Laser Rust Cleaning: The Future of Rust Removal

Introduction: Revolutionizing Rust Removal with Laser Technology

Rust—a relentless enemy of metal surfaces—compromises structural integrity, reduces efficiency, and diminishes aesthetics. Traditional methods such as sandblasting, chemical treatments, and manual grinding often create environmental hazards, increase labor costs, and risk damaging the base material.

Now, industries are turning to laser rust cleaning, an innovative, non-abrasive, chemical-free, and highly precise method that removes rust without surface damage. This game-changing technology is reshaping automotive restoration, industrial maintenance, aerospace engineering, and historic conservation.

How does laser rust cleaning work? Is it cost-effective? And what industries benefit the most? This guide will explore the science, benefits, applications, and costs of laser rust removal to help you determine if it’s the right solution for your needs.

1. What is Laser Rust Cleaning?

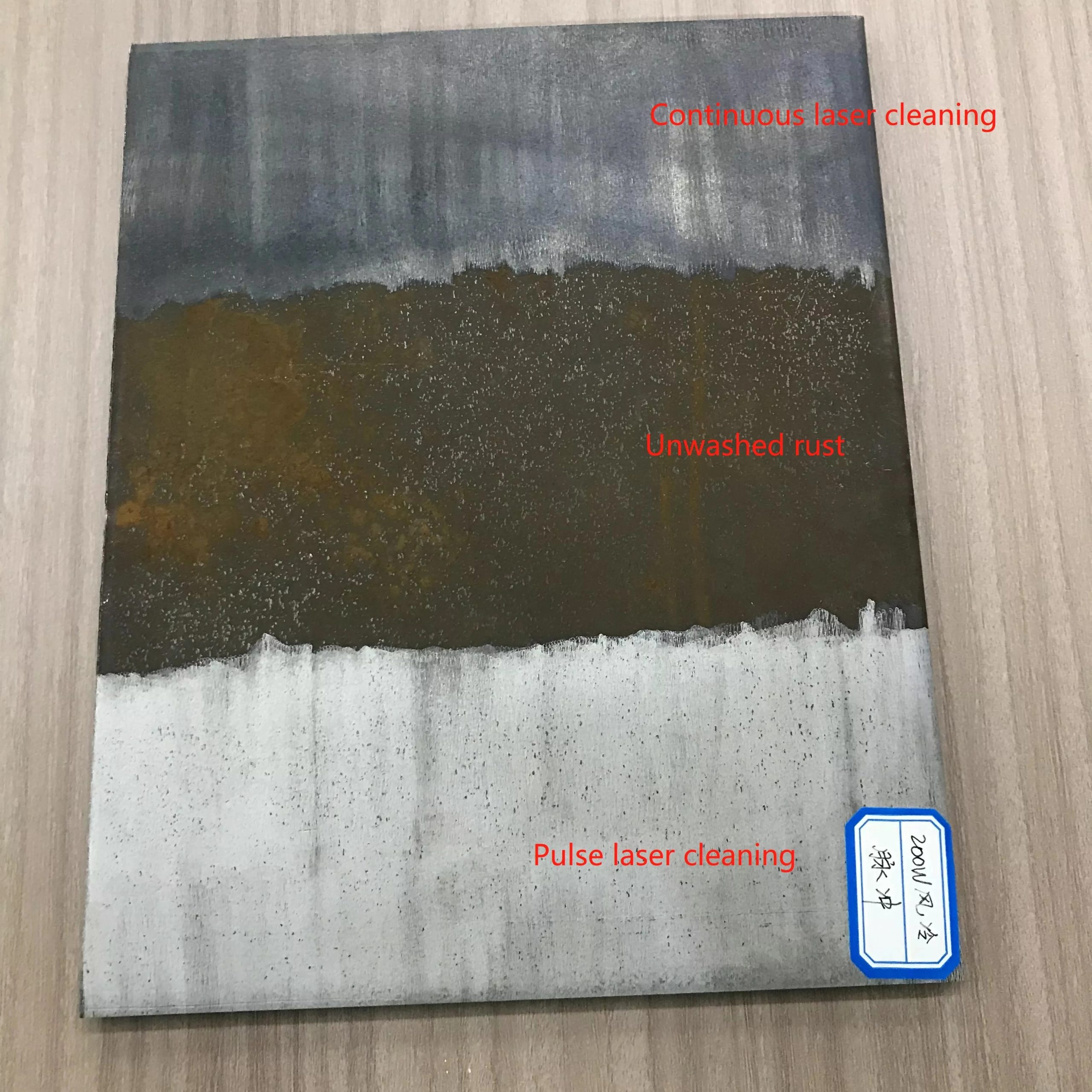

Laser rust cleaning is a cutting-edge technique that removes corrosion, oxidation, and contaminants using high-intensity laser pulses. Unlike abrasive blasting or chemical etching, this method ensures precision without damaging the underlying material.

How Does Laser Rust Removal Work?

1. A focused laser beam is directed at the rusted surface.

2. The rust absorbs the laser energy, causing rapid heating and vaporization.

3. The oxide layer breaks apart, turning into fine dust.

