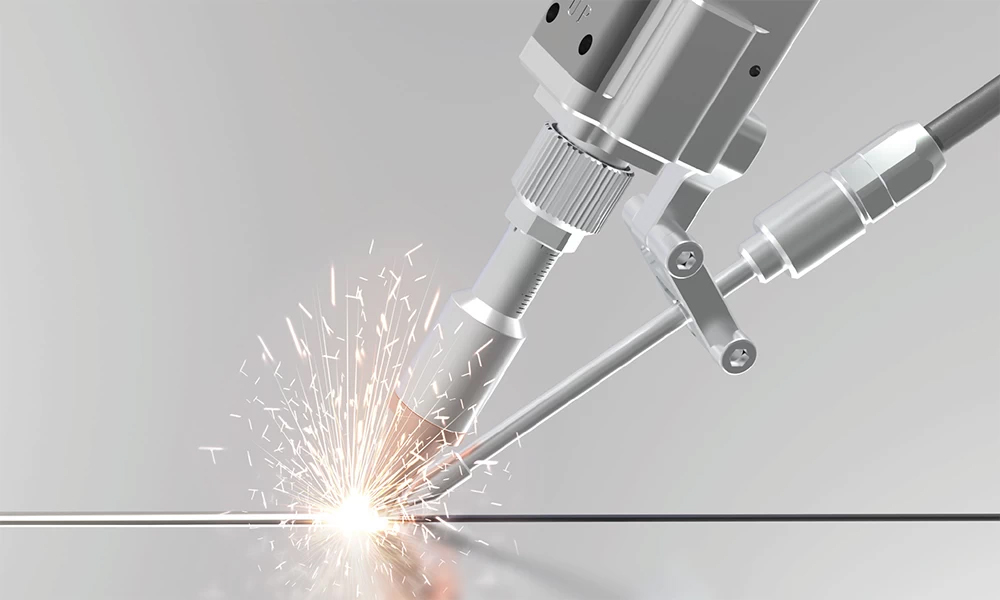

Laser Welding Tool: Precision Meets Power

A laser welding tool isn’t just a machine—it’s a revolution in metal joining. Imagine crafting flawless welds with unmatched precision and speed, reducing post-processing time while increasing productivity. This tool transforms welding by focusing light energy into a powerful beam capable of bonding metals with minimal distortion and maximum strength. Whether you’re working in automotive manufacturing, medical device creation, or fine jewelry repair, a laser welding tool brings precision and versatility to the forefront.

This comprehensive guide will break down everything you need to know about laser welding tools, from their working principles to real-world applications and essential purchasing tips.

1. What Is a Laser Welding Tool?

A laser welding tool is a high-precision device that uses a concentrated laser beam to join materials, typically metals or thermoplastics. Unlike traditional welding methods that rely on electrical currents or flames, this tool focuses energy directly at the joint, melting the material edges to form a seamless bond.

2. How a Laser Welding Tool Works

The core process of laser welding involves a series of precise steps:

1. Laser Beam Generation:The laser source produces an intense, focused beam of light.

2. Beam Focusing:The beam is directed through optical lenses, narrowing it into a concentrated point.

3. Material Melting:The beam strikes the material surface, creating a molten pool at the joint.

4. Cooling and Bonding:As the molten metal cools, it solidifies, creating a strong weld.

3. Types of Laser Welding Tools

3.1 Handheld Laser Welding Tools

These portable units offer flexibility and are designed for on-site or small workshop tasks.

• Best For:Repairs, small fabrications, and mobile welding tasks.

3.2 Benchtop Laser Welding Tools

Fixed systems designed for precise, detailed work.

• Best For:Jewelry making, electronics assembly, and medical device fabrication.

3.3 Automated Laser Welding Systems

Equipped with robotic arms and programmable settings, these tools are designed for high-speed industrial production.

• Best For:Automotive assembly lines, aerospace components, and mass production.

4. Key Features of a Laser Welding Tool

4.1 Power Output

Measured in watts, the power output determines how deep and quickly the tool can weld.

• Low Power (100W – 500W):Suitable for thin materials and fine details.

