Laser Weld Machine: Precision Meets Power in Modern Welding

A laser weld machine is more than just a tool—it’s a leap into precision, speed, and unparalleled strength. Imagine creating flawless, durable joints with minimal heat impact, reduced distortion, and unmatched efficiency. This machine has transformed industries like aerospace, automotive, and electronics, where precision and durability are non-negotiable.

This in-depth guide explores how a laser weld machine works, its advantages, types, and applications. We’ll also cover essential tips for choosing the right machine for your needs and key safety practices for optimal performance.

1. What is a Laser Weld Machine?

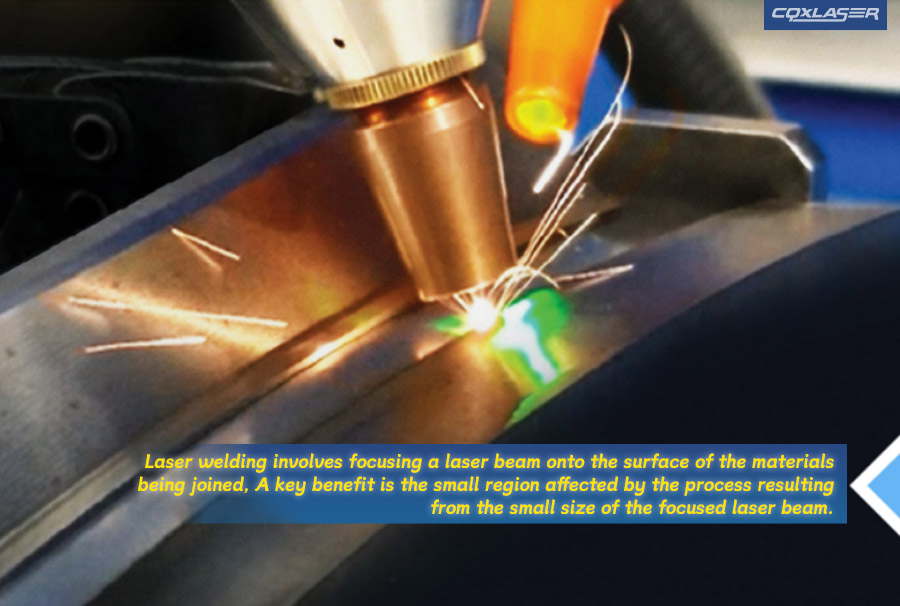

A laser weld machine uses a concentrated beam of light to fuse two materials, typically metals or thermoplastics. Unlike traditional welding, it creates high-strength joints with minimal heat-affected zones (HAZ), reducing material deformation and post-weld finishing.

2. How Does a Laser Weld Machine Work?

A laser weld machine follows a precise process to achieve clean and strong welds:

1. Laser Generation:The machine’s fiber or solid-state laser source generates an intense beam of coherent light.

2. Beam Focusing:Optical lenses focus the laser into a narrow point, directing it onto the welding surface.

3. Melting and Fusion:The beam melts the edges of the materials, forming a molten pool.

4. Solidification:As the beam moves or stops, the molten metal cools and solidifies into a seamless bond.

The combination of controlled energy input and rapid cooling ensures strong, defect-free welds.

3. Key Components of a Laser Weld Machine

• Laser Source:Generates the beam used for welding.

• Focusing Optics:Directs and focuses the beam for precision.

• Control System:Adjusts parameters such as beam intensity, speed, and pulse frequency.

• Workstation:Holds the materials in place for accurate welding.

• Cooling System:Prevents overheating by dissipating excess heat.

4. Types of Laser Weld Machines

4.1 Handheld Laser Weld Machines

Portable and easy to use, these machines are ideal for on-site repairs and small-scale projects.

• Best For:Mobile repairs, metal fabrication, and fieldwork.

4.2 Benchtop Laser Weld Machines

Fixed, compact units designed for detailed and precise work in controlled environments.

