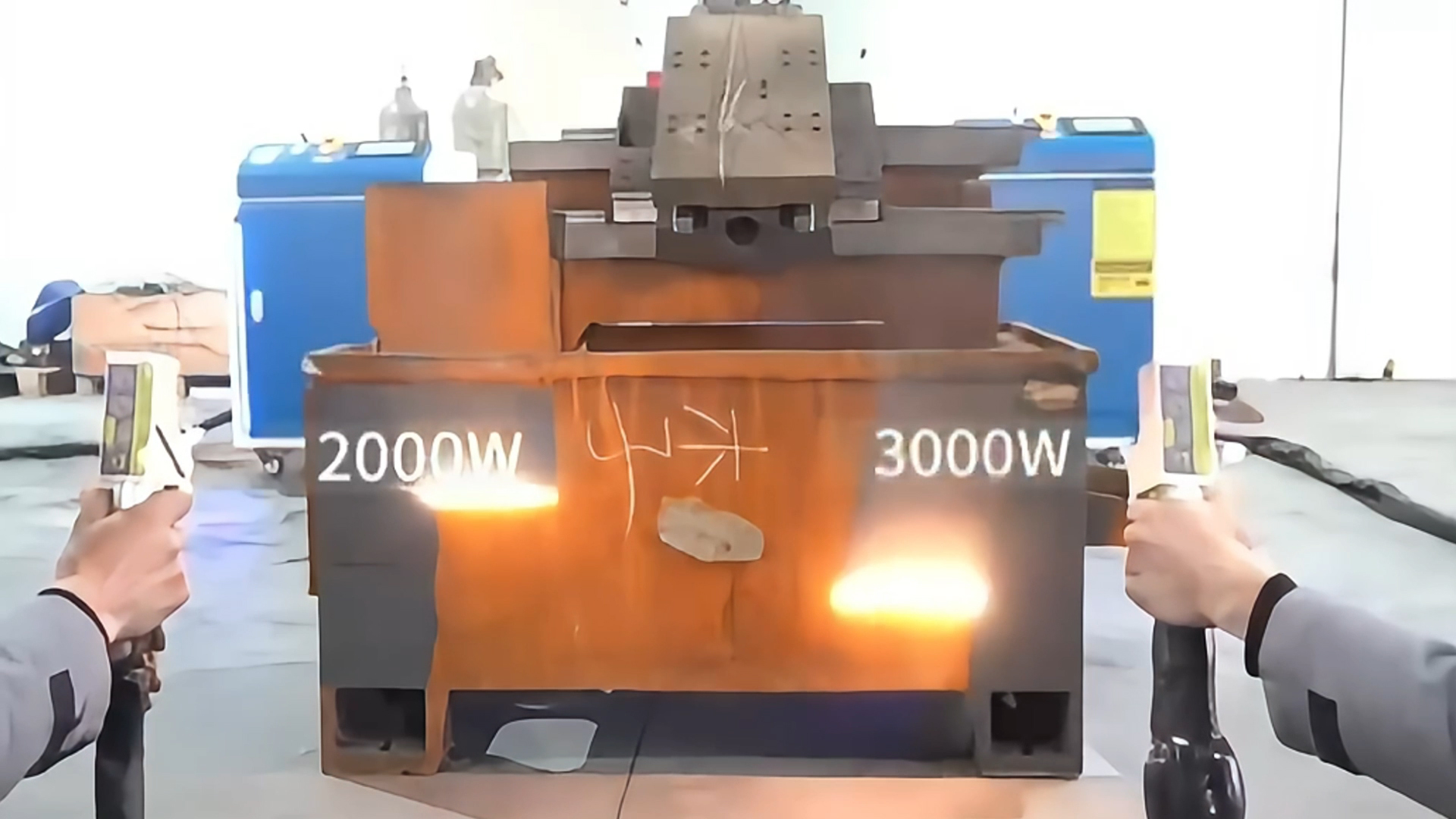

1. Power Output

The power rating of the machine directly impacts the price. Higher wattage models can remove thicker rust layers faster but come at a premium.

• Low-Power Units (50W – 100W): Suitable for light cleaning tasks such as surface rust removal.

• Mid-Power Units (200W – 500W): Ideal for general industrial cleaning.

• High-Power Units (1000W and Above): Designed for intensive cleaning of large surfaces.

2. Portability and Design

Lightweight, handheld models with ergonomic designs tend to cost less but offer limited power compared to industrial-grade models.

