Laser Cleaner for Sale: Your Guide to Affordable and Efficient Surface Cleaning

In the search for precision, efficiency, and innovation, the laser cleaner for sale offers a powerful solution for industries and workshops alike. Imagine effortlessly removing rust, paint, and grime with a device that combines cutting-edge technology with eco-friendly performance. Whether you need a portable handheld unit or a high-power system for industrial use, the right laser cleaner can revolutionize your surface preparation process.

What Is a Laser Cleaner?

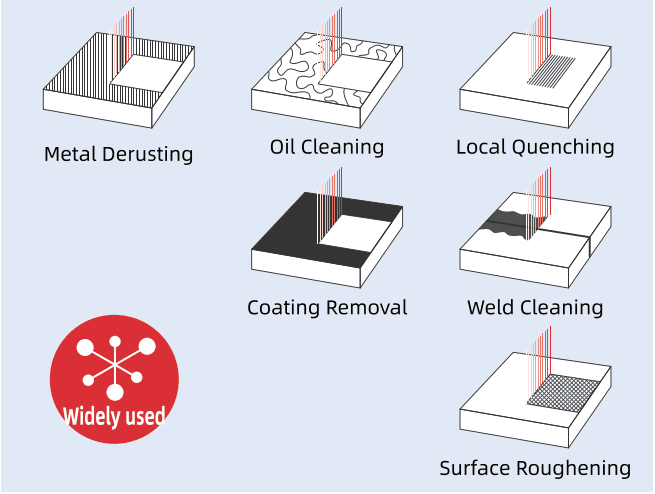

A laser cleaner is a device that uses high-energy laser beams to remove surface contaminants without harming the underlying material. This non-contact process, known as laser ablation, heats and vaporizes unwanted layers, such as rust, grease, and paint, converting them into dust or gas.

Why Look for a Laser Cleaner for Sale?

Investing in a laser cleaner is a long-term decision that improves cleaning efficiency while reducing costs associated with consumables, chemicals, and labor. When you find the right laser cleaner for sale, you gain access to:

• Non-abrasive cleaning that preserves valuable components

• Faster surface preparation with minimal setup

• Eco-friendly cleaning without harmful waste

How Laser Cleaners Work

1. Laser Beam Generation: The system emits pulses of concentrated light energy.

2. Absorption and Ablation: Contaminants absorb the energy, causing them to disintegrate.

3. Vaporization and Dusting: The debris is converted into vapor or dust particles, leaving a clean surface.

This precise cleaning process is highly customizable, allowing users to adjust power levels and beam focus for different tasks.

Benefits of Purchasing a Laser Cleaner

1. Chemical-Free and Eco-Friendly

Laser cleaning eliminates the need for chemical solvents, making it safer for workers and the environment.

2. Non-Destructive Surface Cleaning

Unlike abrasive methods, laser cleaners remove contaminants without scratching or weakening the base material.

3. Cost-Effective Maintenance

Although the initial investment may be significant, laser cleaners reduce costs over time by eliminating consumables like sand, cleaning pads, and chemicals.

4. Fast and Efficient

Laser cleaners reduce surface preparation time, enabling faster workflow and increased productivity.

5. Portable Options for On-Site Cleaning

Portable handheld laser cleaners provide the flexibility needed for fieldwork and on-site applications.

