Handheld Laser Welder Price: Understanding Cost for Maximum Value

A powerful tool in the palm of your hand, a marvel of technology capable of uniting metals with pinpoint precision—the handheld laser welder represents a step into the future of welding. But with all its advantages, one pressing question often comes up: What is the price of a handheld laser welder, and what influences it? From those exploring the world of high-precision welding for the first time to seasoned professionals seeking an upgrade, understanding the factors behind the price of these machines can be a crucial step in making a smart investment. This guide will take you through everything you need to know about handheld laser welder pricing—from the fundamental components and specifications to cost-effectiveness and value-added features provided by CQX technology.

1. What is a Handheld Laser Welder?

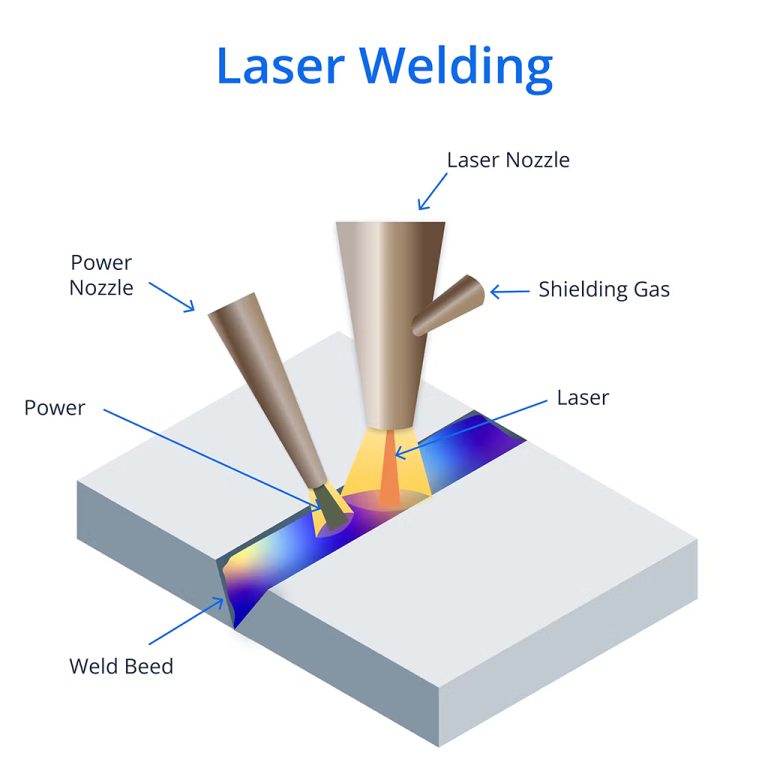

1.1 Overview of Handheld Laser Welding Technology

A handheld laser welder is a portable welding device that employs a focused laser beam to weld materials with unmatched accuracy. Unlike conventional welding machines, handheld models are compact and user-friendly, allowing greater mobility while maintaining high welding precision and speed.

1.2 Key Features of a Handheld Laser Welder

• Portability: Compact size makes it easy to maneuver, perfect for welding tasks on-site or in confined spaces.

