Laser Cleaning Machine for Rust Removal: A Game-Changer in Surface Restoration

Introduction: Say Goodbye to Rust with Laser Cleaning Technology

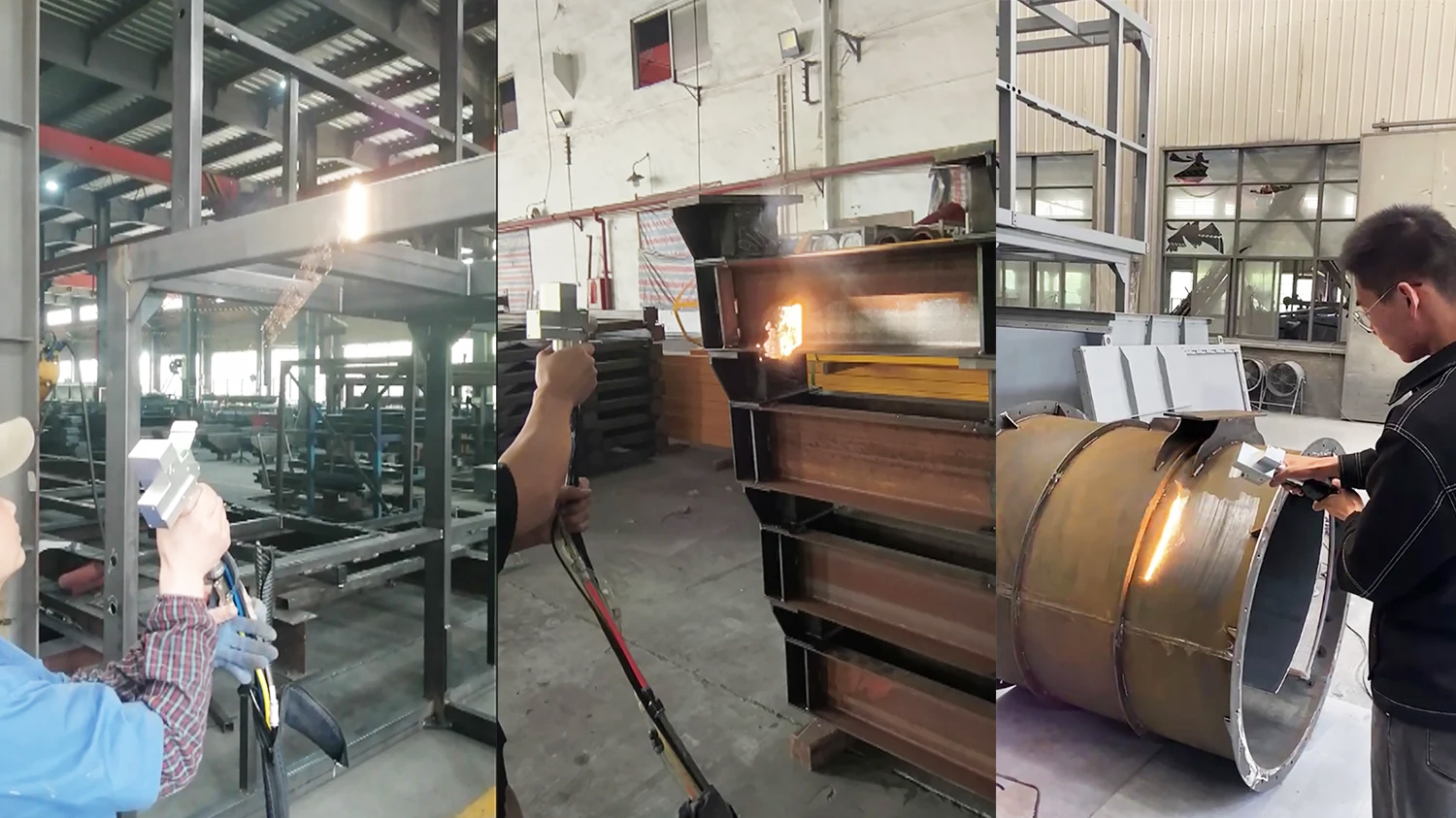

Rust—a persistent enemy of metal surfaces—has long plagued industries from manufacturing to automotive restoration. Traditional methods such as sandblasting, chemical treatments, and manual grinding often result in excessive labor, hazardous waste, and potential damage to base materials.

Now, a revolutionary solution is transforming rust removal: laser cleaning technology. Utilizing high-energy laser beams, this method offers precision, efficiency, and sustainability—without the mess and risks of conventional cleaning.

So, what makes a laser cleaning machine for rust removal the superior choice? This guide breaks down its working principles, benefits, cost considerations, and industrial applications to help you determine if it’s the right solution for your needs.

1. What is a Laser Cleaning Machine for Rust Removal?

A laser cleaning machine removes rust, paint, and contaminants from surfaces by directing focused laser pulses onto the affected area. The laser energy breaks down oxidation layers into fine particles, which are then evaporated or collected through suction.

How Does Laser Rust Removal Work?