Common Applications for Laser Cleaners

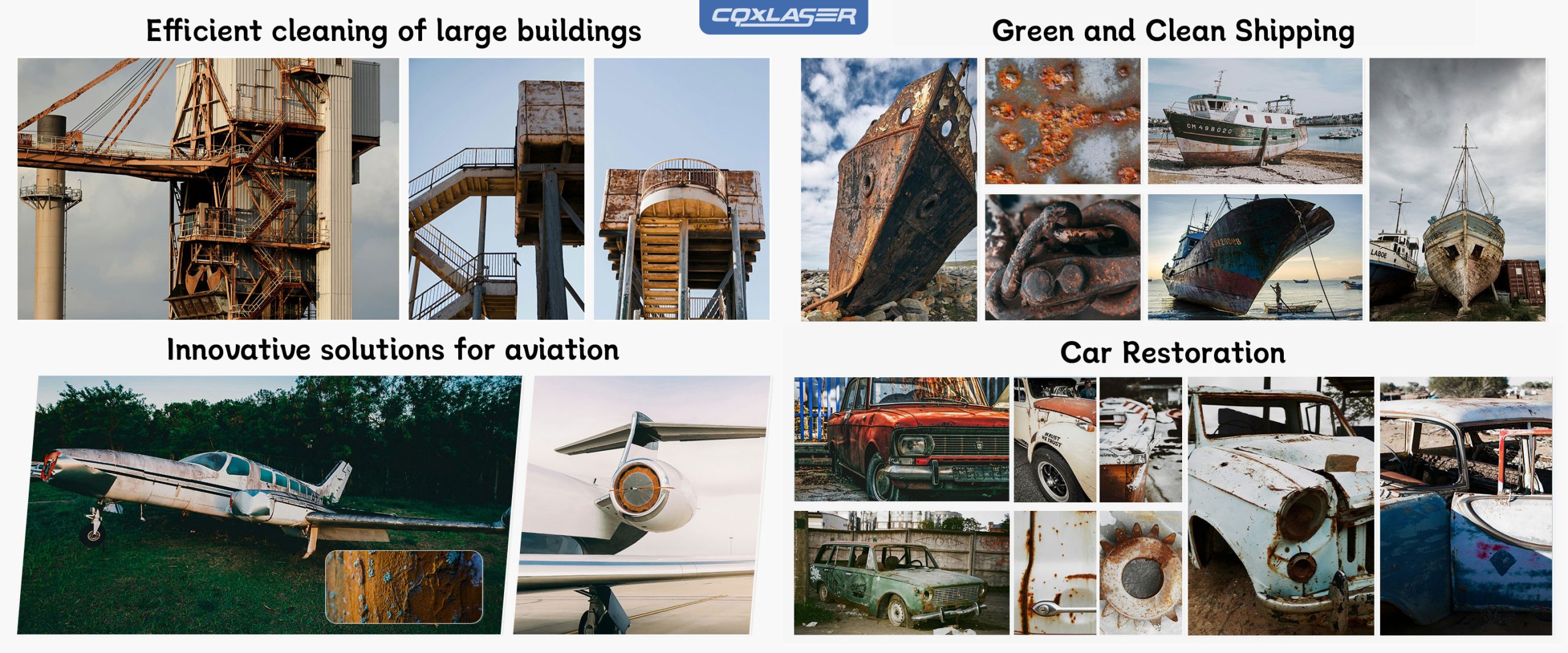

1. Automotive Industry

Laser cleaners are used to strip rust and paint from car frames, engine components, and chassis for restoration and repairs.

2. Industrial Maintenance

Factories use laser cleaners to maintain equipment, molds, and conveyor belts, minimizing downtime and prolonging the life of machinery.

3. Aerospace and Aviation

Laser cleaning ensures precision when removing oxidation, coatings, and contaminants from aircraft parts, where accuracy is crucial.

4. Marine and Shipbuilding

Portable laser cleaners remove corrosion and salt deposits from ship hulls, decks, and offshore structures.

5. Cultural Heritage Preservation

Restorers use laser cleaners to safely remove grime and deposits from historical artifacts, monuments, and sculptures.

Types of Laser Cleaners for Sale

1. Low-Power Laser Cleaners (50W - 100W)

Ideal for light cleaning tasks, such as surface preparation and rust removal from delicate parts.

2. Medium-Power Laser Cleaners (200W - 500W)

Suitable for industrial applications, these models balance portability and power.

3. High-Power Laser Cleaners (1000W and Above)

These machines handle heavy-duty cleaning tasks, such as deep rust and thick coating removal from large surfaces.

Key Features to Look for When Buying a Laser Cleaner

1. Adjustable Power Settings

Power settings allow users to customize the intensity of the laser for different cleaning tasks.

2. Efficient Cooling Systems

Air-cooled models are more compact, while water-cooled systems provide better thermal management for extended use.

3. Portability

Lightweight, ergonomic designs make handheld models easier to operate in different locations.

4. Safety Features

Ensure the laser cleaner includes safety measures such as emergency stop buttons, protective shields, and automatic shut-offs.

5. Smart Interfaces

User-friendly control panels with pre-set cleaning modes enhance convenience and accuracy.

Price Ranges for Laser Cleaners

The price of a laser cleaner depends on its specifications, power, and included features. Here’s a general overview:

• Entry-Level Models (50W – 100W): $7,000 – $15,000

• Mid-Range Models (200W – 500W): $20,000 – $40,000

• High-End Industrial Models (1000W and Above): $50,000+

Additional costs may include shipping, optional accessories, and extended warranties.

Maintenance Tips for Laser Cleaners

To ensure optimal performance and longevity:

1. Clean the Lens Regularly: Dust and debris on the lens can reduce laser accuracy.

2. Monitor the Cooling System: Check for blockages and leaks in water-cooled systems.

3. Avoid Overuse: Follow recommended operating times to prevent overheating.

4. Store Safely: Keep the machine in a dry, temperature-controlled environment.

Innovations in Laser Cleaning Technology

Recent advancements have made laser cleaners more efficient, affordable, and user-friendly. Newer models feature smart sensors that adjust laser intensity automatically based on the surface material and contamination level. Additionally, green laser technology is being developed to improve performance on non-metal surfaces.

Choosing the Right Laser Cleaner for Your Needs

When selecting a laser cleaner for sale, consider the following:

• What type of contaminants will you be removing?

• Do you need portability for mobile applications?

• How frequently will the

• What is your budget for initial investment and maintenance?

By answering these questions, you can narrow your search and choose a laser cleaner that aligns with your specific requirements.

Comparing Laser Cleaners to Traditional Cleaning Methods

1. Time Efficiency

Laser cleaning reduces cleaning times significantly compared to manual scraping and chemical stripping.

2. Safety and Environmental Impact

Unlike abrasive blasting, laser cleaning produces minimal waste and eliminates hazardous fumes.

3. Precision and Control

Laser cleaners can target specific areas with high precision, making them suitable for delicate and detailed work.

Finding the Best Laser Cleaner for Sale

Laser cleaners are a smart investment for anyone seeking efficient, non-destructive cleaning solutions. Whether you’re preparing metal for welding, restoring classic car parts, or maintaining industrial equipment, the right laser cleaner ensures fast, precise results. Explore your options, compare features, and choose a model that fits your needs to make the most of this innovative technology.

By understanding the benefits and selecting the right machine, you can transform your surface cleaning process and achieve superior results while saving time and resources.