The Comprehensive Guide to Laser Welder for Sale: A Revolution in Manufacturing

In the ever-evolving landscape of manufacturing, precision and efficiency have become the cornerstones of success. Amid this revolution, the rise of laser welding technology has paved the way for unparalleled advancements in industrial processes. This guide delves deep into the world of laser welders for sale, uncovering their immense potential, applications, and benefits for modern industries. Whether you’re a seasoned professional or a newcomer exploring this technology, this article provides a complete understanding of why investing in a laser welder is a step toward the future.

1.The Rise of Laser Welding: A Historical Perspective

1.1 The Origins of Laser Welding

Laser welding technology dates back to the mid-20th century when scientists first discovered the power of concentrated light energy. Initial applications were limited to research settings, but rapid advancements in laser technology throughout the 1970s and 1980s led to its introduction into industrial manufacturing.

1.2 Evolution of Laser Welding Machines

From rudimentary prototypes to highly sophisticated systems, laser welders have undergone significant transformations. Today, laser welders for sale offer unmatched precision, flexibility, and reliability, thanks to innovations like fiber lasers, diode lasers, and CO₂ laser systems.

2. How Laser Welding Works

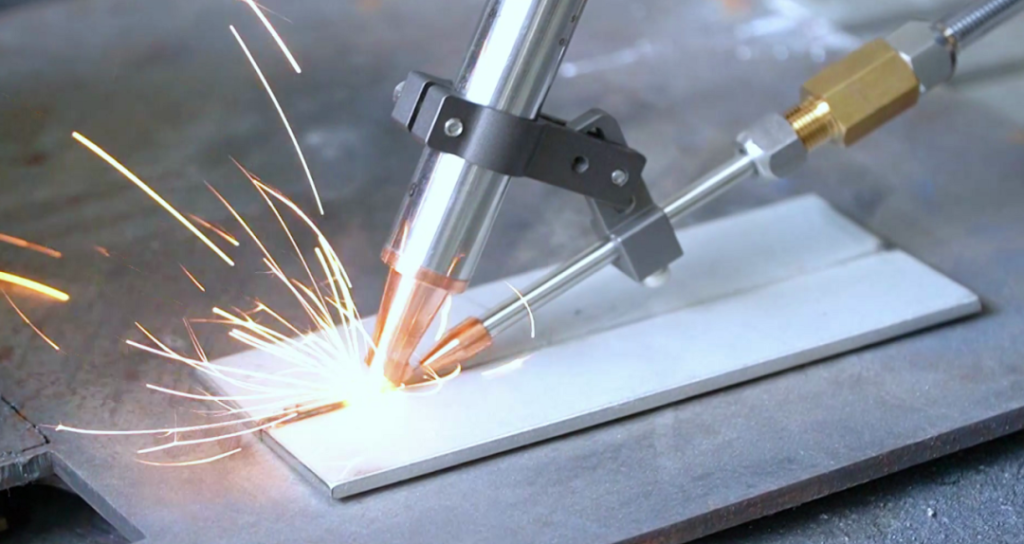

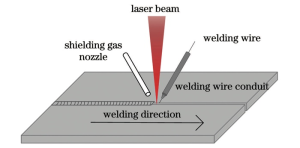

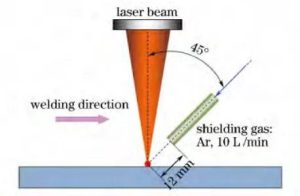

2.1 The Science Behind Laser Welding

Laser welding uses concentrated light energy to heat and melt materials, creating a strong bond. Unlike traditional welding techniques, which rely on physical contact or extensive heat application, laser welding ensures minimal distortion and maximum precision.

2.2 Types of Laser Welding

Conduction Welding: Suitable for thin materials, relying on heat conduction.

Keyhole Welding: Ideal for deeper welds, utilizing high-intensity beams to vaporize material and create a keyhole effect.

Hybrid Laser Welding: Combines laser welding with other techniques for enhanced efficiency.

3. Advantages of Laser Welders

3.1 Precision and Accuracy

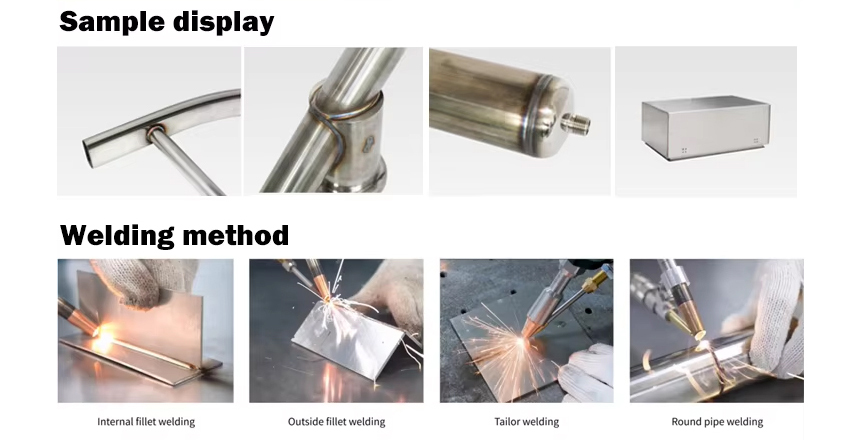

Laser welding delivers unmatched precision, enabling the creation of intricate designs and micro-welds that are impossible with traditional methods.