3. Cooling System

Air-cooled units are more affordable and easier to maintain, while water-cooled units, though more expensive, provide better performance during prolonged use.

4. Safety Features

Machines with enhanced safety features, such as emergency stop buttons, protective shields, and automatic shutdowns, may have a higher price tag but offer added protection for operators.

5. Smart Technology

Models equipped with smart interfaces and pre-programmed cleaning modes often cost more due to their convenience and automation capabilities.

Typical Price Ranges for Portable Laser Cleaning Machines

• Entry-Level Models (50W – 100W): $8,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-End Industrial Models (1000W and Above): $50,000+

Prices may vary based on optional accessories, warranties, and shipping fees.

Benefits of Portable Laser Cleaning Machines

1. Eco-Friendly and Chemical-Free

These machines don’t require harmful solvents, making them safer for users and environmentally sustainable.

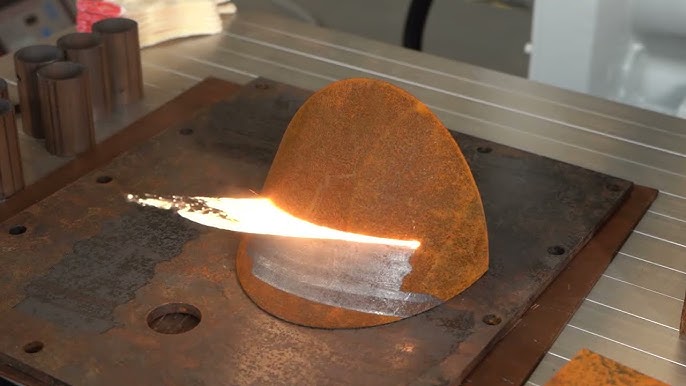

2. Non-Abrasive Cleaning

The laser removes contaminants without scratching or weakening the underlying surface, preserving the integrity of valuable components.

3. Precision and Control

Adjustable power settings allow for tailored cleaning, whether you’re working on delicate artifacts or heavy machinery.

4. Cost-Effective in the Long Run

While the upfront cost is significant, the elimination of consumables and reduced labor expenses result in long-term savings.

5. Portability and Versatility

Portable laser cleaners can be used on-site, making them ideal for applications such as outdoor maintenance and fieldwork.