• Best For:Jewelry making, electronics assembly, and medical device production.

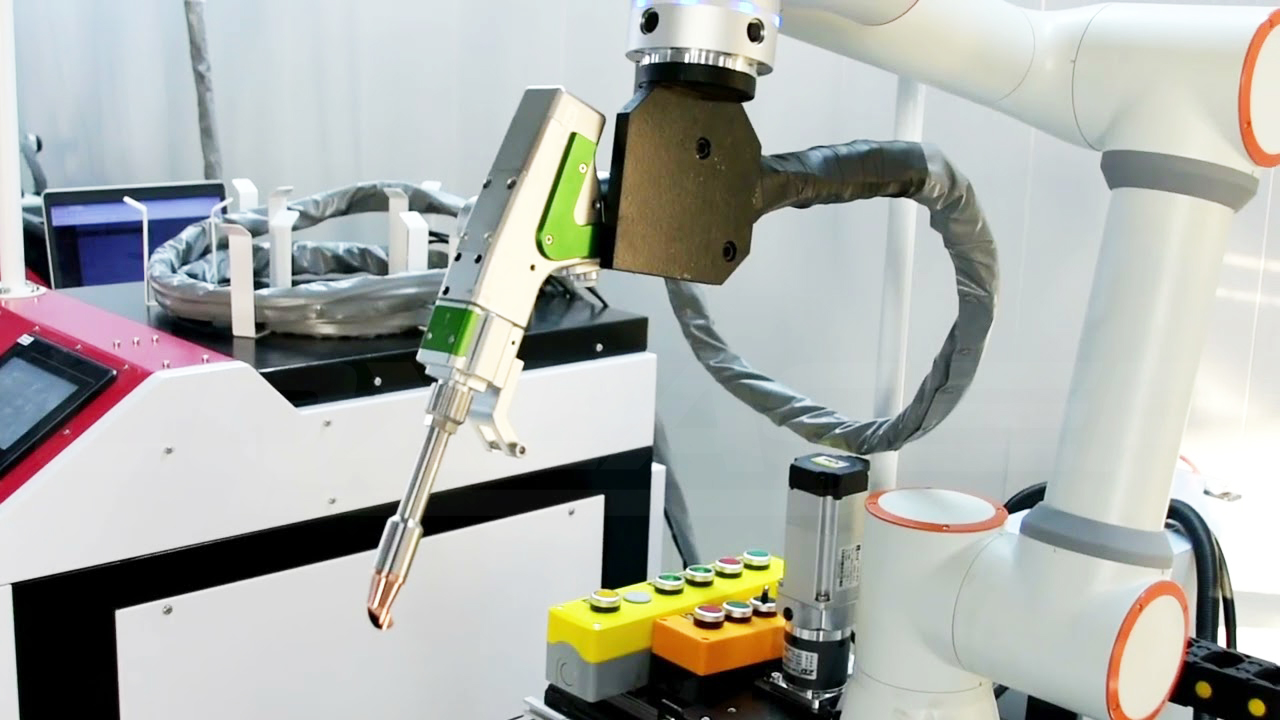

4.3 Automated Laser Welding Systems

Fully automated systems with robotic arms and programmable controls for large-scale production.

• Best For:Automotive assembly, aerospace components, and industrial production lines.

5. Key Advantages of Laser Weld Machines

5.1 High Precision

The focused laser beam creates precise welds, making it ideal for intricate designs and delicate parts.

5.2 Speed and Efficiency

Laser welding completes tasks faster than traditional welding methods, increasing overall productivity.

5.3 Minimal Heat-Affected Zones (HAZ)

The controlled energy input minimizes thermal distortion and preserves the structural integrity of surrounding materials.

5.4 Versatility

Laser weld machines work with various materials, including stainless steel, aluminum, copper, and titanium.

5.5 Clean Welds with Minimal Post-Processing

The smooth and uniform welds often require little to no grinding, sanding, or polishing.

