Laser Welding Machine for Sale: Precision Meets Power

Imagine a tool so advanced, so precise, that it transforms the very fabric of manufacturing. The laser welding machine is more than just a piece of equipment; it is a revolutionary technology that merges power with finesse, bringing intricate designs to life with pinpoint accuracy. Whether you’re crafting complex automotive components or repairing delicate metalworks, the search for the perfect laser welding machine for sale ends here. This comprehensive guide delves into everything you need to know—from types and applications to cost considerations and future trends—helping you make an informed decision for your business needs.

1.What is a Laser Welding Machine?

1.1 Overview of Laser Welding Technology

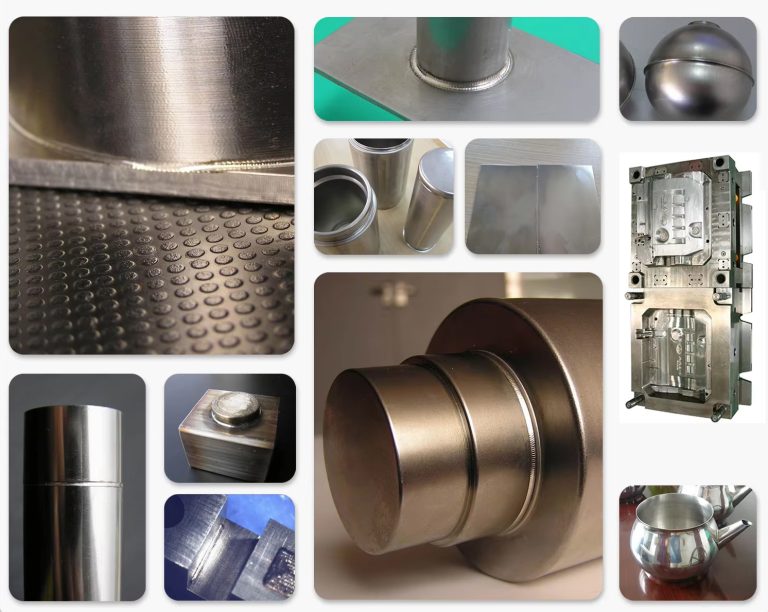

A laser welding machine uses a high-energy laser beam to melt and fuse materials, creating a precise and strong joint. The process involves minimal heat distortion and ensures accurate, clean welds. Laser welding stands out for its ability to join a variety of materials, including metals like stainless steel, aluminum, and even non-metallic surfaces.

1.2 Key Features of a Laser Welding Machine

• Precision: Focused laser beams ensure welds with minimal defects.

• Efficiency: The rapid speed of welding reduces production time significantly.

• Flexibility:Suitable for a wide range of materials and applications.

2.How Laser Welding Machines Work

2.1 The Science Behind Laser Welding

Laser welding involves focusing a concentrated laser beam on a targeted area, causing the material to heat and melt. As the laser moves along the welding line, the material cools and solidifies, forming a seamless weld. The high energy density of the laser ensures deep penetration, allowing for strong joints without compromising surrounding areas.

2.2 Components of a Laser Welding Machine

• Laser Source: The core element, typically a fiber or CO₂ laser, determines the power and application range.

• Cooling System: Maintains an optimal temperature, preventing overheating during operation.

• Control Interface: A user-friendly system that allows for adjustments to laser power, beam focus, and welding speed.

3. Types of Laser Welding Machines

3.1 Fiber Laser Welding Machines

Fiber lasers are renowned for their high efficiency, excellent beam quality, and low maintenance needs. These machines are ideal for welding reflective materials like aluminum and copper.

3.2 CO₂ Laser Welding Machines

CO₂ lasers are commonly used for non-metallic materials and thicker metals. They are versatile but tend to have higher maintenance requirements compared to fiber lasers.

3.3 Pulsed Laser Welding Machines

These machines are used for precision welding of small components and thin materials. Pulsed laser welding is preferred for applications requiring minimal heat input and high accuracy.

4. Advantages of Laser Welding Machines

4.1 Superior Welding Quality

Fiber lasers are renowned for their high efficiency, excellent beam quality, and low maintenance needs. These machines are ideal for welding reflective materials like aluminum and copper.