• High Power (1,000W – 6,000W):Ideal for thicker metal plates and faster welding speeds.

4.2 Beam Diameter

A narrow beam produces precise welds, while a wider beam offers more surface coverage for larger joints.

4.3 Cooling System

Efficient cooling (air or water-based) prevents overheating and maintains consistent performance.

4.4 Adjustable Pulse Settings

Some laser welding tools allow users to adjust pulse width and frequency, offering greater control over weld quality.

5. Benefits of Using a Laser Welding Tool

5.1 High Precision

The focused energy beam creates precise welds with minimal warping or distortion.

5.2 Faster Production

Laser welding can complete tasks up to four times faster than traditional methods, increasing overall productivity.

5.3 Minimal Post-Processing

Welds created by laser tools are smooth and clean, often requiring little to no sanding or grinding.

5.4 Versatility

Laser welding tools can handle various materials, including stainless steel, aluminum, copper, and titanium.

6. Common Applications of Laser Welding Tools

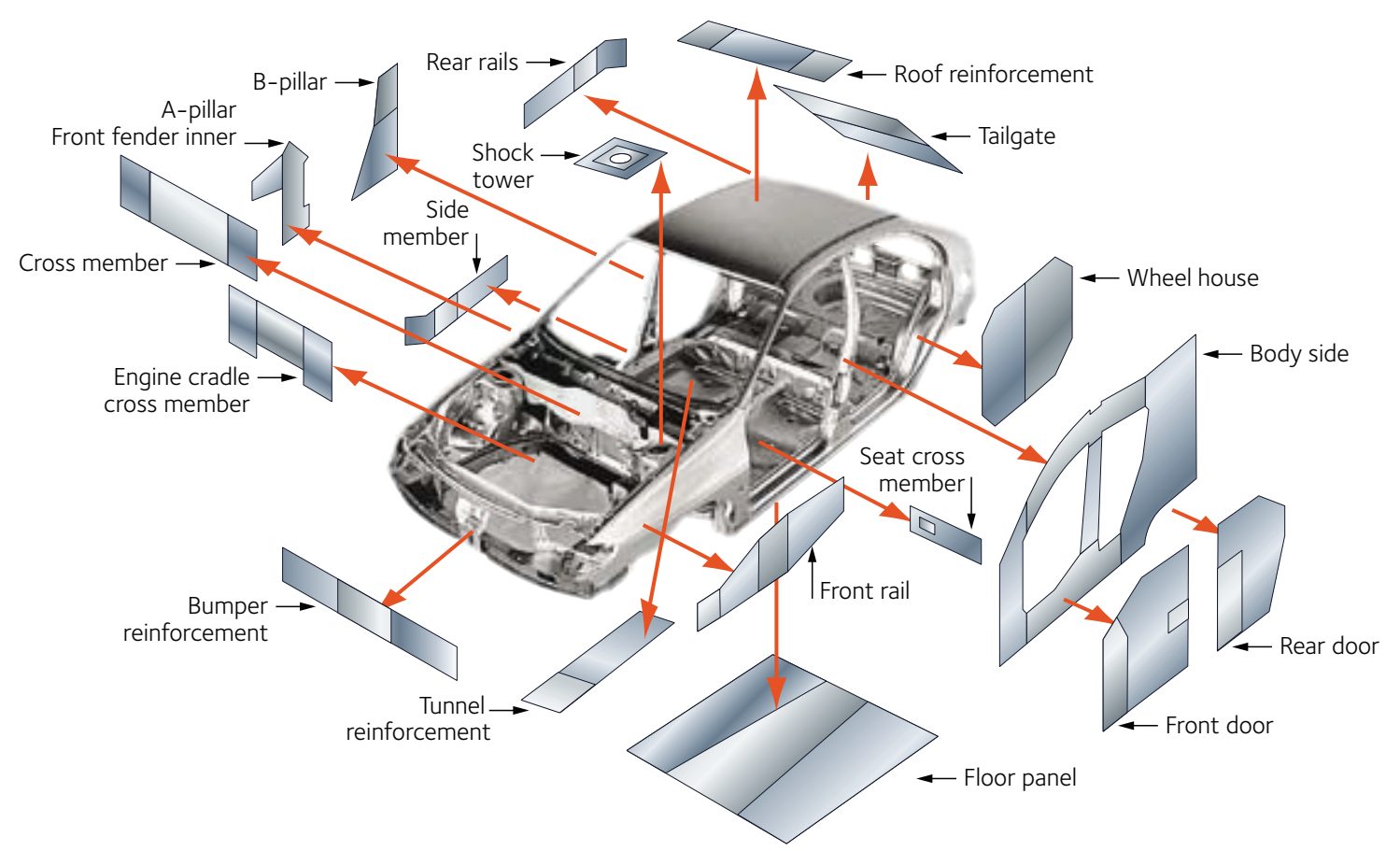

6.1 Automotive Industry

Used for assembling lightweight but durable vehicle frames, exhaust systems, and engine components.

6.2 Aerospace Engineering

Essential for joining high-strength materials used in aircraft and spacecraft construction.

6.3 Medical Equipment Production

Enables precise, contamination-free welding of surgical instruments, implants, and diagnostic devices.

6.4 Electronics Manufacturing

Creates precise joints for sensors, connectors, and microchips without damaging sensitive components.

6.5 Jewelry and Watchmaking

Allows for intricate repairs and seamless designs in fine metals like gold and platinum.

7. Cost Considerations for Laser Welding Tools

The cost of a laser welding tool varies widely based on its features and specifications:

• Entry-Level Handheld Models:$8,000 – $15,000

• Mid-Range Benchtop Units:$15,000 – $50,000

• High-End Automated Systems:$50,000 – $500,000+

8. Factors Affecting the Price

8.1 Power and Efficiency

High-power models capable of deep welds cost more but offer faster processing times.

8.2 Build Quality and Materials

Laser welding tools with robust casings and precision-engineered components often come at a premium.

8.3 Automation Level