Common Applications of Portable Laser Cleaning Machines

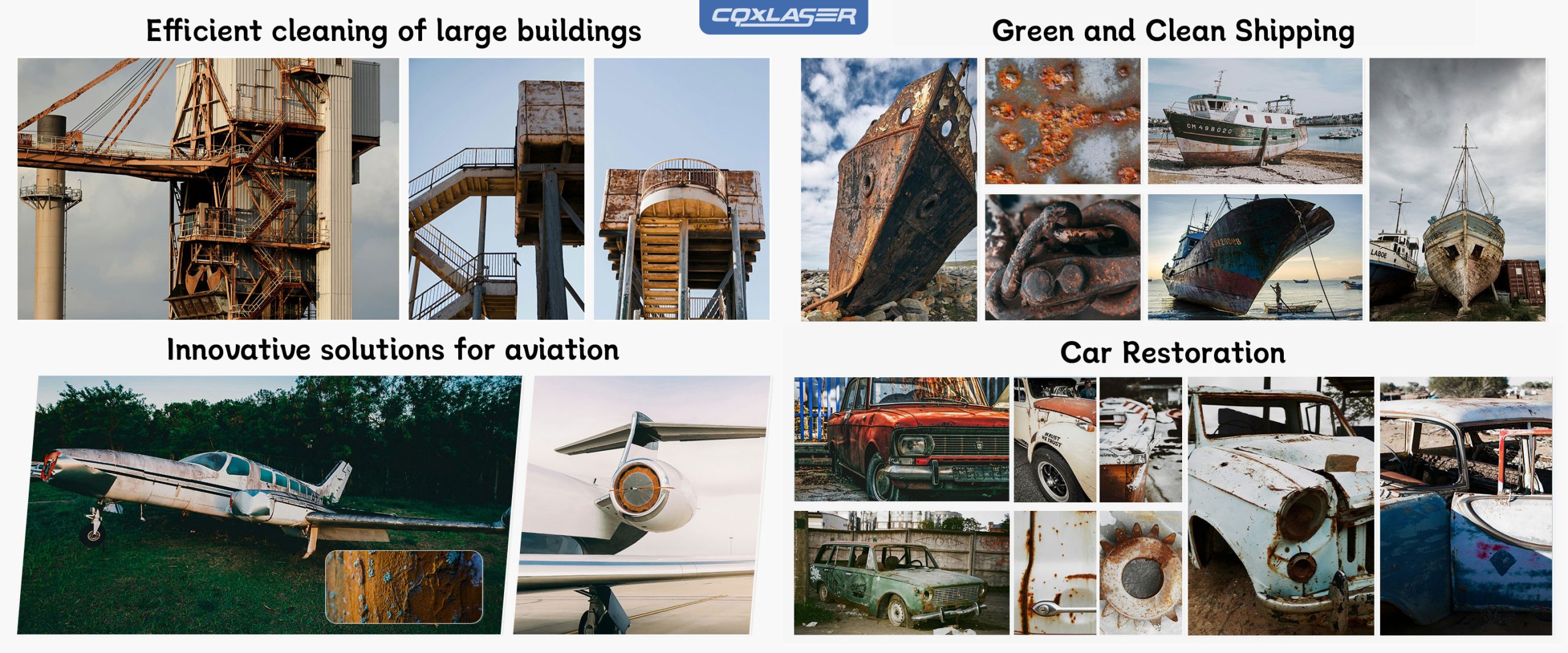

1. Automotive Restoration

These machines remove rust, grease, and old paint from car frames, engine parts, and custom restorations.

2. Aerospace Maintenance

Aircraft components require precise cleaning to maintain safety standards. Portable laser cleaners remove oxidation and residues without affecting structural integrity.

3. Industrial Manufacturing

Factories use portable laser cleaners for maintenance tasks, such as cleaning molds, conveyor belts, and production equipment.

4. Marine Repairs

Laser cleaning machines remove corrosion, salt deposits, and barnacles from ship hulls and offshore structures.

5. Cultural Heritage Preservation

Museums and restoration experts use portable laser cleaners to safely remove dirt and deposits from historical artifacts and sculptures.

Key Features to Look for When Buying a Portable Laser Cleaning Machine

1. Power Adjustments

Look for a machine with adjustable power levels to handle different cleaning tasks.

2. Efficient Cooling System

Choose an air-cooled system for lighter work or a water-cooled system for extended industrial use.

3. Ergonomic Design

Ensure the machine is lightweight and comfortable to use, with handles that reduce operator fatigue.

4. Safety Features

Check for essential safety measures, such as emergency stop buttons and protective eyewear.

5. Smart Controls

Some models feature touchscreen interfaces and pre-set cleaning modes, which make operation simpler and more efficient.

Maintenance Tips for Portable Laser Cleaning Machines

1. Clean the Lens: Keep the laser lens free of dust and debris to maintain precision.

2. Inspect Cooling Components: Ensure that air or water cooling systems function properly and are free of blockages.

3. Check Cables and Connections: Damaged cables can reduce performance and should be replaced promptly.

4. Follow Usage Guidelines: Adhere to recommended usage times to prevent overheating.

5. Store in a Safe Location: Keep the machine in a dry, dust-free space when not in use.

Recent Innovations in Portable Laser Cleaning Technology

The latest portable laser cleaners feature AI-driven sensors that adjust laser intensity based on surface conditions. Additionally, advancements in green laser technology enhance cleaning performance on non-metal surfaces, further expanding the range of applications.

Comparing Portable Laser Cleaning to Traditional Methods

1. Time Efficiency

Laser cleaning reduces surface preparation times significantly compared to manual scrubbing or chemical stripping.

2. Environmental Impact

Unlike abrasive blasting or chemical methods, laser cleaning produces no hazardous waste or chemical runoff.

3. Precision and Versatility

Lasers can target specific areas with incredible accuracy, making them ideal for intricate and detailed cleaning tasks.

How to Choose the Right Portable Laser Cleaning Machine

When selecting a portable laser cleaner, consider the following:

• Surface Material: Are you cleaning metal, stone, or a composite surface?

• Frequency of Use: Is the machine for occasional projects or continuous industrial operations?

• Power Needs: Choose a power output that matches your cleaning requirements.

• Portability Requirements: Do you need a handheld model for fieldwork or a larger unit for workshop use?

• Budget: Factor in the cost of the machine, accessories, and maintenance.

A portable laser cleaning machine is an investment that can transform your surface preparation process. By understanding price ranges, features, and applications, you can choose a model that meets your needs and delivers exceptional performance. Whether you’re maintaining machinery, restoring antique metalwork, or preserving cultural artifacts, a high-quality portable laser cleaner enhances efficiency, safety, and sustainability in your cleaning operations.