4. The cleaned surface remains undamaged and ready for further processing.

This dry, non-contact, and residue-free process is ideal for industries that require high precision and environmental safety.

2. Why Choose Laser Rust Cleaning Over Traditional Methods?

Rust removal is essential in manufacturing, automotive, construction, and marine industries. But conventional methods have significant drawbacks.

Comparing Laser Rust Cleaning with Traditional Techniques

| Feature | Laser Rust Cleaning | Sandblasting | Chemical Treatments |

|---|---|---|---|

| Surface Protection | No material loss | Can erode surface | May cause corrosion |

| Environmental Impact | No chemicals, no waste | Generates dust & debris | Toxic waste disposal needed |

| Precision | High accuracy | Less control | Uneven application |

| Labor & Safety | Minimal effort, safe | High dust exposure | Requires protective gear |

| Maintenance Costs | Low, no consumables | Frequent equipment wear | Recurring chemical costs |

Laser technology offers a superior alternative, reducing waste, operational costs, and safety risks.

3. Key Applications of Laser Rust Cleaning

From industrial machinery to heritage restoration, laser rust cleaning is transforming multiple industries by providing precise, eco-friendly solutions.

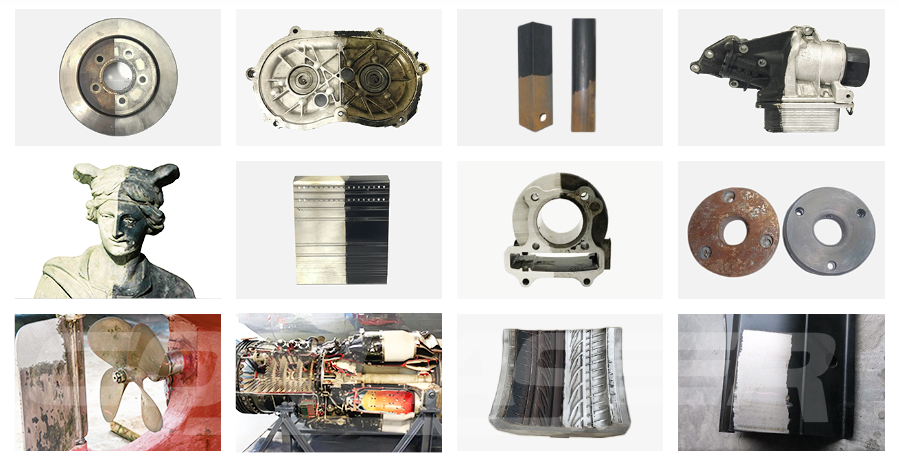

1. Automotive & Aerospace

• Removes rust from classic car frames, aircraft parts, and engine components.

• Prepares metal surfaces for repainting or weldingwithout abrasives.

• Cleans brake discs, exhaust systems, and structural components.

