Laser Welder Hand Held: A Game-Changer in Modern Welding

The power of precision, the flexibility of design, and the promise of increased efficiency—these qualities define the handheld laser welder. This innovative tool is transforming the welding industry by making precision laser welding more accessible than ever. Whether you’re welding delicate components or large metal sheets, a handheld laser welder offers a versatile, cost-effective solution that traditional methods struggle to match.

In this detailed guide, you’ll discover everything you need to know about handheld laser welders, from their core features to cost breakdowns and expert tips on selecting the perfect model.

1. What is a Handheld Laser Welder?

A handheld laser welder is a portable device designed to perform laser welding tasks with precision and speed. Unlike automated or benchtop welders, these machines allow users to manually control the laser gun, offering unmatched flexibility for various welding tasks.

Key Benefits of Handheld Laser Welders:

1.ortability: Compact design for ease of use in different work environments.

2.Precision: Achieve pinpoint accuracy, reducing material waste.

3.Ease of Use: User-friendly interfaces and ergonomic designs improve operator comfort.

2. How Does a Handheld Laser Welder Work?

The core mechanism of a handheld laser welder involves directing a concentrated laser beam onto the workpiece. This beam rapidly heats the material, melting the edges and forming a seamless bond. Unlike traditional welding, which relies on fillers and intense heat, laser welding minimizes warping and produces cleaner joints.

3. Why Choose a Handheld Laser Welder Over Traditional Methods?

To understand the full value of a handheld laser welder, consider how it compares to conventional methods such as MIG, TIG, and arc welding.

3.1 Speed and Efficiency

A handheld laser welder can weld up to four times faster than traditional welding methods, thanks to its precise and concentrated heat source.

3.2 Reduced Post-Processing

Laser welds require minimal to no grinding, sanding, or polishing, saving valuable time and resources.

3.3 Versatility

Capable of welding a wide range of materials, including stainless steel, carbon steel, aluminum, and copper, the handheld laser welder is suitable for everything from fine jewelry repairs to large-scale industrial projects.

4. Price Ranges for Handheld Laser Welders

The cost of a handheld laser welder varies depending on power output, brand, and additional features. Below is a detailed breakdown of typical price ranges:

• Entry-Level Models (100W – 500W): $8,000 – $12,000

º Best for small shops and light-duty repairs.

• Mid-Range Models (500W – 1,000W): $12,000 – $20,000

º Suitable for general fabrication and manufacturing.

• High-Power Models (1,000W – 1,500W): $20,000 – $40,000+

º Ideal for heavy-duty industrial applications requiring deep weld penetration.

5. Key Features to Consider When Buying a Handheld Laser Welder

When investing in a handheld laser welder, it’s essential to evaluate the following features:

5.1 Power Output

Higher wattage equals more welding power, but this often comes with increased costs. Choose a machine with the appropriate power level for your typical workpieces.

5.2 Cooling System

Efficient cooling systems (air-cooled vs. water-cooled) can prolong machine life and support continuous operation without overheating.

5.3 Weight and Ergonomics

Since handheld welders require manual operation, prioritize models with lightweight, ergonomic designs to prevent user fatigue during extended use.

5.4 Pulse Mode Settings

Advanced pulse mode settings allow for greater control over the heat input, which is crucial when welding thinner materials.