3.2 Speed and Efficiency

Laser welders significantly reduce production time, allowing manufacturers to meet tight deadlines without compromising quality.

3.3 Versatility

From aerospace to jewelry making, laser welders excel across a wide range of industries, adapting to various materials like steel, aluminum, and even delicate alloys.

3.4 Sustainability

By reducing energy consumption and material waste, laser welding contributes to sustainable manufacturing practices, aligning with global environmental goals.

4. Applications of Laser Welders

4.1 Automotive Industry

Laser welding plays a pivotal role in assembling car frames, batteries for electric vehicles, and intricate components like fuel injectors.

4.2 Medical Equipment Manufacturing

The medical field benefits immensely from laser welders’ precision, using them to create devices such as pacemakers, surgical tools, and implants.

4.3 Electronics and Microfabrication

From circuit boards to sensors, laser welding ensures precise connections in miniaturized electronic components.

4.4 Aerospace and Defense

Laser welding’s ability to handle lightweight and heat-resistant materials makes it indispensable in aerospace applications, such as building aircraft structures and missile components.

5.Factors to Consider When Buying a Laser Welder

5.1 Power Requirements

Choose a laser welder that aligns with the materials and thickness you intend to weld.

5.2 Cooling Mechanism

Efficient cooling systems are essential to prevent overheating and ensure consistent performance. 5.3 Portability and Design

Compact designs are ideal for workshops with limited space, while larger systems cater to high-volume industrial production.

5.4 Cost vs. ROI

While initial costs can be high, the long-term benefits of efficiency and reduced waste often outweigh the investment.

5.5 Supplier Reliability

Brands like CQX have established a reputation for delivering high-quality laser welders, backed by robust customer support and warranty options.

6. Understanding Laser Welder Specifications

6.1 Key Parameters

Wavelength: Determines the type of materials that can be welded.

Pulse Energy: Impacts the strength and depth of the weld.

Beam Quality: Affects precision and efficiency.

6.2 Safety Features

Modern laser welders incorporate safety measures such as enclosed systems, protective eyewear, and automatic shutdowns to ensure user safety.

7. Trends Shaping the Laser Welding Industry

7.1 Automation and AI Integration

Automation and artificial intelligence are transforming laser welding, enabling real-time monitoring, defect detection, and optimization of welding parameters.

7.2 Green Manufacturing

Laser welding’s energy efficiency aligns with the push toward eco-friendly manufacturing practices.

7.3 Expansion into New Markets

Emerging industries like renewable energy and wearable technology are embracing laser welding for their unique needs.

8. Common Myths About Laser Welders Debunked

8.1 Laser Welders Are Too Expensive

While the initial investment is higher, the long-term savings in efficiency, quality, and reduced waste make laser welders cost-effective.

8.2 They Are Only for Large Industries

Compact and affordable options now cater to small businesses and hobbyists.

8.3 Laser Welding Is Not Durable

Advancements in technology ensure welds are strong, durable, and often outperform traditional methods.

9. Maintenance and Troubleshooting Tips for Laser Welders

9.1 Routine Maintenance

Regularly clean lenses and mirrors to ensure optimal beam quality.

Inspect cooling systems and replace fluids as needed.

9.2 Troubleshooting Common Issues

Beam Misalignment: Adjust mirrors or consult the manufacturer.

Inconsistent Welds: Check for contamination or power fluctuations.

10. The Future of Laser Welding Technology

10.1 Innovations on the Horizon

Research into ultrafast lasers and hybrid welding systems promises even greater efficiency and precision.

10.2 Expanding Accessibility

As technology advances, laser welders are becoming more affordable, opening doors for wider adoption across industries.

The growing demand for laser welders for sale reflects a broader shift toward precision, efficiency, and sustainability in manufacturing. As industries continue to innovate, laser welding stands as a testament to how technology can redefine what’s possible. By understanding the intricacies of this technology and making informed purchasing decisions, businesses can unlock new levels of productivity and quality, ensuring a competitive edge in today’s fast-paced world.

If you’re ready to invest in the future, explore the range of CQX laser welders designed to meet diverse industry needs and elevate your production capabilities.