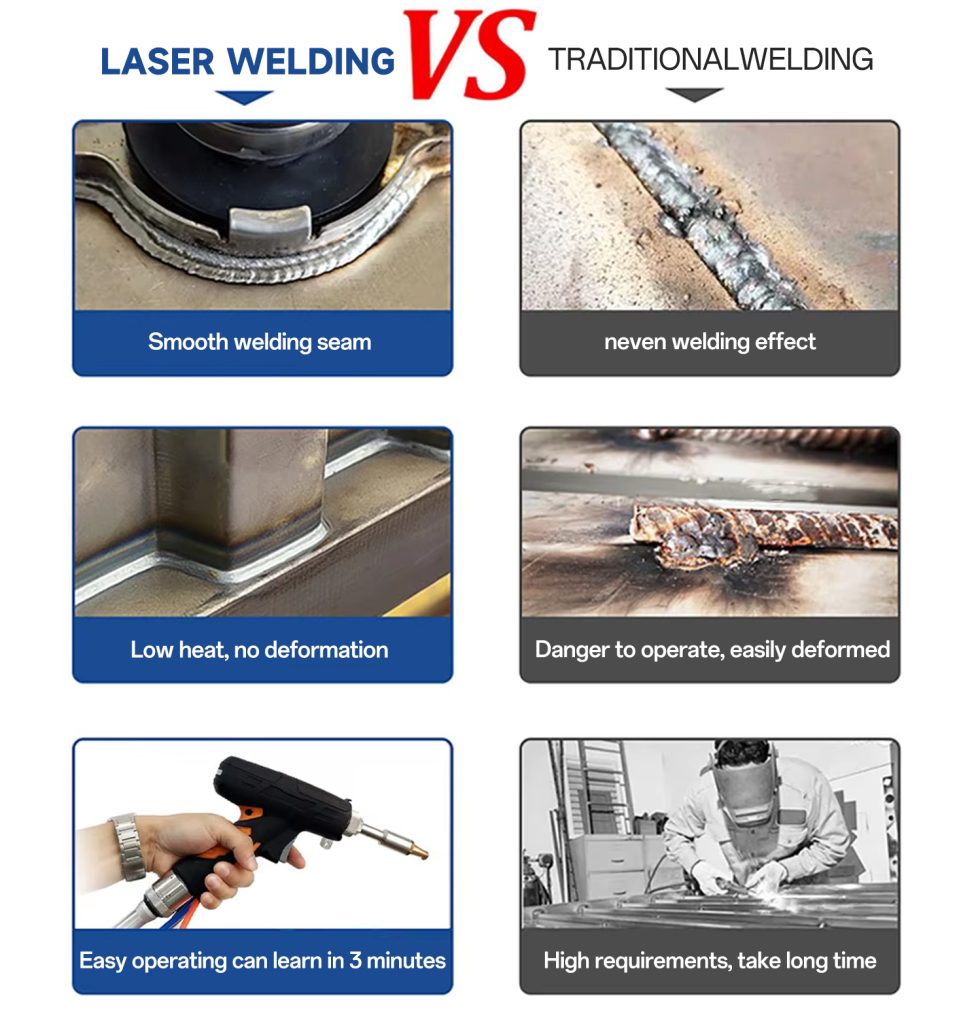

• Precision: Provides high-quality welds with minimal heat-affected zones, reducing the risk of warping or damage to surrounding areas.