6. Common Applications of Laser Weld Machines

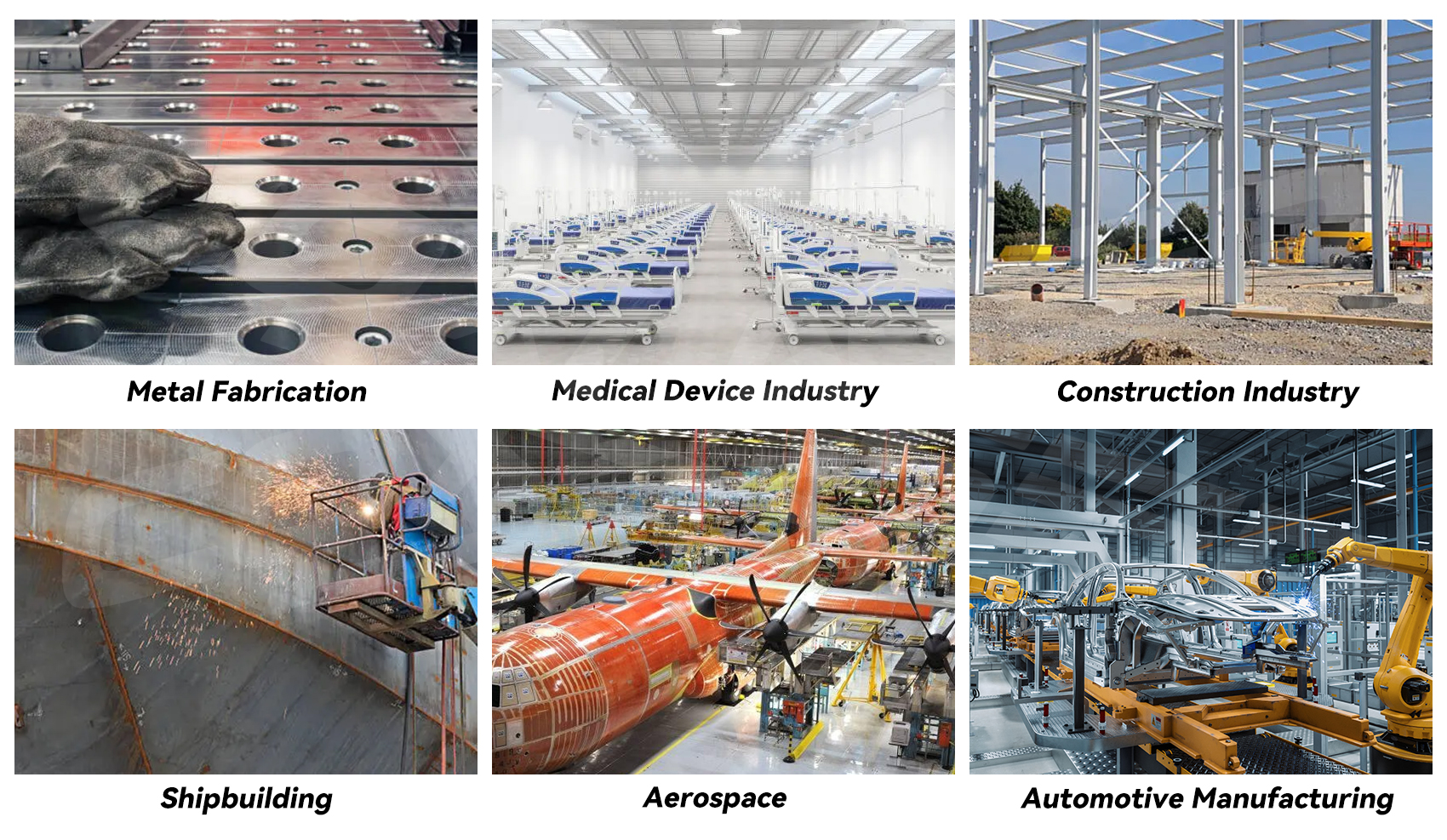

6.1 Aerospace Manufacturing

Laser weld machines join lightweight, high-strength components used in aircraft and spacecraft.

