Laser Cleaning Machines: The Future of Precision Surface Treatment

In the world of industrial cleaning, laser cleaning machines have emerged as game changers. Imagine a technology that effortlessly removes rust, paint, and dirt with pinpoint accuracy—without harmful chemicals or abrasive force. This is the power of laser cleaning, where science meets precision and efficiency.

Whether you’re a manufacturer maintaining expensive equipment or a restorer preserving delicate artifacts, laser cleaning machines offer unmatched performance and sustainability.

What Are Laser Cleaning Machines?

Laser cleaning machines use concentrated beams of light to remove surface contaminants without damaging the underlying material. This non-contact process, known as laser ablation, heats and vaporizes contaminants such as rust, paint, and dirt. The result? A clean, restored surface without the need for scrubbing or sanding.

How Do Laser Cleaning Machines Work?

1.Light Pulse Generation: A laser beam is generated and focused on the target surface.

2.Selective Absorption: The contaminant layer absorbs the laser energy, causing it to break down.

3.Vaporization and Dusting: The broken particles turn into gas or fine dust, leaving a clean surface behind.

This process allows for controlled, precise cleaning that can be fine-tuned for different materials and contaminant layers.

Key Benefits of Laser Cleaning Machines

1. Eco-Friendly and Chemical-Free

Laser cleaning machines eliminate the need for toxic chemicals and abrasives, making them an environmentally responsible choice.

2. Non-Abrasive Surface Cleaning

Unlike sandblasting or grinding, laser cleaning preserves the structural integrity of the base material, making it ideal for delicate or high-value components.

3. Precision and Control

The intensity and focus of the laser can be adjusted, allowing for highly targeted cleaning of complex surfaces.

4. Cost-Effective Over Time

Although the initial investment may be high, the low maintenance and operating costs of laser cleaning machines result in long-term savings.

5. Minimal Waste and Residue

Since the contaminants are vaporized, there’s minimal waste to manage, reducing post-cleaning tasks.

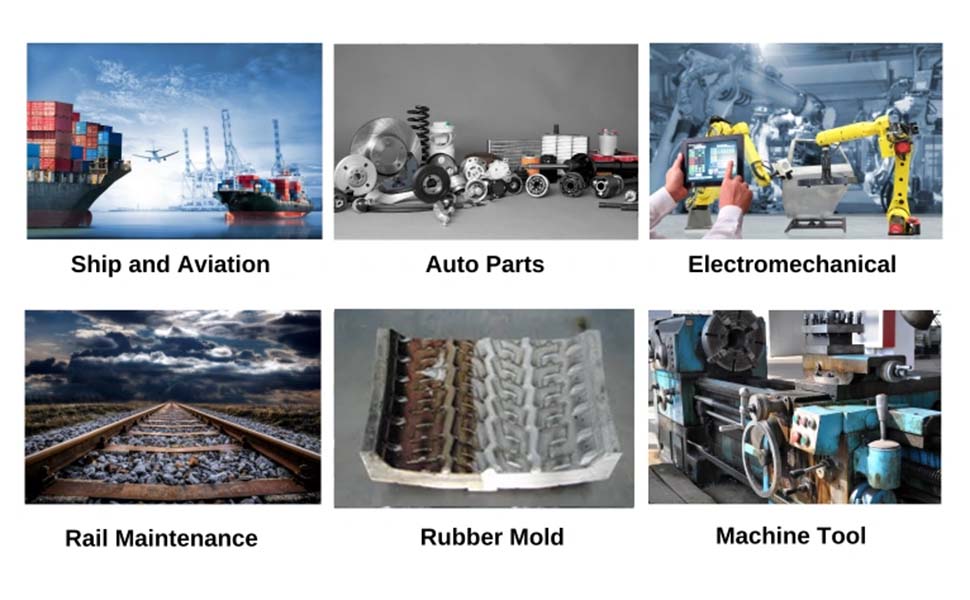

Applications of Laser Cleaning Machines

1. Automotive Industry

Laser cleaning machines remove rust and paint from car frames, engine parts, and molds, enhancing the precision of surface preparation.

2. Aerospace Maintenance

In aerospace, precision is key. Laser cleaning effectively removes oxidation and surface debris without introducing heat stress or weakening metal structures.

3. Manufacturing and Industrial Cleaning

Factories use laser cleaning machines to maintain equipment, molds, and conveyors, reducing downtime and prolonging machinery lifespan.

4. Cultural Heritage Preservation

Conservation experts use laser cleaning to restore sculptures, monuments, and paintings, removing unwanted layers without damaging the original material.

5. Shipbuilding and Marine Applications

Laser cleaning machines remove salt residue and rust from ship hulls and offshore platforms, preparing surfaces for repainting or repairs.

Types of Laser Cleaning Machines

1. Handheld Laser Cleaning Machines

Portable and user-friendly, these machines are perfect for on-site maintenance and mobile cleaning tasks.

2. Stationary Laser Cleaning Systems

Ideal for industrial settings, these machines are fixed units that provide consistent cleaning power for large-scale applications.

3. Automated Laser Cleaning Systems

Integrated with robotic arms, these machines offer precision and efficiency for automated production lines.

Factors to Consider When Choosing a Laser Cleaning Machine

1. Laser Power Output

• Low Power (50W – 100W): Suitable for light rust and paint removal.