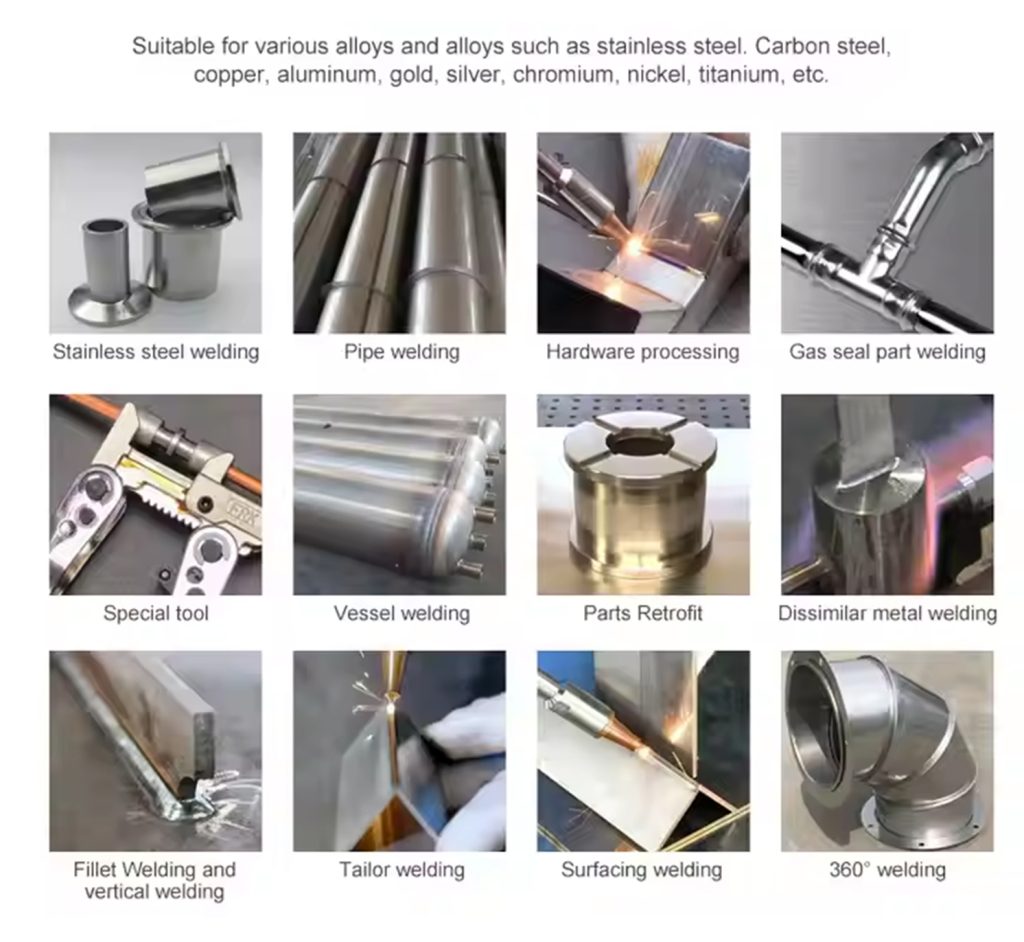

• Versatility: Suitable for various materials including steel, aluminum, copper, and more, making it a valuable tool across multiple industries.

2. Factors Affecting the Price of Handheld Laser Welders

2.1 Laser Power Output

The power output of a laser welder plays a significant role in determining its price. Welders with higher power levels can handle thicker materials and complete welds more quickly, which generally means a higher cost. Laser welders are commonly available in a range of power outputs, from low-power models for small-scale tasks to high-power units for industrial applications.

2.2 Type of Laser Source

The type of laser used—such as fiber laser or CO₂ laser—is another major factor influencing the price. Fiber lasers are more efficient, require less maintenance, and offer better beam quality compared to CO₂ lasers, making them generally more expensive.

2.3 Cooling System

Effective cooling is crucial to maintaining consistent laser performance. Handheld laser welders can be either air-cooled or water-cooled, with water-cooled systems typically being more expensive due to their better efficiency in dissipating heat, particularly for higher-power lasers.

2.4 Automation and Control Features

Advanced features such as automatic focus adjustment, programmable settings, and user-friendly touch screens add to the cost of a handheld laser welder. These features, however, also enhance usability and productivity, making them worth considering.

2.5 Build Quality and Brand Reliability

The overall build quality, materials used, and brand reputation can also influence price. CQX, for instance, focuses on delivering robust and reliable laser welders with a solid warranty, which can add to the upfront cost but ensures long-term reliability and support.

3. Price Ranges of Handheld Laser Welders

3.1 Entry-Level Welders

• Price Range: $3,000 to $8,000

• Target Users: Beginners, hobbyists, or small workshops.

• Capabilities: Basic welding for thinner materials and non-intensive usage.

3.2 Mid-Range Welders

• Price Range: $8,000 to $20,000

• Target Users: Small to medium-sized businesses needing a balance of performance and cost.

• Capabilities: Improved power output and cooling systems for a wider range of materials.

3.3 High-End Welders

• Price Range: $20,000 to $50,000+

• Target Users: Industrial manufacturers, specialized applications requiring high power and precision.

• Capabilities: High power output, advanced control systems, and efficient cooling for intensive usage.

