Laser Deep Cleaning: Revolutionizing Precision Surface Cleaning

Laser deep cleaning is changing the way industries approach surface preparation and restoration. Imagine a process so precise that it can remove microscopic layers of rust, paint, or contaminants without damaging the base material. No abrasives, no chemicals—just pure laser power for unmatched efficiency and sustainability. Whether in aerospace, automotive, or cultural restoration, laser deep cleaning stands at the forefront of innovation.

What Is Laser Deep Cleaning?

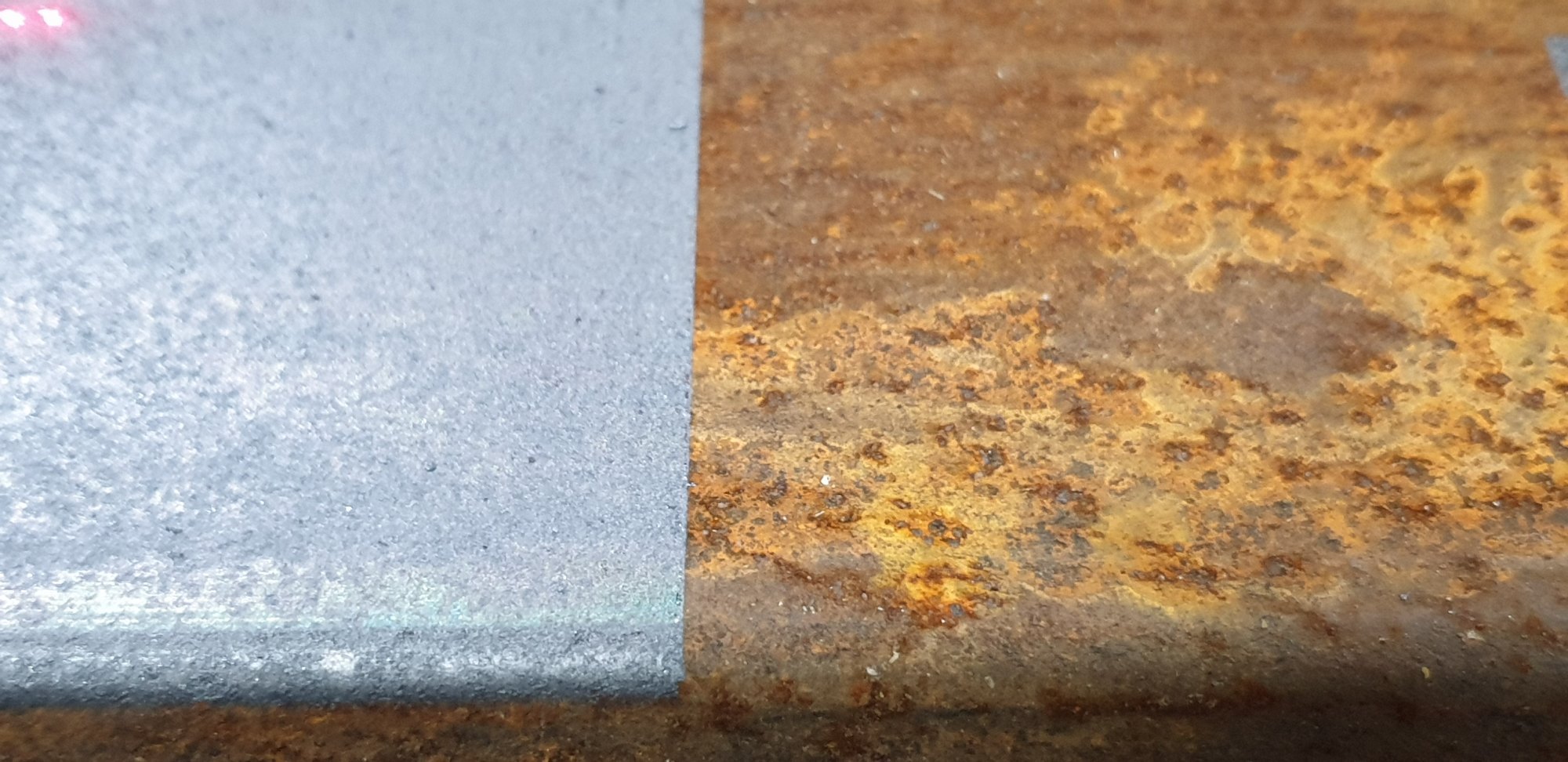

Laser deep cleaning is a non-contact surface treatment method that uses high-energy laser pulses to remove contaminants. This process, known as laser ablation, targets unwanted material layers while preserving the structural integrity of the base material.

