Laser Rust Cleaning Machine Price: A Complete Guide to Cost and Value

The search for the best laser rust cleaning machine price often raises the question: Is investing in this technology worth it? Laser rust cleaning machines have revolutionized surface preparation, offering precision, speed, and eco-friendly performance. Whether you need a portable handheld unit or an industrial-grade solution, understanding the factors that influence price can help you make an informed decision without overspending.

What Is a Laser Rust Cleaning Machine?

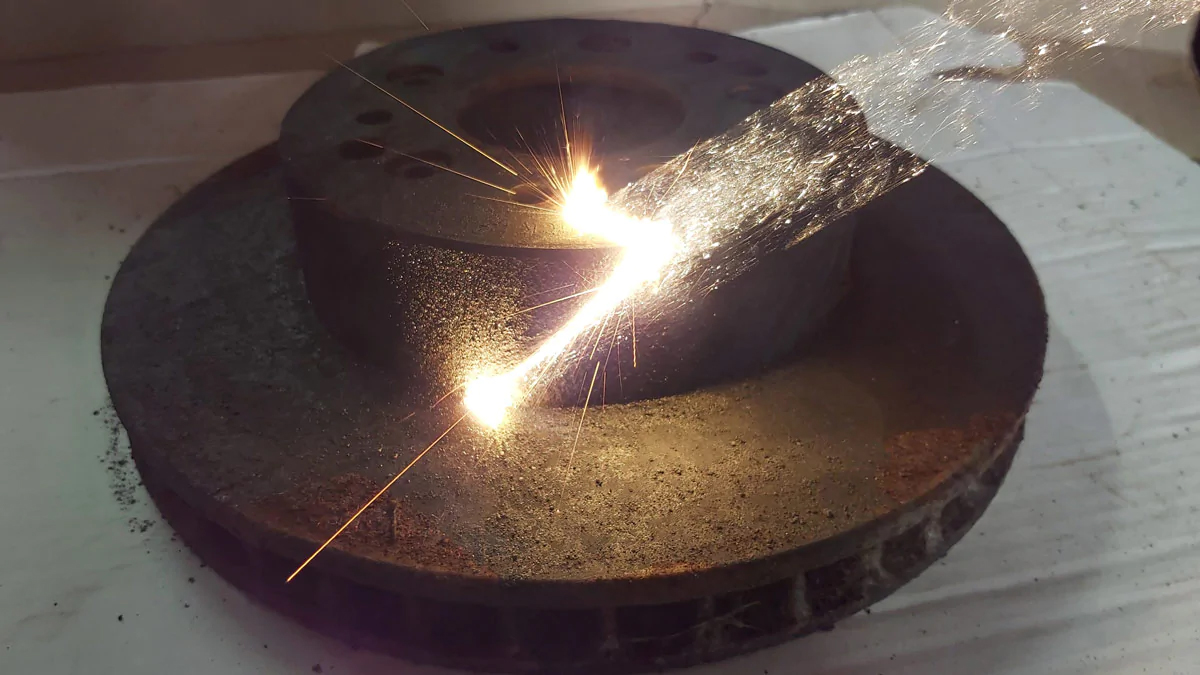

A laser rust cleaning machine uses concentrated laser beams to remove surface contaminants like rust, paint, and grime without damaging the underlying material. This process, known as laser ablation, vaporizes unwanted layers while preserving the surface’s integrity.

How Laser Rust Cleaning Works

1. Laser Emission: The machine directs laser pulses at the surface.

2. Selective Absorption: Rust and contaminants absorb the laser energy and disintegrate.

3. Vaporization: The contaminants turn into vapor or dust, leaving the surface clean and smooth.

This non-contact cleaning method ensures that even delicate surfaces remain unscathed, making it ideal for various industries.

Why Consider a Laser Rust Cleaning Machine?

Investing in a laser rust cleaning machine can save time, reduce labor costs, and eliminate the need for abrasive chemicals. The initial price may seem high, but the long-term benefits make it a cost-effective solution.

Factors That Affect Laser Rust Cleaning Machine Price

1. Power Output

Laser machines with higher wattage provide faster cleaning and can handle deeper rust layers.

