Portable Handheld Laser Cleaning Machine: The Ultimate Solution for Surface Cleaning

When it comes to modern cleaning solutions, few technologies can match the versatility, precision, and efficiency of a portable handheld laser cleaning machine. Picture a device that can strip away layers of rust, paint, and contaminants with surgical precision—all while remaining compact, mobile, and eco-friendly. Whether you’re in a workshop, a factory, or an outdoor site, these machines deliver powerful results without the need for harmful chemicals or abrasive scrubbing.

What Is a Portable Handheld Laser Cleaning Machine?

A portable handheld laser cleaning machine is a lightweight, mobile device designed to remove surface contaminants using concentrated laser beams. The laser beam heats and vaporizes layers of unwanted material, leaving the base surface clean and intact. This non-contact, non-abrasive method of cleaning is transforming industries that depend on precision and sustainability.

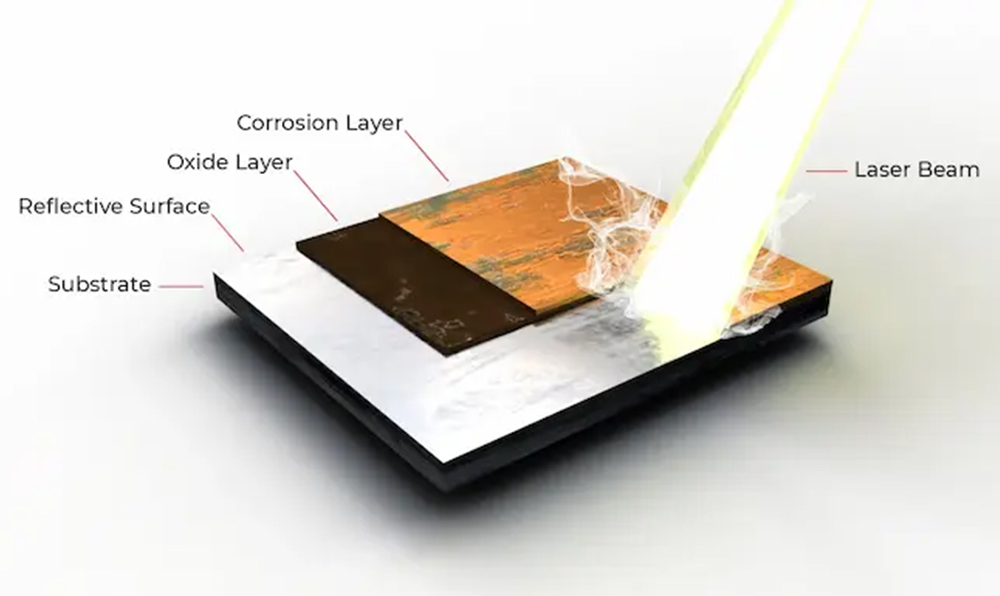

How Does It Work?

1.Energy Pulse Generation: The machine produces pulses of focused light energy.

2.Selective Absorption: The contaminant layer absorbs the laser energy, breaking it apart.

3.Material Vaporization: The unwanted material is vaporized into dust or small particles.

This method ensures that the underlying material remains unharmed, making it a superior choice for sensitive or intricate surfaces.

Advantages of Portable Handheld Laser Cleaning Machines

1. Mobility and Convenience

With their compact design and lightweight construction, portable handheld laser cleaners are ideal for fieldwork and mobile applications.

2. Chemical-Free Cleaning

Unlike sandblasting or grinding, laser cleaning preserves the structural integrity of the base material, making it ideal for delicate or high-value components.

3. Non-Abrasive Technology

The laser removes contaminants without scratching or damaging the underlying surface, preserving the integrity of valuable equipment and components.

4. Precision Control

Operators can adjust the laser’s power settings and beam focus, allowing for customized cleaning based on the material type and contamination level.

5. Time and Cost Efficiency

Laser cleaning significantly reduces the time required for surface preparation and eliminates the need for consumables like sand or cleaning agents.

Applications of Portable Handheld Laser Cleaning Machines

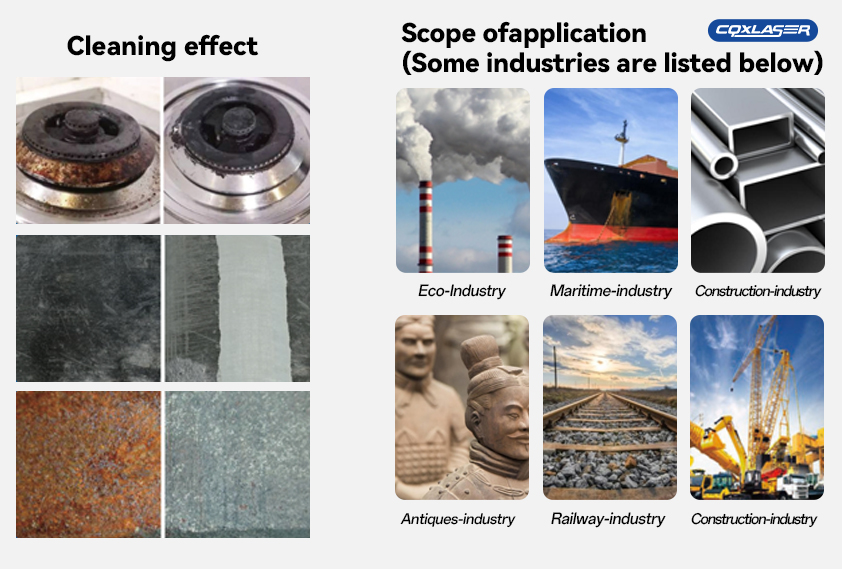

1. Automotive Restoration

These machines are commonly used to strip rust and paint from car frames, engine parts, and custom restorations without damaging the base metal.

