The Essential Guide to Hand Laser Welders: Precision at Your Fingertips

Innovation, versatility, and efficiency converge in the hand laser welder, a groundbreaking tool designed for precision welding across a variety of materials. Compact yet powerful, this device revolutionizes metalworking, offering unmatched accuracy and ease of use. Whether for industrial applications or intricate craftsmanship, the hand laser welder is an indispensable tool for modern welding needs.

Why a Hand Laser Welder is the Future of Metalworking

The hand laser welder introduces a transformative approach to welding. Its high-energy laser beam offers:

• Precision that minimizes material distortion.

• The ability to work with various metals, including stainless steel, aluminum, and titanium.

• User-friendly handling for on-site or workshop applications.

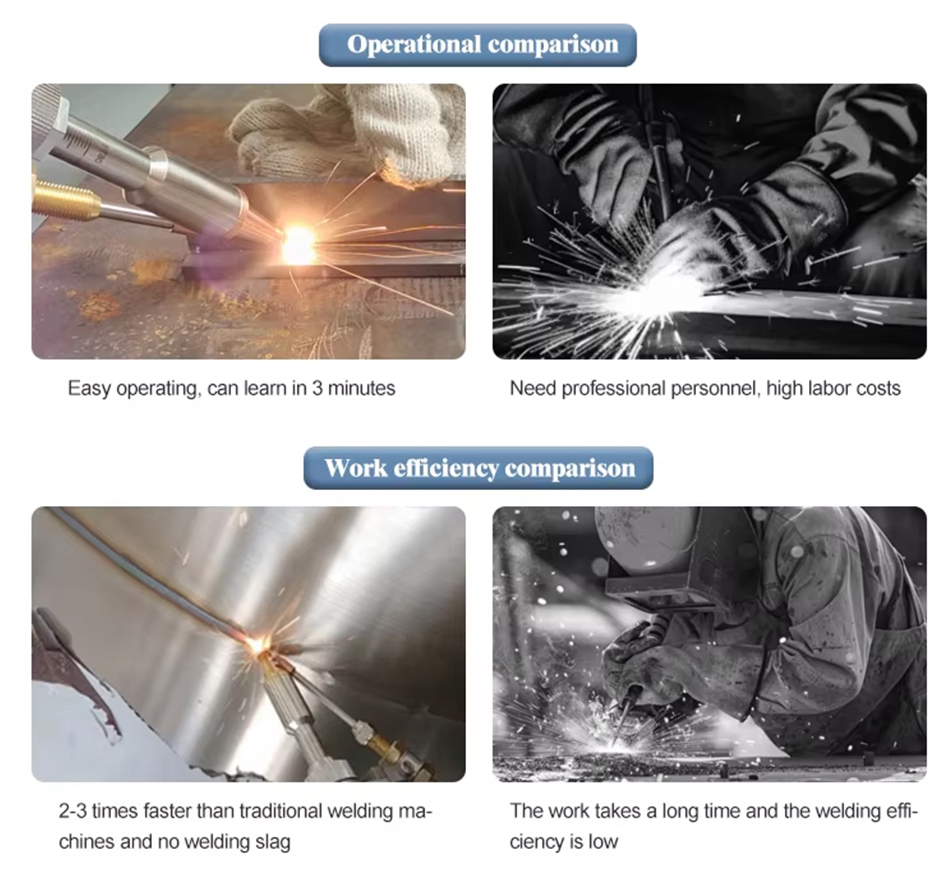

Unlike traditional welding methods, the hand laser welder delivers faster results with superior quality, making it a preferred choice for professionals and hobbyists alike.

Key Features of a Hand Laser Welder

1. Compact and Portable Design

Engineered for flexibility, the hand laser welder is lightweight and easy to maneuver, making it suitable for both confined spaces and large-scale projects.

2. High Precision and Accuracy

Its focused laser beam allows for intricate welding tasks, reducing errors and ensuring consistent results, even with delicate materials.

3. Versatility Across Materials

From thin sheets to thick metals, the device handles a wide range of materials effortlessly, eliminating the need for multiple welding tools.

4. Minimal Post-Weld Processing

The clean and smooth welds produced by the laser reduce the need for grinding or polishing, saving time and effort.

5. Energy Efficiency

Laser welding consumes less energy compared to traditional methods, making it an environmentally friendly choice.

Applications of Hand Laser Welders

1. Automotive Industry

Hand laser welders are invaluable for repairing and manufacturing automotive components. Their precision ensures safety and durability in critical applications like engine parts and exhaust systems.

2. Aerospace Sector

In aerospace engineering, lightweight and high-strength materials are essential. Laser welding provides the necessary accuracy and consistency for aircraft components.

3. Jewelry and Artistic Craftsmanship

Artisans benefit from the precision of hand laser welders, enabling the creation of intricate designs and repairs on delicate pieces.

4. Industrial Manufacturing

From assembling machinery to fabricating metal structures, laser welding streamlines production processes while ensuring top-notch quality.

5. Custom Fabrication and Prototyping

For small businesses and DIY enthusiasts, the hand laser welder provides professional-grade results without requiring industrial-scale equipment.