1. The laser beamis directed at the rusted surface.

2. The rust absorbs the laser energy, causing rapid heating and vaporization.

3. The base material remains untouched, as the laser selectively targets oxide layers.

4. The rust debris is either dispersed into the air or removed using an extraction system.

Advantages of Laser Rust Removal vs. Traditional Methods

| Feature | Laser Cleaning | Traditional Methods |

|---|---|---|

| Surface Safety | Non-contact, no damage | Risk of abrasion or chemical reaction |

| Eco-Friendly | No chemicals, minimal waste | Uses harsh solvents, generates hazardous waste |

| Precision | Selective rust removal, no material loss | Often removes base metal along with rust |

| Speed & Efficiency | Fast cleaning with minimal labor | Time-consuming and requires multiple steps |

| Cost Over Time | Higher initial investment, lower maintenance costs | Lower upfront cost but recurring expenses |

Laser cleaning is becoming the preferred choice for businesses looking to eliminate rust effectively while preserving material integrity.

2. Key Applications of Laser Cleaning for Rust Removal

Laser rust removal is widely used across industrial and commercial sectors, delivering consistent, high-quality results in:

Automotive Industry

• Restoring classic car framesby removing rust without damaging paint

• Cleaning engine partsand metal components efficiently

• Preparing metal surfaces for welding or coating

Manufacturing & Metal Processing

• Removing rust from steel componentsbefore assembly

• Cleaning industrial molds and production equipment

• Enhancing adhesion for coatings, paints, and treatments

Shipbuilding & Marine Maintenance

• Removing corrosion from ship hulls and offshore structures

• Cleaning pipes, valves, and structural componentsin harsh environments

• Eliminating biofouling without damaging surfaces

Aerospace & Aviation

• Maintaining aircraft frames and turbine components

• Preventing material fatigue by removing rust and contaminants

• Enhancing the durability of metal partsin extreme conditions

Infrastructure & Construction

• Restoring bridges, rail tracks, and metal structures

• Cleaning rust from industrial machineryfor prolonged service life

• Removing oxidation from architectural metalwork

From large-scale industrial cleaning to precision restoration, laser technology offers a versatile solution for rust removal.

3. How Much Does a Laser Cleaning Machine for Rust Removal Cost?

The cost of a laser cleaning machine depends on factors such as power level, automation features, and cooling system requirements.

Laser Cleaning Machine Price Breakdown

| Power Level | Price Range (USD) | Best Use Cases |

|---|---|---|

| 50W – 100W | $3,000 – $10,000 | Light rust removal, delicate metal cleaning |

| 200W – 300W | $10,000 – $30,000 | Industrial rust cleaning, automotive restoration |

| 500W – 1000W | $30,000 – $70,000 | Heavy-duty rust removal, large-scale industrial applications |

| 1500W+ | $70,000+ | Shipbuilding, aerospace, high-performance cleaning |

What Influences the Price?

1. Power Output:Higher wattage delivers faster and deeper rust removal.

2. Laser Type:Fiber lasers are more durable and efficient than CO2 lasers.

3. Portability:Handheld models are more affordable, while automated systems cost more.

4. Cooling System:Water-cooled lasers handle longer operation times, increasing cost.

5. Software & Automation:AI-powered interfaces and robotic integration add value but raise pricing.

While initial costs may be high, long-term savings make laser cleaning a cost-effective investment.

4. The Long-Term Cost Benefits of Laser Rust Removal

1. Eliminates the Need for Consumables

• No sandblasting media, chemicals, or abrasive materials

• No recurring material costs—just electricity and occasional maintenance

2. Reduces Labor Costs

• Faster cleaning reduces manual effort

• Automated systemseliminate the need for multiple workers

3. Increases Equipment Lifespan

• Non-abrasive cleaning prevents surface wear

• Reduces the risk of material fatigue and corrosion

4. Compliance with Environmental Regulations

• No toxic chemical disposal fees

• Reduces workplace hazards, improving safety compliance

For companies seeking long-term efficiency, laser rust removal significantly lowers operational costs while improving performance.

5. Choosing the Right Laser Cleaning Machine for Your Needs

To find the best laser cleaning machine for rust removal, consider:

1. Power Requirements:

° Light rust → 50W – 100W

° Medium rust → 200W – 300W

° Heavy industrial rust → 500W+

2. Portability vs. Fixed Installations:

° Handheldfor on-site cleaning

° Automated systemsfor high-volume industrial use

3. Cooling Mechanism:

° Air-cooled for low-power systems

° Water-cooled for extended use & high power

4. Budget vs. Performance:

° Higher upfront cost = faster ROIdue to low maintenance

By matching power level, portability, and budget, businesses can select the most efficient laser rust removal system.

6. The Future of Laser Cleaning Technology

As industries prioritize sustainability and automation, laser cleaning technology continues to evolve.

Emerging Trends in Rust Removal Technology

• AI-Driven Laser Systems:Intelligent cleaning with adaptive laser settings

• More Affordable Compact Models:Expanding access for small businesses

• Higher Energy Efficiency:Lower operating costs with minimal power consumption

As innovation progresses, laser rust removal will become even more cost-effective and widely adopted.

Final Thoughts: The Best Rust Removal Solution for Modern Industries

Traditional rust removal methods fall short in efficiency, safety, and sustainability. A laser cleaning machine for rust removal offers a powerful, precise, and eco-friendly alternative, ensuring better results with lower long-term costs.

By investing in laser technology, businesses can reduce downtime, minimize waste, and achieve unmatched cleaning performance—a true game-changer in industrial surface treatment.