2. Manufacturing & Metal Processing

• Eliminates corrosion on steel, aluminum, and cast iron

• Cleans welding seams, molds, and industrial machinery.

• Improves adhesion for coatings, plating, and bonding applications.

3. Shipbuilding & Marine Industry

• Removes rust from ship hulls, pipelines, and offshore structures.

• Cleans propellers, fuel tanks, and naval equipmentwithout damaging surfaces.

• Reduces downtime for marine maintenance and repairs.

4. Construction & Infrastructure Maintenance

• Cleans bridges, rail tracks, and structural beams.

• Restores historical monuments, statues, and architectural details.

• Removes graffiti, oxidation, and weather damagewithout harsh chemicals.

5. Electronics & Precision Engineering

• Cleans microelectronics, circuit boards, and semiconductor components.

• Removes thin oxide layers and contaminantswithout static discharge risks.

Laser rust cleaning is a versatile and efficient solution for preserving, restoring, and maintaining metal surfaces.

4. How Much Does Laser Rust Cleaning Cost?

The cost of a laser rust cleaner depends on power output, automation level, and application needs.

Price Breakdown by Laser Power

| Power Output | Price Range (USD) | Best Use Cases |

|---|---|---|

| 50W – 100W | $3,000 – $10,000 | Light rust, small tools, delicate parts |

| 200W – 300W | $10,000 – $30,000 | Automotive parts, general metal cleaning |

| 500W – 1000W | $30,000 – $70,000 | Industrial applications, heavy rust removal |

| 1500W+ | $70,000+ | Shipbuilding, large-scale infrastructure |

What Affects the Cost?

1. Laser Type:Fiber lasers are more efficient and durable than CO2 lasers.

2. Cooling System:Air-cooled lasers are cheaper, while water-cooled systems support continuous operation.

3. Automation & AI Features:Smart, robotic systems increase productivity but raise costs.

4. Portability:Handheld units are more affordable, while fully automated setups are expensive.

Despite the upfront investment, laser rust cleaning reduces maintenance costs, labor expenses, and consumable usage, leading to long-term savings.

5. The Long-Term Savings & Benefits of Laser Rust Cleaning

1. Eliminates Consumable Costs

• No need for sandblasting media, chemicals, or abrasives.

• Reduces waste disposal fees and material costs.

2. Increases Equipment Lifespan

• Protects metal surfaces from excessive wear and tear.

• Prevents further oxidation and corrosion damage.

3. Reduces Labor Costs & Time

• Cleans faster than traditional methods, reducing manual effort.

• Requires minimal trainingfor operators.

4. Environmentally Friendly & Regulatory Compliance

• Meets eco-friendly manufacturing standards.

• Reduces exposure to hazardous materials and workplace risks.

Industries that adopt laser rust cleaning see higher productivity, lower operational costs, and improved safety standards.

6. How to Choose the Right Laser Rust Cleaner

Selecting the best laser rust cleaning system depends on:

1. Power Requirements:

° 50W – 100W:Best for light-duty rust removal and precision parts.

° 200W – 300W:Ideal for automotive, industrial, and general manufacturing.

° 500W+:Recommended for heavy-duty applications like shipbuilding and infrastructure.

2.Portability vs. Fixed Installations:

° Handheld models offer flexibility for on-site cleaning.

° Automated laser cleaning systemsintegrate with production lines.

3.Cooling Mechanism:

° Air-cooled systemsfor intermittent use.

° Water-cooled systemsfor continuous industrial operation.

4.Budget vs. Long-Term ROI:

° Budget vs. Long-Term ROI:

By choosing the right power level, cooling method, and automation features, businesses can maximize efficiency and cost-effectiveness.

Final Thoughts: The Future of Rust Removal is Laser Technology

Rust removal is no longer a time-consuming, wasteful, or hazardous process. Laser rust cleaning offers a fast, eco-friendly, and highly precise solution for industrial maintenance, automotive restoration, and infrastructure preservation.

As technology advances, costs will decrease, efficiency will improve, and adoption will expand—making laser rust cleaning the standard for modern rust removal.