6.2 Automotive Industry

Automotive manufacturers use laser welding for assembling car frames, exhaust systems, and engine components.

6.3 Medical Devices

Laser welds create contamination-free, high-precision seams in surgical instruments, implants, and diagnostic tools.

6.4 Electronics Production

Used to assemble microelectronics, circuit boards, and sensors without damaging delicate components.

6.5 Jewelry and Fine Metalwork

Laser weld machines enable the creation of seamless joints in precious metals like gold, silver, and platinum.

7. Choosing the Right Laser Weld Machine

When selecting a laser weld machine, consider the following factors:

7.1 Power Output

Measured in watts, the power level determines how deep and fast the machine can weld.

• Low Power (100W – 500W):Suitable for thin materials and intricate work.

• Mid-Range Power (500W – 1,500W):Ideal for general fabrication tasks.

• High Power (2,000W+):Necessary for thick metals and industrial applications.

7.2 Beam Diameter and Focus

A smaller beam diameter provides more precise welds, while a wider beam covers larger surface areas.

7.3 Automation Level

Consider whether you need a manual, semi-automated, or fully automated system based on your production needs.

7.4 Cooling System

A robust cooling system (air or water-cooled) prevents overheating and ensures consistent performance.

7.5 Portability

For fieldwork or mobile repairs, choose a portable unit with ergonomic features for easy handling.

8. Cost Breakdown of Laser Weld Machines

The cost of a laser weld machine varies based on features and capabilities:

• Entry-Level Handheld Machines:$8,000 – $20,000

• Mid-Range Benchtop Systems:$20,000 – $50,000

• High-End Automated Systems:$50,000 – $500,000+

Additional costs may include installation, training, and maintenance expenses.

9. Comparing Laser Weld Machines to Traditional Methods

| Welding Method | Precision | Speed | Heat-Affected Zone | Post-Processing |

|---|---|---|---|---|

| MIG Welding | Moderate | Fast | Large | High |

| TIG Welding | High | Slow | Medium | Moderate |

| Laser Weld Machine | Very High | Very Fast | Minimal | Minimal |

Laser weld machines outperform traditional methods in precision, speed, and overall weld quality.

10. Safety Considerations for Laser Weld Machines

To operate a laser weld machine safely, follow these precautions:

1. Wear Protective Goggles:Protect your eyes with laser-rated goggles.

2. Maintain Proper Ventilation:Ensure the workspace is well-ventilated to dissipate fumes.

3. Use Protective Enclosures:Shield the welding area to prevent exposure to stray beams.

4. Inspect Cooling Systems:Regularly check cooling units to prevent overheating.

11. Latest Innovations in Laser Welding Technology

11.1 AI-Assisted Weld Optimization

AI algorithms adjust parameters in real time for consistent, high-quality welds.

11.2 Multi-Beam Welding

Advanced systems use multiple beams to increase weld speed and joint strength.

11.3 Portable Laser Welders

Compact, battery-operated units offer greater mobility for on-site repairs.

12. Frequently Asked Questions About Laser Weld Machines

Q: How thick can a laser weld machine weld?

A: High-power machines can weld metal sheets up to 10mm thick or more.

Q: Do laser weld machines require much maintenance?

A: They require minimal maintenance, such as lens cleaning and software updates.

Q: Is laser welding suitable for load-bearing components?

A: Yes, laser welds are often as strong or stronger than the base material.

A laser weld machine represents the pinnacle of modern welding technology, offering unparalleled precision, speed, and versatility. Understanding its features, applications, and benefits can help you choose the right machine for your specific needs and improve your welding processes significantly. Whether you’re in aerospace engineering, electronics manufacturing, or jewelry making, this innovative tool can elevate your production capabilities.