• Medium Power (200W – 500W): Ideal for industrial maintenance.

• High Power (1000W and above): Best for large-scale cleaning and deep contaminant layers.

2. Cooling System

Machines with water-cooled systems handle longer cleaning sessions more effectively than air-cooled models.

3. Portability

For mobile operations, lightweight, handheld models are more practical.

4. Automation and Smart Features

Advanced systems with pre-programmed settings, touchscreens, and automation increase ease of use but may raise the overall price.

5. Safety Features

Look for features such as emergency shut-offs, protective shielding, and automatic adjustments to ensure safe operation.

Typical Price Ranges for Laser Cleaning Machines

1.Entry-Level Models(50W – 100W): $8,000 – $20,000

2.Mid-Range Systems(200W – 500W): $25,000 – $50,000

3.High-End Industrial Models(1000W and above): $60,000 – $100,000+

These prices may vary based on brand, features, and additional accessories.

Maintenance Tips for Laser Cleaning Machines

1.Regularly Clean the Lens: Prevent dust buildup on the laser lens to maintain accuracy.

2.Check the Cooling System: Ensure the water or air cooling system is functioning properly to prevent overheating.

3.Inspect Fiber Cables: Damaged or dirty fiber cables can reduce the laser’s effectiveness.

4.Follow Firmware Updates: Keeping the machine’s software updated ensures optimal performance.

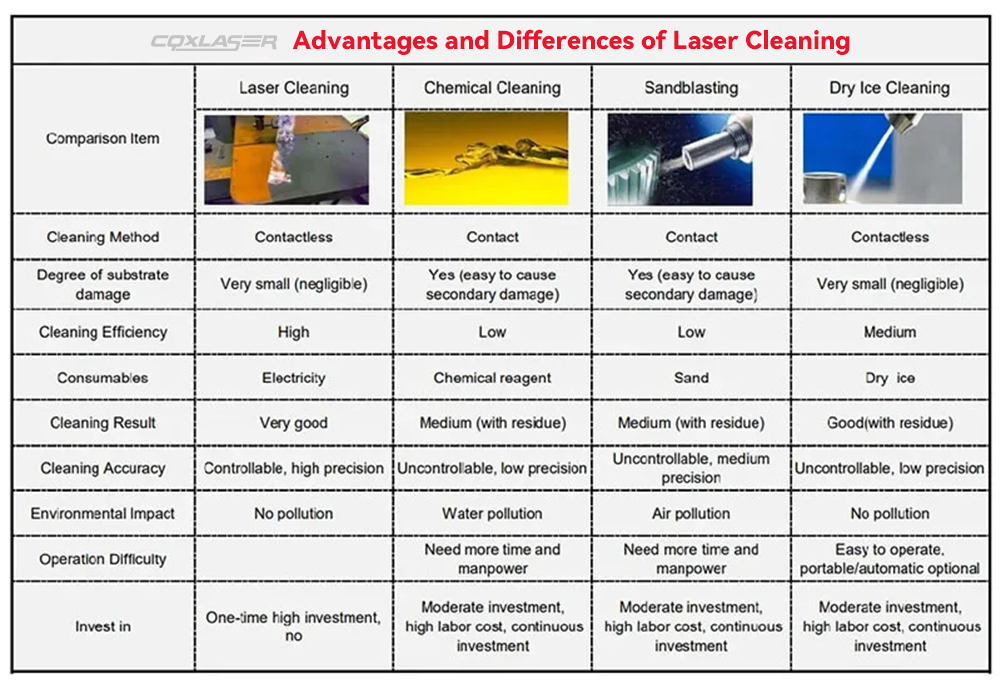

Advantages Over Traditional Cleaning Methods

1. Versatility Across Materials

Laser cleaning machines can clean metals, ceramics, composites, and even delicate surfaces like stone and glass.

2. Reduced Downtime

The speed and precision of laser cleaning minimize downtime, making it an ideal choice for industries with demanding schedules.

3. No Surface Residue

Unlike chemical cleaning, laser systems leave no sticky residues that require additional cleaning steps.

4. Safety for Operators

Laser cleaning systems include safety protocols to minimize exposure risks, making them safer for operators compared to traditional abrasive methods.

Innovations in Laser Cleaning Technology

Recent advancements have made laser cleaning machines more compact, energy-efficient, and affordable. Future developments may include AI-assisted systems that automatically detect contamination levels and adjust laser intensity for optimal performance. Green laser technology is also being explored to improve absorption rates for non-metallic surfaces.

How to Choose the Right Laser Cleaning Machine for Your Needs

Ask yourself the following questions:

• What type of contaminants will you be removing?

• How often will the machine be used?

• Do you need portability, or will the machine remain stationary?

• What is your budget for initial investment and long-term maintenance?

By answering these questions, you can narrow your options and select a laser cleaning machine that fits your operational needs.

Final Insights on Laser Cleaning Machines

Laser cleaning machines are reshaping industries with their precision, speed, and environmental benefits. Whether you’re removing rust from a ship’s hull or cleaning delicate museum artifacts, laser technology offers an unparalleled combination of power and safety. Understanding the features, costs, and applications of laser cleaning machines ensures that you make an informed choice that meets your specific cleaning challenges and business goals.

Investing in laser cleaning technology is not just a decision for today—it’s a step toward a more efficient, sustainable future.