2. Industrial Maintenance

Factories use handheld laser cleaning machines to clean molds, machinery, and production equipment, ensuring optimal performance with minimal downtime.

3. Aerospace Industry

Laser cleaning is critical for removing oxidation and contaminants from aircraft components, where precision and safety are paramount.

4. Cultural Heritage Preservation

Restorers use handheld laser cleaners to remove dirt and deposits from sculptures, monuments, and historical artifacts without damaging the original material.

5. Shipbuilding and Marine Repairs

Handheld lasers effectively remove salt residue, barnacles, and rust from ship hulls and offshore structures, preparing them for maintenance or repainting.

Types of Portable Handheld Laser Cleaning Machines

1. Low-Power Units (50W - 100W)

Suitable for light cleaning tasks, such as removing thin layers of rust or paint from delicate surfaces.

2. Mid-Power Units (200W - 500W)

Ideal for general industrial use, these models offer the perfect balance between power and mobility.

3. High-Power Units (1000W and Above)

These machines are designed for heavy-duty cleaning tasks, such as removing thick rust, corrosion, and coatings from large surfaces.

Key Features to Look for in a Portable Handheld Laser Cleaning Machine

1. Power Settings

Adjustable power settings allow for greater flexibility, enabling the machine to handle both delicate and tough cleaning tasks.

2. Cooling System

Efficient cooling systems (air-cooled or water-cooled) prevent overheating during extended use, ensuring consistent performance.

3. Portability and Ergonomics

A lightweight, well-balanced design with ergonomic handles makes the machine easier to operate for longer periods without causing fatigue.

4. Safety Features

Built-in safety measures, such as automatic shut-off and protective shielding, ensure safe operation.

5. Smart Controls

Some machines come equipped with smart interfaces and pre-programmed cleaning modes, simplifying operation and improving accuracy.

Cost of Portable Handheld Laser Cleaning Machines

The price of a portable handheld laser cleaning machine depends on its power output, features, and brand. Here’s a general breakdown:

• Entry-Level Models (50W – 100W): $8,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-Power Models (1000W and Above): $50,000+

Additional factors, such as included accessories, warranty coverage, and shipping fees, can also impact the final cost.

Maintenance Tips for Portable Handheld Laser Cleaning Machines

To ensure optimal performance and extend the lifespan of your laser cleaning machine:

1.Clean the Optics: Regularly check and clean the laser lens to prevent dust buildup.

2.Monitor the Cooling System: Ensure the cooling system is free from blockages or leaks.

3.Store in a Safe Environment: Keep the machine in a dry, dust-free location when not in use.

4.Follow Calibration Guidelines: Periodically calibrate the machine to maintain precision and efficiency.

Why Portable Handheld Laser Cleaning Machines Outperform Traditional Cleaning Methods

1. Versatility Across Industries

Laser cleaning machines can clean metal, ceramics, stone, and other materials, making them suitable for a wide range of applications.

2. Faster Cleaning Times

The high precision of laser cleaning significantly reduces the time needed for surface preparation compared to mechanical or chemical methods.

3. No Residue Left Behind

Unlike chemical cleaning, which often leaves behind sticky residues, laser cleaning leaves surfaces completely clean and residue-free.

4. Safer for Operators

Laser cleaning systems come with safety features that minimize operator exposure to harmful byproducts and ensure compliance with safety regulations.

Innovations in Portable Laser Cleaning Technology

Recent advancements in laser technology have made portable handheld laser cleaning machines more compact, energy-efficient, and affordable. Future trends may include AI-powered systems capable of detecting contamination levels and adjusting laser intensity automatically for optimized cleaning. Additionally, the development of green laser systems promises improved performance on non-metallic surfaces, expanding the potential applications of laser cleaning even further.

Choosing the Right Portable Handheld Laser Cleaning Machine

When selecting a laser cleaning machine, ask yourself:

• What type of surfaces will you be cleaning?

• How frequently will the machine be used?

• Do you need a model with high power or one that’s more portable?

• What is your budget for both initial investment and maintenance?

By considering these questions, you can choose a machine that meets your specific needs and delivers maximum value.

Portable handheld laser cleaning machines have redefined surface treatment with their unmatched precision, portability, and efficiency.

Whether you’re restoring antique metals, maintaining industrial machinery, or preparing surfaces for welding, these machines offer a cleaner, safer, and more sustainable solution. Understanding their features and applications ensures you get the most out of your investment and achieve superior cleaning results.