6. Common Applications of Handheld Laser Welders

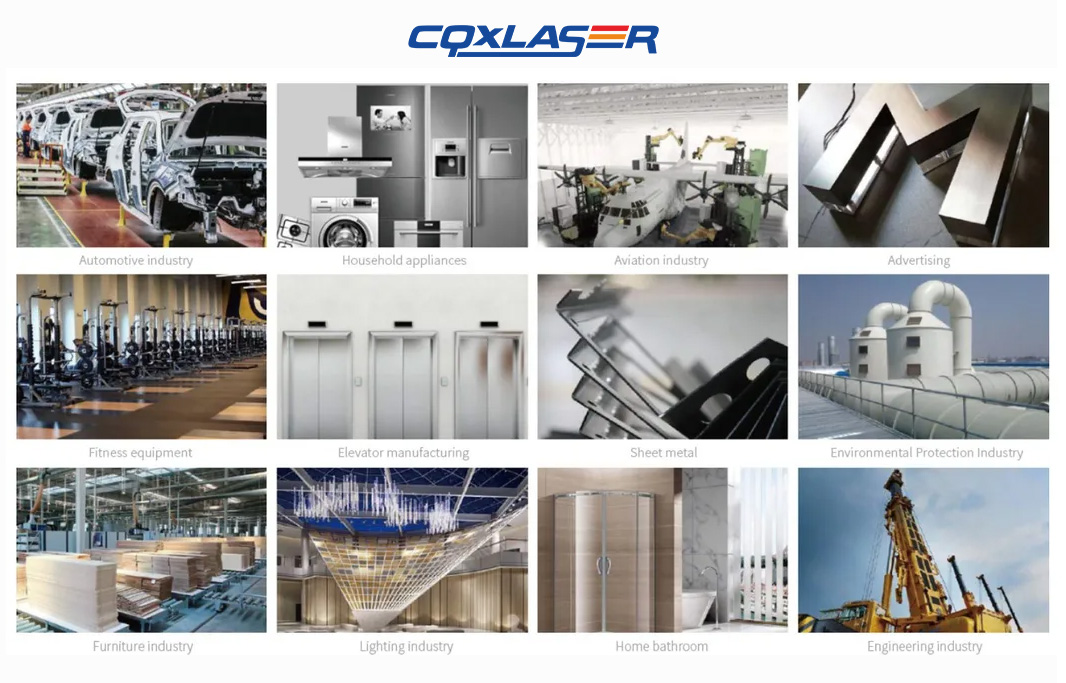

Handheld laser welders are widely used in various industries due to their versatility. Here are some common applications:

• Automotive Industry:Repairing and fabricating car frames, exhaust systems, and custom parts.

• Aerospace:Joining lightweight metal components with minimal warping.

• Jewelry Repair:Precision welding for intricate designs and repairs.

• Home DIY and Custom Projects:Ideal for small-scale repairs and personal projects.

7. Cost vs. Value: Is a Handheld Laser Welder Worth It?

Although the initial investment may seem steep, the long-term benefits of a handheld laser welder make it a cost-effective solution. The combination of reduced labor costs, minimal material waste, and faster turnaround times can result in significant savings over time.

8. Potential Drawbacks to Consider

While handheld laser welders offer numerous advantages, it’s important to consider potential limitations:

• Initial Cost:The upfront cost may be prohibitive for some small businesses.

• Learning Curve:Although user-friendly, operators may require training to optimize performance.

• Maintenance:Regular maintenance is needed to ensure optimal performance and extend the machine’s lifespan.

9. Safety Considerations

Laser welding involves high-intensity beams that can cause injury if not handled properly. Always adhere to the following safety protocols:

1.Wear protective goggles specifically rated for laser use.

2.Ensure adequate ventilation to dissipate any fumes generated during the welding process.

3.Use appropriate gloves and protective clothing to prevent burns.

10. The Future of Handheld Laser Welders

As technology advances, handheld laser welders are expected to become more compact, affordable, and efficient. Innovations such as AI-assisted welding, real-time defect detection, and enhanced portability are already reshaping the industry.

11. Financing and Leasing Options

Many suppliers offer financing and leasing programs to make handheld laser welders more accessible. These options allow businesses to spread the cost over time rather than making a large upfront payment.

12. FAQs About Handheld Laser Welders

Q: What is the lifespan of a handheld laser welder?

A: With proper maintenance, a quality handheld laser welder can last 10 to 15 years.

Q: Can handheld laser welders work on all metals?

A: Most handheld laser welders are compatible with common metals like steel, aluminum, and brass. However, exotic alloys may require specialized settings.

Q: How portable are handheld laser welders?

A: While they are designed to be portable, some models may weigh 20kg or more, so consider the weight and handle design.

By understanding the ins and outs of handheld laser welders, you can make a more informed purchase that aligns with your operational needs and budget. The handheld laser welder isn’t just a tool—it’s an investment in precision, efficiency, and long-term growth.