Laser Cleaner Cost: How Much Should You Expect to Pay?

Introduction: The Price of Innovation in Cleaning Technology

Gone are the days of labor-intensive, chemical-heavy cleaning methods. Laser cleaning technology is revolutionizing industries, offering precision, efficiency, and eco-friendliness in surface treatment. But what about laser cleaner cost? Is it worth the investment, and what factors influence the price?

Whether you’re in manufacturing, restoration, or maintenance, understanding the cost of laser cleaners helps in making informed purchasing decisions. This guide dives into price ranges, influencing factors, and whether laser cleaning is a cost-effective solution for your business.

1. What is a Laser Cleaner and Why Does Cost Vary?

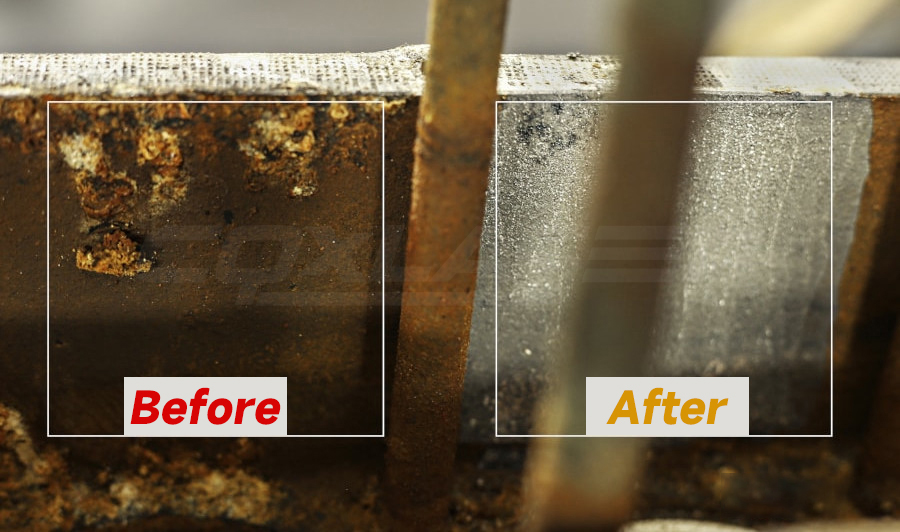

A laser cleaner is a high-tech device that uses pulsed laser beams to remove contaminants, rust, paint, and residues from surfaces. Unlike traditional cleaning techniques that rely on abrasives or chemicals, laser cleaning is precise, safe, and non-damaging to the base material.

Why Does the Cost of a Laser Cleaner Vary?

Several factors influence the price of laser cleaning machines, including:

• Laser Power (Wattage):Higher wattage provides faster and deeper cleaning, but increases cost.

• Laser Type:Fiber lasers are generally more efficient but come at a premium.

• Cooling System:Air-cooled systems are more affordable, while water-cooled models offer superior performance.

• Automation Features:Advanced models with robotic integration and AI-enhanced controls cost more.

• Brand Reputation & After-Sales Support:Reliable service and warranty contribute to long-term cost-effectiveness.

Understanding these factors ensures you’re not overpaying or selecting a system that doesn’t match your needs.

2. Laser Cleaner Cost Breakdown by Power Level

The cost of a laser cleaner depends largely on its power output, which determines its cleaning speed and application range. Below is an estimated price breakdown based on industry standards:

| Laser Power (Wattage) | Price Range (USD) | Best Suited For |

|---|---|---|

| 50W – 100W | $3,000 – $10,000 | Light-duty cleaning, small metal parts, delicate surfaces |

| 200W – 300W | $10,000 – $30,000 | Moderate rust, paint removal, industrial use |

| 500W – 1000W | $30,000 – $70,000 | Heavy-duty industrial cleaning, thick coatings |

| 1500W+ | $70,000+ | Large-scale manufacturing, shipbuilding, aerospace applications |

Understanding the Price vs. Performance Balance

Lower-wattage models may suffice for small-scale cleaning tasks, while industrial applications require high-power machines for maximum efficiency.

3. Hidden Costs & Long-Term Savings of Laser Cleaners

While the initial cost of a laser cleaner might seem high, the long-term savings justify the investment.

Hidden Costs to Consider

• Maintenance & Repairs:High-quality models require minimal upkeep, but repairs can be costly if components fail.

• Training & Safety Gear:Operators need proper training, and laser safety gear might be required.

• Power Consumption:Higher-wattage models consume more energy, but efficiency can offset costs.

Long-Term Cost Benefits

• No Consumables:Unlike sandblasting or chemical cleaning, laser cleaning requires no ongoing materials.

• Labor Savings:Faster cleaning means lower labor costs over time.

