Laser Cleaning System: The Future of Industrial Surface Cleaning

Introduction: Why the Laser Cleaning System is Transforming Industries

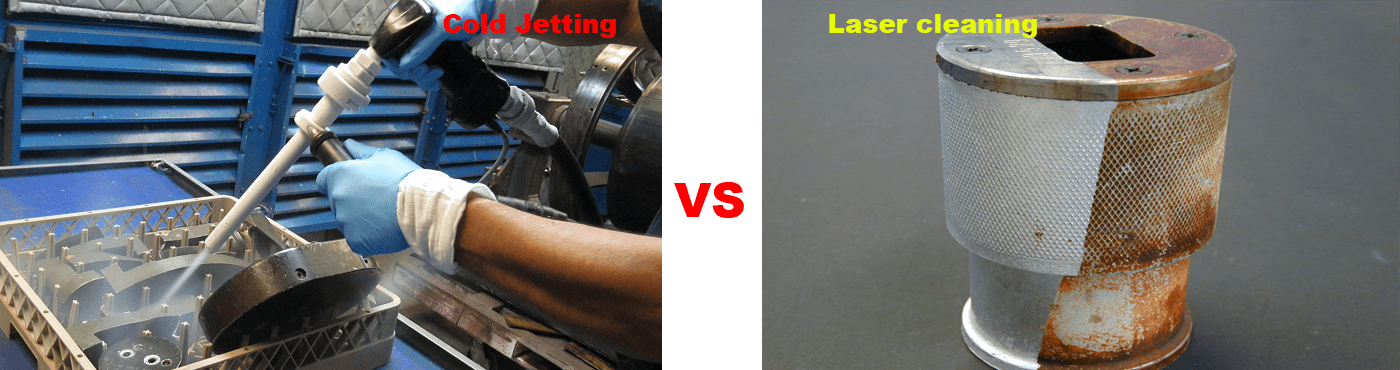

For decades, industries have relied on abrasive blasting, chemical solvents, and manual scrubbing to remove rust, paint, grease, and surface contaminants. While these methods have been the standard, they come with drawbacks: high labor costs, environmental hazards, and potential damage to base materials.

Now, a new era of surface treatment is here: laser cleaning systems. These advanced machines offer a non-contact, eco-friendly, and highly efficient solution for surface cleaning, making them an essential tool in manufacturing, restoration, and maintenance.

How does a laser cleaning system work? What makes it better than traditional cleaning methods? And is it worth the investment? In this guide, we’ll explore the technology, applications, pricing, and benefits of laser cleaning systems.