How Hand Laser Welding Works

Step 1: Preparation

The surface is cleaned to remove dirt, rust, or coatings, ensuring maximum laser absorption.

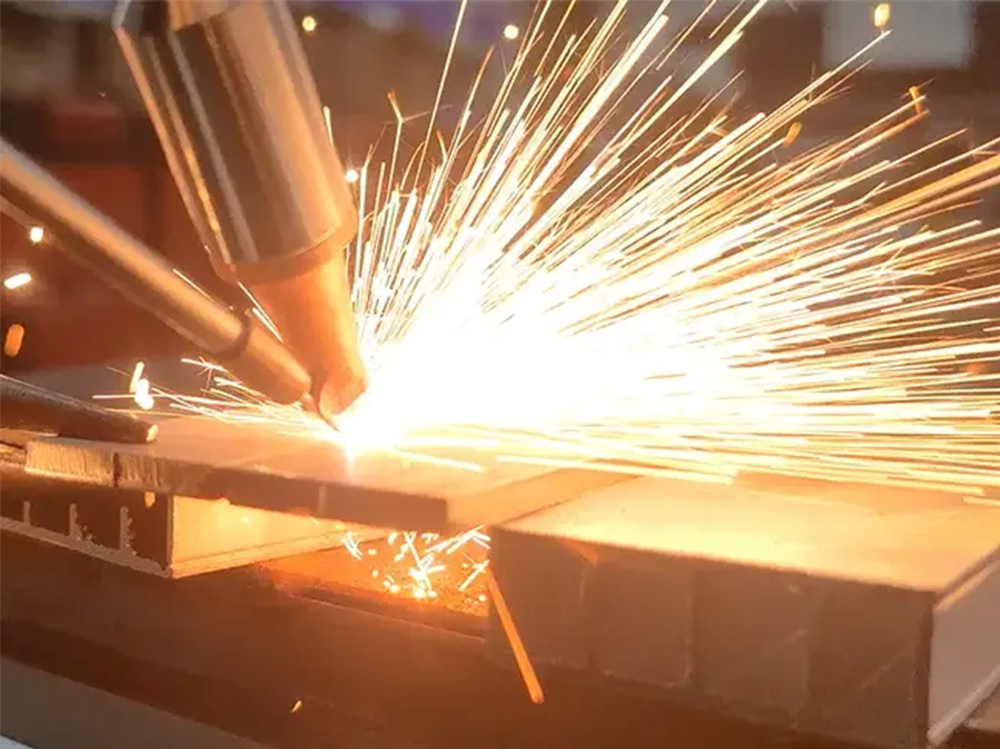

Step 2: Laser Beam Application

A high-energy laser beam melts the materials at the joint, forming a molten pool.

Step 3: Fusion and Solidification

As the laser moves, the molten metal solidifies, creating a strong and seamless weld.

The process is quick and efficient, with most welds completed in seconds depending on the material and thickness.

Advantages Over Traditional Welding

Speed and Efficiency

Laser welding drastically reduces welding times while maintaining high-quality results.

Reduced Heat Affected Zone (HAZ)

The focused energy minimizes heat spread, reducing the risk of warping or distortion.

Enhanced Aesthetic Quality

The clean, precise welds produced by laser technology often eliminate the need for post-processing.

Cost-Effectiveness

While the initial investment may be higher, the long-term savings in time, materials, and energy outweigh traditional methods.

Choosing the Right Hand Laser Welder

1. Power Output

A higher wattage offers deeper penetration and faster welding speeds, ideal for industrial use.

2. Cooling System

Effective cooling mechanisms prevent overheating and prolong the machine’s lifespan.

3. Ease of Use

User-friendly controls and ergonomic designs enhance productivity and reduce operator fatigue.

4. Safety Features

Look for models with built-in safeguards such as automatic shutoff and protective casings.

Safety Precautions

Working with a hand laser welder requires adherence to safety guidelines:

• Wear protective eyewear specifically rated for laser exposure.

• Operate in a well-ventilated area to avoid inhaling fumes.

• Ensure the workspace is free from flammable materials.

Economic and Environmental Benefits

Cost Efficiency

The ability to perform precision welding quickly reduces labor and operational costs.

Sustainability

Laser technology’s low energy consumption and minimal material waste make it an eco-friendly solution for modern industries.

The Future of Hand Laser Welders

The evolution of hand laser welders is driven by innovation and user demand. Anticipated advancements include:

1. AI Integration: Real-time monitoring and automatic adjustments for optimal welding conditions.

2. Enhanced Portability: Lighter and more compact designs for increased flexibility.

3. Improved Energy Efficiency: Advanced laser diodes will further reduce power consumption.

Final Thoughts

A hand laser welder is more than just a tool—it’s a game-changer. By delivering precision, efficiency, and versatility, it empowers professionals and enthusiasts to achieve results that were once considered unattainable. Investing in this technology is an investment in the future of welding, offering opportunities to innovate and excel in any project.

Take the leap into modern welding solutions with a hand laser welder, and experience the difference precision can make.