• Reduced Waste Disposal Fees:No hazardous chemicals mean lower environmental compliance costs.

These benefits make laser cleaning a cost-effective solution for industries looking to minimize operational expenses.

4. Is a Laser Cleaner Worth the Investment?

Determining whether the cost of a laser cleaner aligns with your needs depends on several key factors:

When Laser Cleaning is a Smart Investment

• Your business involves frequent rust, paint, or residue removal.

• You require precision cleaning without damaging base materials.

• Long-term cost savings outweigh the upfront price.

• Environmental regulations make traditional cleaning methods costly.

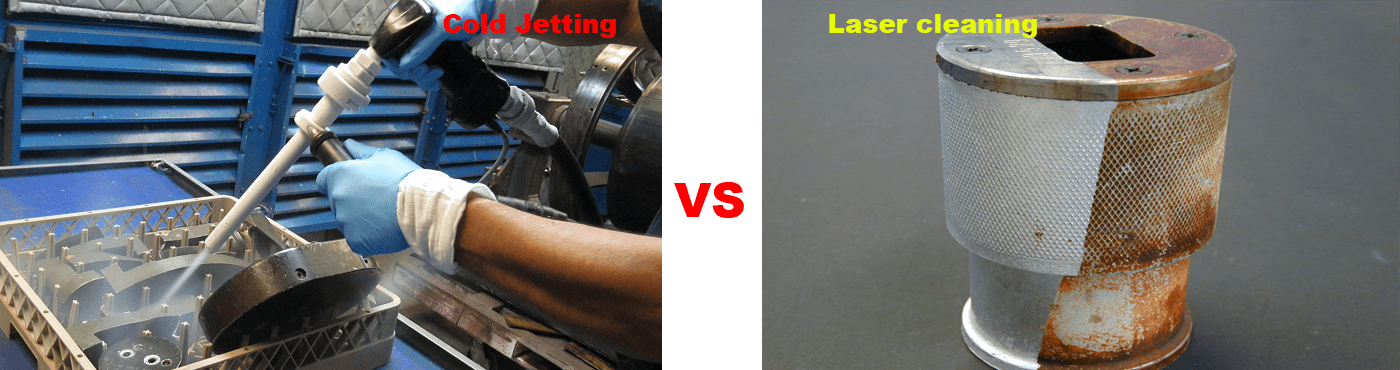

When to Consider Alternative Cleaning Methods

• If your cleaning needs are occasional and low-volume,traditional methods might be more economical.

• For extremely low-budget applications,abrasive blasting may provide short-term savings.

Laser cleaning is most beneficial for businesses seeking efficiency, sustainability, and long-term ROI.

5. How to Choose the Best Laser Cleaner for Your Budget

When selecting a laser cleaning machine, consider the following:

1. Define Your Cleaning Requirements

• What materials are you cleaning?

• How frequently will the machine be used?

• What level of precision do you need?

2. Compare Different Power Levels

• Low-power (50W – 100W): Best for light cleaning tasks.

• Mid-range (200W – 500W): Ideal for industrial maintenance.

• High-power (1000W+):Suitable for heavy-duty applications.

3. Evaluate Additional Features

• Handheld vs. Automated Systems:Portable models offer flexibility, while automated systems enhance efficiency.

• Air-Cooled vs. Water-Cooled Systems:Water-cooled models handle high-power cleaning more effectively.

• Software & Customization:AI-driven control interfaces improve ease of use and precision.

4. Consider Warranty & After-Sales Support

A higher initial investment might be worthwhile if it includes extended warranty, training, and customer support.

6. The Future of Laser Cleaning Costs & Market Trends

With technological advancements, the cost of laser cleaners is expected to decrease while efficiency continues to improve.

Emerging Trends in Laser Cleaning Technology

• More Affordable Compact Models:Increased accessibility for small businesses.

• AI-Driven Cleaning Optimization:Intelligent software for precision cleaning.

• Enhanced Energy Efficiency:Lower power consumption without compromising performance.

As the demand for eco-friendly cleaning solutions grows, businesses investing in laser technology today are setting themselves up for sustainable cost savings in the future.

Final Thoughts: Making an Informed Decision on Laser Cleaner Costs

Laser cleaning is rapidly becoming the preferred method for rust removal, surface preparation, and industrial maintenance. While the initial cost can be significant, the long-term savings, efficiency, and environmental benefits make it a wise investment for businesses requiring regular cleaning.

By carefully evaluating power levels, hidden costs, and long-term ROI, companies can ensure they choose the right laser cleaner at the best price. Whether you’re in manufacturing, automotive restoration, or aerospace, investing in laser cleaning technology could be the key to higher efficiency and lower operational costs.