1. What is a Laser Cleaning System?

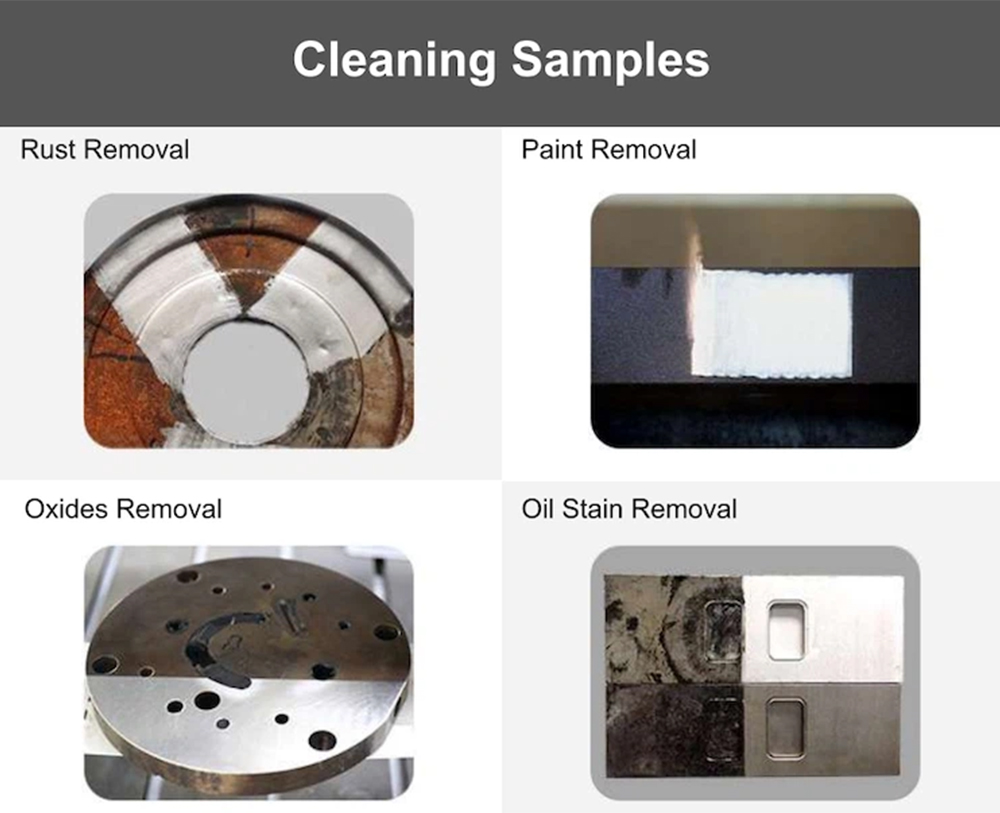

A laser cleaning system is a high-tech device that uses intense laser pulses to remove unwanted materials from surfaces. By applying high-energy laser beams, the system vaporizes or dislodges contaminants such as rust, paint, oxides, and grease—without damaging the underlying material.

How Does Laser Cleaning Work?

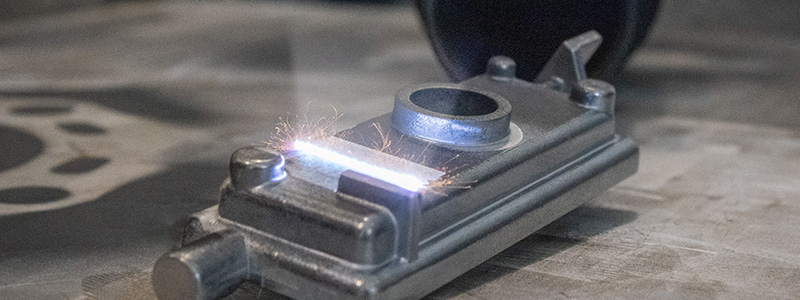

1. A laser beamis directed at the contaminated surface.

2. The contaminant layer absorbs the laser energy, causing it to evaporate or break apart.

3. The base material remains untouched, as the laser precisely targets the top layer.

4. The debris is either dispersed into the air or removed using a vacuum or air blower.

This non-abrasive, eco-friendly method is becoming the go-to solution for industries requiring precision and sustainability.

2. Why Choose a Laser Cleaning System Over Traditional Methods?

When compared to conventional surface cleaning techniques, laser technology stands out for several reasons:

1. Non-Contact & Non-Damaging

• Unlike sandblasting or grinding, laser cleaning does not wear downthe material.

• Ideal for delicate components, ensuring surface integrity.

2. Eco-Friendly & Chemical-Free

• No need for hazardous solvents or abrasive media.

• Reduces waste disposal costsand environmental impact.

3. High Precision & Selective Cleaning

• Can target specific areaswithout affecting surrounding materials.

• Suitable for industrial restoration, precision maintenance, and historic conservation.

4. Minimal Maintenance & Operating Costs

• No consumables (abrasives, chemicals) required.

• Reduces labor-intensive cleaning processesand improves productivity.

5. Safer Work Environment

• Eliminates exposure to toxic chemicals and airborne dust particles.

• Requires only basic protective gearfor operator safety.

With these benefits, a laser cleaning system offers a cost-effective, sustainable, and high-performance alternative to conventional cleaning methods.

3. Applications of Laser Cleaning Systems

Laser cleaning technology is transforming multiple industries by providing efficient and precise surface cleaning solutions.