Unlike traditional methods such as sandblasting or chemical stripping, laser deep cleaning leaves no residue or scratches, making it the superior choice for intricate or valuable surfaces.

How Laser Deep Cleaning Works

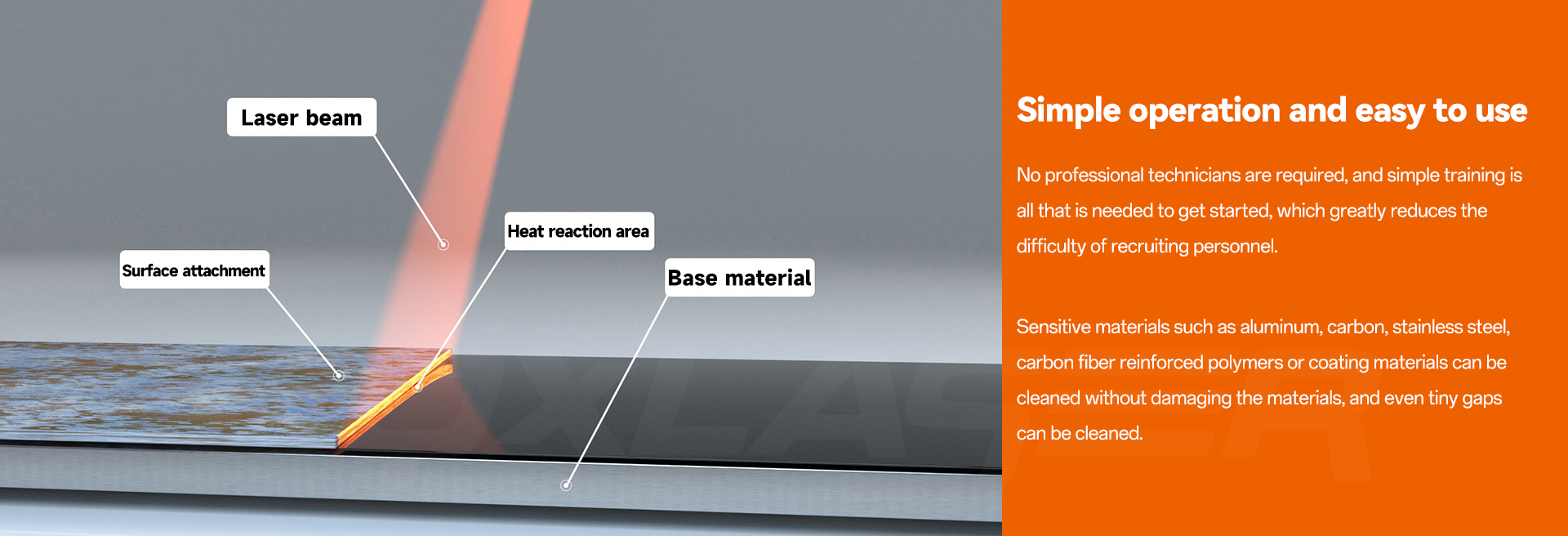

1. Laser Beam Emission: A high-energy laser beam is directed at the contaminated surface.

2. Selective Absorption: The contaminants absorb the energy, heating up and breaking apart.

3. Vaporization: The unwanted material is converted into gas or dust and removed, revealing a clean surface.

This method offers unparalleled control, with adjustable power settings for cleaning everything from delicate objects to industrial machinery.

Key Benefits of Laser Deep Cleaning

1. Eco-Friendly and Chemical-Free

Laser deep cleaning requires no chemical agents, making it an environmentally safe solution that minimizes waste and harmful emissions.

2. Non-Abrasive Cleaning

Unlike abrasive methods, laser cleaning does not scratch or erode the surface, preserving the original material.

3. Precision and Control

The laser beam can be fine-tuned to clean specific areas with pinpoint accuracy, making it ideal for detailed work.

4. Reduced Maintenance and Costs

Laser systems require minimal maintenance and eliminate the recurring cost of consumables like sand or solvents.

5. Versatile Application

From removing rust and paint to preparing surfaces for bonding or welding, laser deep cleaning has a broad range of industrial and commercial uses.