• Low Power (50W – 100W): Suitable for light rust removal tasks.

• Medium Power (200W – 500W): Ideal for industrial use, offering a balance of power and speed.

• High Power (1000W and Above): Designed for heavy-duty cleaning tasks, such as removing thick rust and industrial coatings.

2. Portability and Design

Handheld laser rust cleaning machines tend to be more affordable than large, stationary units. Portable models offer the flexibility to perform cleaning tasks in different locations, making them an excellent choice for fieldwork.

3. Cooling System

Air-cooled systems are more cost-effective and compact, while water-cooled systems, though more expensive, are better for extended use and high-power machines.

4. Automation Features

Machines with automated settings, smart interfaces, and programmable modes may come at a higher price but provide greater convenience and precision.

5. Safety Features

Built-in safety measures such as emergency stop buttons, protective shields, and auto shut-off features can add to the overall cost.

Typical Price Ranges for Laser Rust Cleaning Machines

Here’s a breakdown of the typical price ranges:

• Entry-Level Models (50W – 100W): $8,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-End Industrial Models (1000W and Above): $50,000+

Prices may vary based on supplier, included accessories, and warranty options.

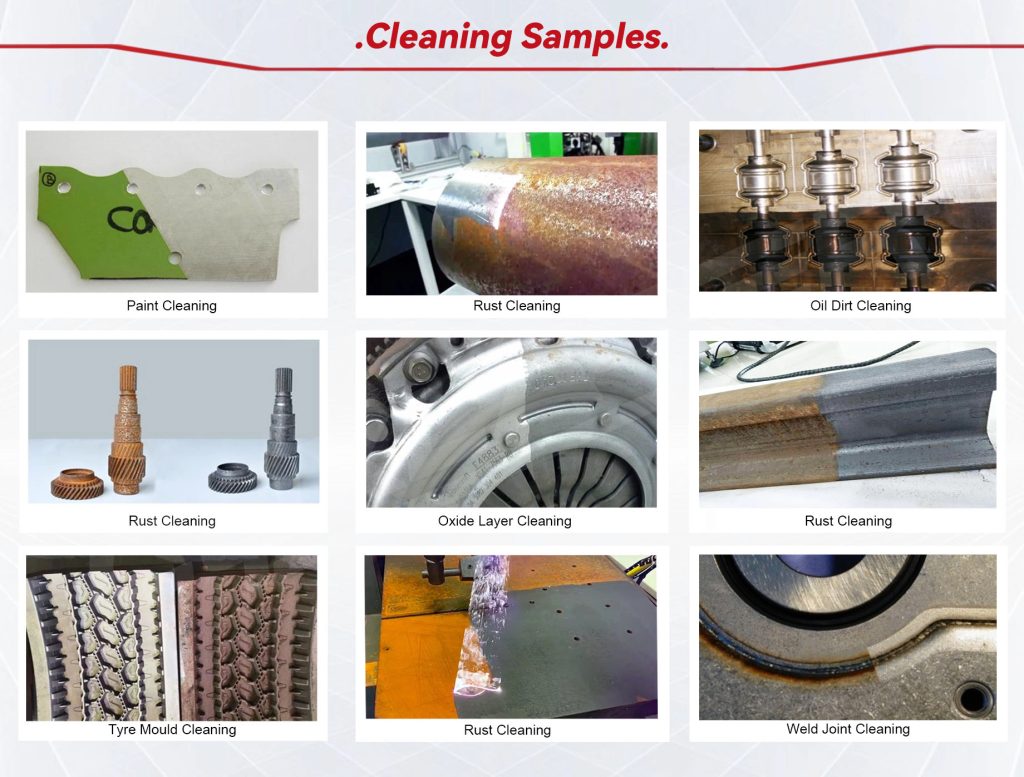

Applications of Laser Rust Cleaning Machines

1. Automotive Industry

Laser cleaning machines remove rust and paint from car frames, engine components, and suspension systems, ensuring a smooth surface for repainting or repairs.