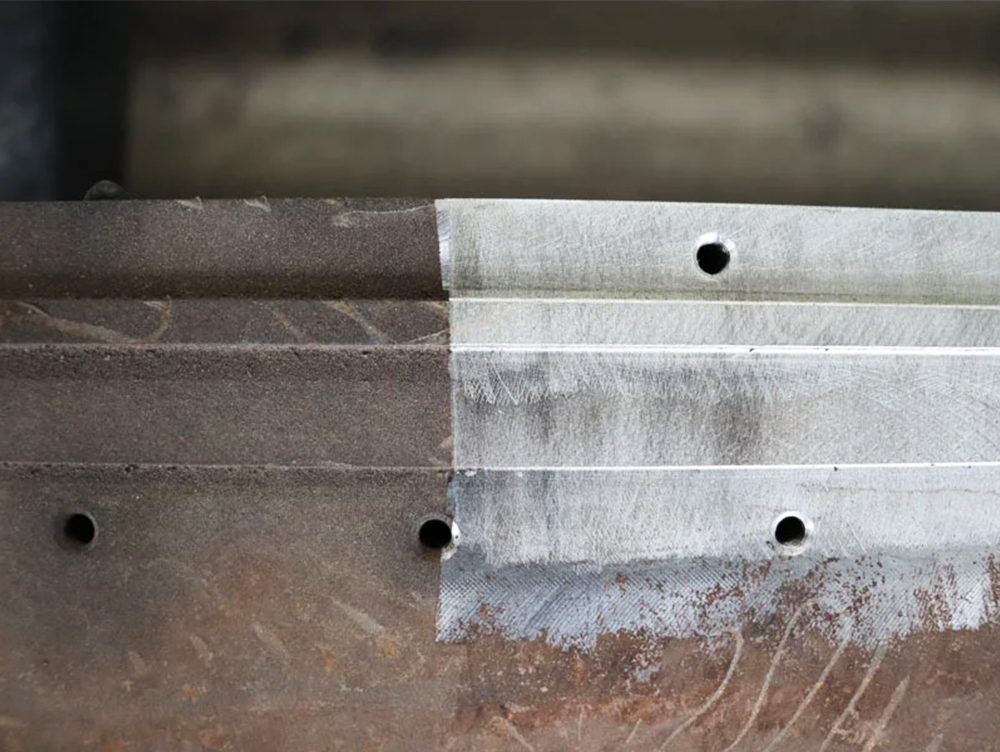

Manufacturing & Metal Processing

• Removes oxides, coatings, and greasefrom metal parts before welding or painting.

• Cleans industrial tools and machineryfor maintenance.

Automotive & Aerospace Industry

• Restores classic car frameswithout harming the metal.

• Cleans engine parts, turbines, and aircraft components.

• Prepares metal surfaces for bonding or coating applications.

Heritage & Artwork Restoration

• Gently removes dirt, soot, and pollutantsfrom stone, wood, and metal surfaces.

• Preserves historic sculptures, buildings, and artifacts.

Shipbuilding & Marine Industry

• Eliminates corrosion and biofoulingfrom ship hulls and offshore structures.

• Cleans valves, pipelines, and mechanical components without abrasive damage.

Electronics & Semiconductor Industry

• Cleans delicate microelectronic componentswithout static discharge.

• Removes thin oxide layersfrom precision parts.

The versatility of laser cleaning systems makes them a valuable asset in various sectors.

4. How Much Does a Laser Cleaning System Cost?

The price of a laser cleaning system depends on several factors, including power level, automation, and cooling systems.

Price Breakdown by Power Level

| Power Output | Price Range (USD) | Best Use Cases |

|---|---|---|

| 50W – 100W | $3,000 – $10,000 | Light cleaning, electronics, small parts |

| 200W – 300W | $10,000 – $30,000 | Industrial rust removal, automotive parts |

| 500W – 1000W | $30,000 – $70,000 | Heavy-duty cleaning, aerospace, shipbuilding |

| 1500W+ | $70,000+ | Large-scale industrial applications |

Factors Influencing Cost

1. Laser Type:Fiber lasers are more efficient and durable than CO2 lasers.

2. Cooling System:Air-cooled lasers are cheaper, while water-cooled systems support high-power applications.

3. Automation & AI Features:Smart laser systems increase cost but improve efficiency.

4. Portability:Handheld models cost less, while fully automated solutions require higher investment.

Although initial costs can be significant, the long-term savings on maintenance, labor, and consumables make laser cleaning a profitable investment.

5. Long-Term Savings & Cost Benefits of Laser Cleaning Systems

1. Eliminates Consumable Costs

• No need for sandblasting materials, chemicals, or abrasives.

• Cuts down on storage and disposal expenses.

2. Reduces Labor Costs

• Faster cleaning speeds reduce manual labor time.

• Automated systems eliminate the need for constant supervision.

3. Extends Equipment Lifespan

• Prevents surface wear and material degradation.

• Reduces the frequency of part replacements and repairs.

4. Environmentally Friendly & Compliant

• Meets strict environmental regulationsby eliminating toxic waste.

• Reduces airborne contaminants and workplace hazards.

By switching to a laser cleaning system, businesses can achieve significant cost savings while improving efficiency and safety.

6. Choosing the Right Laser Cleaning System for Your Needs

When selecting a laser cleaning system, consider:

1. Power Output:

° 50W – 100W: Light-duty cleaning.

° 200W – 300W: Industrial rust removal.

° 500W – 1000W:Heavy-duty cleaning.

2. Portability vs. Fixed Installations:

° Handheld systemsfor on-site flexibility.

° Automated unitsfor production-line cleaning.

3. Cooling Mechanism:

° Air-cooled systemsfor short-duration tasks.

° Water-cooled systemsfor continuous use.

4. Budget vs. Performance:

° A higher initial costoften means greater long-term ROI.

Matching the right system to your needs ensures maximum efficiency and cost-effectiveness.

Final Thoughts: The Future of Surface Cleaning with Laser Technology

A laser cleaning system is more than just an advanced cleaning tool—it’s an investment in efficiency, sustainability, and precision. From industrial maintenance to historic preservation, laser technology is reshaping how industries handle surface cleaning and restoration.

As laser technology continues to advance, costs will decrease, automation will improve, and efficiency will reach new heights—making laser cleaning systems the future of industrial surface treatment.