4. How to Assess Value Beyond Price

4.1 Efficiency and Speed

The efficiency of a handheld laser welder directly impacts your productivity. Faster welding speeds mean reduced labor costs and increased throughput, which can offset the initial investment over time. A high-powered CQX handheld laser welder, for example, may have a higher price tag, but the productivity gains make it more cost-effective in the long run.

4.2 Material Versatility

If you need to weld a variety of materials, consider the welder’s versatility.

A machine capable of handling multiple types of metals adds significant value, particularly for industries that require diverse applications.

4.3 Maintenance Requirements

Low maintenance costs contribute to the overall value of the machine.

Fiber lasers typically require less maintenance compared to CO₂ lasers, making them more economical over the lifespan of the welder.

4.4 Energy Efficiency

Laser welding machines consume less energy compared to traditional welding methods.

This reduced energy consumption can lead to significant savings, particularly in large-scale operations where welders are in use for extended periods.

5. Applications of Handheld Laser Welders

5.1 Automotive Industry

In automotive manufacturing, handheld laser welders are used for precision welding of car parts, exhaust systems, and body repairs.

The ability to perform accurate welds without damaging surrounding components makes them invaluable in this industry.

5.2 Aerospace and Aviation

Aerospace applications require welds that are both lightweight and strong.

Handheld laser welders are used for welding thin metals and specialized alloys that must meet stringent safety standards.

5.3 Medical Device Manufacturing

The medical field demands welds with extremely high accuracy to avoid contamination or defects.

Handheld laser welders offer the non-contact welding required for medical devices, ensuring a sterile and precise bond.

5.4 Jewelry and Craftsmanship

For delicate welding tasks such as jewelry repair, handheld laser welders are ideal because they offer fine control and do not generate excessive heat that could damage intricate pieces.

6. How CQX Adds Value with Its Handheld Laser Welders

6.1 Robust Build Quality

CQX handheld laser welders are constructed using high-quality materials designed for durability and reliability, ensuring a long lifespan even with regular use in demanding environments.

6.2 User-Centric Design

With ergonomics in mind, CQX ensures that their handheld laser welders are easy to handle and operate, even for extended periods.

Features like a comfortable grip, intuitive controls, and customizable settings enhance the user experience.

6.3 Comprehensive Training and Support

CQX offers extensive training programs and ongoing support to ensure operators are fully competent in using the equipment, thus maximizing the return on investment for businesses.

7. Future Trends in Handheld Laser Welding

7.1 Automation and AI Integration

The integration of automation and artificial intelligence is on the horizon for handheld laser welding. AI-assisted welding systems will help users achieve optimal welds by automatically adjusting parameters based on real-time feedback.

7.2 Portability with Increased Power

Future advancements aim to increase the power output of handheld models without compromising portability. This evolution will expand the applications of handheld laser welders into more demanding industrial sectors.

7.3 Green Technology

As industries aim for sustainability, the trend towards energy-efficient laser welding solutions is set to continue. Handheld laser welders are inherently more eco-friendly compared to traditional methods, and improvements in energy efficiency will further enhance their appeal.

8. Tips for Buyers: Finding the Right Handheld Laser Welder at the Right Price

8.1 Assess Your Needs

Before making a purchase, evaluate the materials you will be welding, the required power output, and any special features you may need. This will help you choose the right welder that fits your application without overpaying for unnecessary features.

8.2 Compare Different Models

Compare models from different manufacturers, focusing not only on the price but also on features, usability, and after-sales support. Look for user reviews and case studies that provide insights into the real-world performance of the welders.

8.3 Plan for Long-Term Use

Consider the long-term value rather than just the initial cost. Features such as energy efficiency, durability, and maintenance requirements will determine how cost-effective the welder is over its lifespan.

A handheld laser welder can be a game-changer for many businesses, offering the precision, speed, and flexibility needed in today’s competitive market. Understanding what affects the handheld laser welder price and recognizing the value-added features that brands like CQX bring to the table can help you make an informed decision. By balancing upfront costs with the long-term benefits of efficiency, versatility, and low maintenance, you can ensure your investment pays dividends for years to come.