Fully automated systems cost significantly more than manual or semi-automated units due to their advanced programming and robotic components.

8.4 Accessories and Add-Ons

Additional features like cooling upgrades, customized nozzles, and safety enclosures can increase the overall cost.

9. Comparing Laser Welding to Traditional Methods

| Method | Precision | Speed | Heat-Affected Zone | Post-Processing |

|---|---|---|---|---|

| Arc Welding | Moderate | Slow | Large | High |

| MIG Welding | Moderate | Fast | Medium | Medium |

| Laser Welding Tool | Very High | Fast | Minimal | Minimal |

10. Safety Guidelines for Operating Laser Welding Tools

Safety is crucial when working with high-powered laser systems:

1. Wear Protective Goggles:Use laser-rated goggles to protect your eyes from direct and reflected beams.

2. Ensure Proper Ventilation:Welding fumes should be extracted to maintain clean air.

3. Use Protective Enclosures:Enclose the welding area to prevent stray laser beams from escaping.

4. Check Cooling Systems:Regularly inspect cooling units to avoid overheating.

11. Emerging Trends in Laser Welding Tools

The laser welding market is rapidly evolving, driven by innovations that enhance efficiency and accessibility:

• Portable Laser Welders:Compact, battery-operated units for fieldwork and mobile repairs.

• AI-Assisted Welding:Systems that optimize weld parameters in real time using artificial intelligence.

• Eco-Friendly Lasers:Development of energy-efficient laser sources that reduce power consumption and emissions.

12. FAQs About Laser Welding Tools

Q: Can laser welding tools be used for thick metals?

A: Yes, high-power laser welding tools can handle metal sheets up to 10mm thick.

Q: Are laser welding tools difficult to maintain?

A: No, they require minimal maintenance, such as regular lens cleaning and occasional software updates.

Q: Do operators need training to use laser welding tools?

A: Basic training is recommended, but many tools feature user-friendly interfaces that simplify operation.

Laser welding tools have revolutionized metal joining with their precision, speed, and versatility. Understanding their capabilities, applications, and cost considerations allows businesses to make informed decisions about adopting this transformative technology. Whether used for industrial-scale production or intricate repairs, a laser welding tool is an essential asset for achieving high-quality results.