2. Industrial Manufacturing

Factories use laser cleaning machines to maintain machinery, clean molds, and prepare surfaces for welding or bonding, minimizing downtime.

3. Aerospace Maintenance

Laser rust cleaning is used to remove oxidation and contaminants from aircraft components without compromising the structural integrity of the parts.

4. Shipbuilding and Marine Industry

Portable laser machines remove corrosion, salt deposits, and marine growth from ship hulls, decks, and offshore platforms.

5. Cultural Heritage Restoration

Conservation experts use laser cleaning to restore sculptures, monuments, and historical artifacts by removing dirt and deposits without damaging the original material.

Key Features to Look for When Buying a Laser Rust Cleaning Machine

1. Power Control Options

Adjustable power settings allow you to clean a variety of surfaces, from delicate artifacts to industrial equipment.

2. Cooling System Efficiency

Choose a system that suits your workload—air-cooled for occasional use or water-cooled for continuous, heavy-duty tasks.

3. Ergonomic Design

Handheld units should have a lightweight, well-balanced design for comfortable operation during long cleaning sessions.

4. Safety Features

Ensure the machine includes emergency stop buttons, protective goggles, and automatic shut-off mechanisms.

5. Smart Interfaces

Machines with touchscreen controls, pre-set cleaning modes, and remote monitoring capabilities enhance usability.

Maintenance Tips for Laser Rust Cleaning Machines

1. Clean the Laser Lens: Regularly remove dust and debris to maintain precision.

2. Check the Cooling System: Ensure there are no blockages or leaks in water-cooled units.

3. Inspect Fiber Cables: Damaged cables can reduce laser efficiency and should be replaced as needed.

4. Follow Recommended Usage Times: Avoid overheating by adhering to the manufacturer’s guidelines.

Innovations in Laser Rust Cleaning Technology

Recent advancements have made laser rust cleaning machines more efficient and affordable. Modern systems feature smart sensors that automatically adjust the laser intensity based on the surface material and contamination level. Additionally, energy-efficient lasers are being developed to reduce power consumption without sacrificing performance.

Comparing Laser Rust Cleaning to Traditional Methods

1. Time Efficiency

Laser cleaning significantly reduces the time needed for surface preparation compared to manual scraping or chemical stripping.

2. Cost Savings

Although the upfront cost of a laser rust cleaning machine may be higher, the elimination of consumables and reduced labor expenses result in long-term savings.

3. Environmental Impact

Laser cleaning produces no harmful waste or chemical runoff, making it a sustainable alternative to traditional methods.

4. Precision and Control

Laser machines allow operators to target specific areas with high precision, preventing damage to surrounding surfaces.

| Comparison Items | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Rust Removal | Ultrasonic Cleaning |

|---|---|---|---|---|---|

| Working Principle | Laser | Chemical Cleaner | Sandpaper/Grinding Wheel | Dry Ice | Cleaning Agent |

| Contactless | Yes | No | No | Yes | No |

| No damage to workpiece | Yes | No | No | Yes | Yes |

| Cleanliness | High | Uneven | Uneven | Uneven | Small cleaning range |

| Cleaning Efficiency | High | Low | Low | Medium | Medium |

| Accuracy | High accuracy (Controllable) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Uncontrollable (poor accuracy) | Can't be specified (range cleaning) |

| Environmental Friendly | Yes | No | No | Yes | No |

| Manual Operation | Simple | Complex | Protective measuresrequired | Simple | Simple |

| Consumables | No | Yes | Yes | Yes | Yes |

How to Choose the Right Laser Rust Cleaning Machine

When selecting a laser rust cleaning machine, consider these key questions:

• What type of surfaces will you be cleaning?

• How often will the machine be used?

• Do you need a portable handheld unit or a stationary model?

• What is your budget for both the machine and maintenance costs?

By answering these questions, you can narrow your options and choose a machine that fits your needs and operational goals.

Laser rust cleaning machines are transforming surface preparation with their efficiency, precision, and environmental benefits. Whether you’re maintaining industrial machinery, restoring vintage cars, or preserving historical artifacts, understanding the price and features of these machines ensures you make an informed investment that meets your needs.