Applications of Laser Deep Cleaning

1. Automotive Restoration and Maintenance

Laser deep cleaning is used to remove rust, grease, and old coatings from car frames, engine parts, and suspension systems, preparing them for repainting or repairs.

2. Aerospace and Aviation

Aircraft components require precision cleaning to maintain safety and performance. Laser deep cleaning removes oxidation and surface contaminants without affecting the metal’s structural integrity.

3. Industrial Manufacturing

Factories use laser cleaning to maintain equipment, molds, and conveyor belts, reducing downtime and improving operational efficiency.

4. Marine and Shipbuilding

Laser technology effectively removes corrosion, salt deposits, and barnacles from ship hulls and offshore platforms, preparing surfaces for repairs or repainting.

5. Cultural Heritage Preservation

Museums and restoration experts use laser deep cleaning to remove dirt and deposits from historical artifacts and sculptures without damaging the original material.

Types of Laser Deep Cleaning Machines

1. Low-Power Machines (50W - 100W)

These machines are ideal for delicate surfaces and light cleaning tasks, such as removing thin layers of rust or soot.

2. Mid-Power Machines (200W - 500W)

Suitable for industrial use, mid-power systems balance precision and power for tasks like paint stripping and surface preparation.

3. High-Power Machines (1000W and Above)

Designed for heavy-duty applications, high-power machines remove thick rust and industrial coatings from large metal surfaces.

Key Features to Look for in a Laser Deep Cleaning Machine

1. Adjustable Power Settings

The ability to control power output allows you to clean both delicate and durable surfaces with ease.

2. Efficient Cooling System

A reliable cooling system, whether air-cooled or water-cooled, ensures that the machine operates efficiently during extended cleaning sessions.

3. Portable Design

Handheld and portable models offer flexibility for on-site applications and fieldwork.

4. Safety Features

Look for machines with built-in safety measures, such as emergency stop buttons, protective shielding, and automatic shutdowns.

5. User-Friendly Interface

An intuitive control panel with pre-programmed settings simplifies operation and enhances accuracy.

Price Ranges for Laser Deep Cleaning Machines

The price of a laser deep cleaning machine depends on its power, features, and included accessories. Here’s a general breakdown:

• Entry-Level Models (50W – 100W): $8,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-End Industrial Models (1000W and Above): $50,000+

Additional costs may include shipping fees, optional attachments, and extended warranty plans.

Maintenance Tips for Laser Deep Cleaning Machines

To ensure optimal performance and extend the lifespan of your machine:

1. Regularly Clean the Lens: Dust and debris on the lens can affect laser accuracy.

2. Check the Cooling System: Ensure that air or water cooling components are free from blockages.

3. Follow Calibration Guidelines: Periodically calibrate the machine for consistent performance.

4. Store Properly: Keep the machine in a dry, temperature-controlled space when not in use.

Innovations in Laser Deep Cleaning Technology

Recent advancements have made laser deep cleaning systems more compact, energy-efficient, and user-friendly. Smart sensors now allow some machines to adjust laser intensity automatically based on the surface material and contamination level. Additionally, green laser technology is being explored to improve performance on non-metal surfaces, further expanding the range of applications.

Comparing Laser Deep Cleaning to Traditional Methods

1. Time Efficiency

Laser deep cleaning significantly reduces cleaning times compared to manual scraping and chemical treatments.

2. Safety and Environmental Impact

With no harmful chemicals or dust particles, laser cleaning offers a safer work environment and a reduced environmental footprint.

3. Precision and Versatility

Unlike abrasive blasting, laser cleaning targets specific areas with incredible precision, making it ideal for detailed and intricate work.

How to Choose the Right Laser Deep Cleaning Machine

When selecting a laser deep cleaning system, consider these factors:

• Type of Surface: Is it metal, stone, or another material?

• Frequency of Use: Will the machine be used occasionally or for continuous operation?

• Power Requirements: Choose a power level that matches your cleaning needs.

• Portability: Do you need a stationary unit or a portable model for fieldwork?

• Budget: Determine your budget for both initial investment and long-term maintenance.

Answering these questions will help you choose a machine that fits your specific cleaning needs and operational goals.

Laser deep cleaning offers unmatched precision, sustainability, and efficiency for a wide range of industries. By investing in the right system and understanding its features, you can optimize your cleaning process, save time, and enhance overall productivity. This innovative technology is redefining surface preparation and maintenance, setting a new standard for safe and effective cleaning.