4.2 Speed and Efficiency

Compared to traditional welding methods, laser welding is significantly faster. The increased speed leads to higher productivity and reduced labor costs.

4.3 Minimal Heat Affected Zone

The concentrated nature of the laser beam results in a small heat affected zone (HAZ), which means there is less thermal stress and minimal warping of the welded components.

4.4 Flexibility Across Applications

Laser welding machines are used in industries ranging from automotive and aerospace to electronics and jewelry. Their ability to handle diverse materials makes them an incredibly versatile tool for manufacturers.

5. Applications of Laser Welding Machines

5.1 Automotive Industry

In the automotive sector, laser welding machines are used for tasks such as welding car bodies, exhaust systems, and battery components. Their precision ensures the structural integrity and safety of vehicles.

5.2 Aerospace and Defense

The aerospace industry relies on laser welding for its ability to create strong, lightweight welds. Components such as turbine blades and fuel tanks benefit from the accuracy and strength provided by laser technology.

5.3 Medical Device Manufacturing

The precision of laser welding is crucial in the medical field for producing devices like pacemakers, surgical instruments, and implants. The non-contact nature of laser welding ensures that delicate parts are joined without contamination.

5.4 Electronics and Microfabrication

Laser welding is ideal for the electronics industry, where micro-welding is required for circuit boards, sensors, and delicate components. The accuracy of the laser ensures minimal damage to surrounding areas.

6. Factors to Consider When Buying a Laser Welding Machine

6.1 Power Requirements

Choosing the right power output is essential for achieving the desired weld depth and quality. The type of material and its thickness will determine the power requirements of the laser welding machine.

6.2 Type of Laser Source

The type of laser—fiber, CO2, or diode—plays a critical role in determining the machine’s application. Fiber lasers are versatile, while CO2 lasers are better suited for non-metallic materials.

6.3 Cooling Mechanism

An efficient cooling system is crucial for the continuous operation of a laser welding machine. Water-cooled systems are generally more effective for heavy-duty applications compared to air-cooled options.

6.4 Budget and ROI

The initial investment in a laser welding machine can be high, but the long-term benefits of reduced labor, increased productivity, and lower maintenance costs provide a good return on investment.

6.5 Supplier Reliability

Working with a trusted supplier like CQX ensures that you receive a high-quality machine with comprehensive support and maintenance services.

7. How CQX Leads the Market with Laser Welding Machines

7.1 Innovative Technology

CQX is at the forefront of laser welding technology, providing machines that incorporate the latest advancements for enhanced performance. Their machines are designed for efficiency, precision, and durability.

7.2 Customer Support and Training

CQX offers extensive training and after-sales support, ensuring that users are fully equipped to operate their laser welding machines efficiently and safely. This commitment to customer satisfaction sets CQX apart in the competitive market.

8. Laser Welding Machines vs. Traditional Welding Methods

8.1 Heat Input and Material Distortion

Traditional welding methods often produce a large heat affected zone, which can lead to material distortion. Laser welding, by contrast, produces minimal heat, reducing the risk of warping and weakening of the welded area.

8.2 Speed of Operation

Laser welding is faster compared to conventional welding methods like TIG or MIG. This increased speed leads to higher throughput, making laser welding ideal for mass production environments.

8.3 Flexibility in Applications

While traditional welding methods have limitations based on material type and thickness, laser welding offers flexibility for a wide range of applications, from micro-welding to deep penetration welding.

9. Future Trends in Laser Welding Machines

9.1 Automation and Robotics

The integration of automation and robotics with laser welding machines is expected to increase, allowing for fully automated production lines that enhance productivity and precision.

9.2 Advancements in Beam Quality

Ongoing research into improving laser beam quality will lead to better welding results, with finer control and reduced defects. This will expand the range of applications for laser welding machines.

9.3 Green Manufacturing

As industries move toward sustainable practices, laser welding machines offer an eco-friendly solution due to their energy efficiency and minimal waste production.

A laser welding machine for sale represents an investment in precision, efficiency, and the future of manufacturing. Whether you are a large-scale manufacturer looking for a high-powered solution or a small business in need of a flexible welding tool, understanding the different options and features available will help you make the best choice. CQX offers a range of laser welding machines designed to meet various industrial needs, ensuring that each weld is of the highest quality, every time.