Hand Held Laser Welder: Unlocking Precision in Your Hands

Imagine holding the future of welding in your hands—a compact yet powerful tool that gives you the freedom to weld with precision, finesse, and control. The hand held laser welder is not just an innovation; it’s a leap into a world where speed, versatility, and efficiency come together in perfect harmony. Whether you’re repairing delicate jewelry or assembling complex industrial parts, this technology allows you to work with confidence and ease, making traditional welding methods seem archaic. This guide will take you through the incredible potential of hand held laser welders, how they work, and why they’re rapidly becoming the go-to tool for craftsmen and manufacturers worldwide.

1.What is a Hand Held Laser Welder?

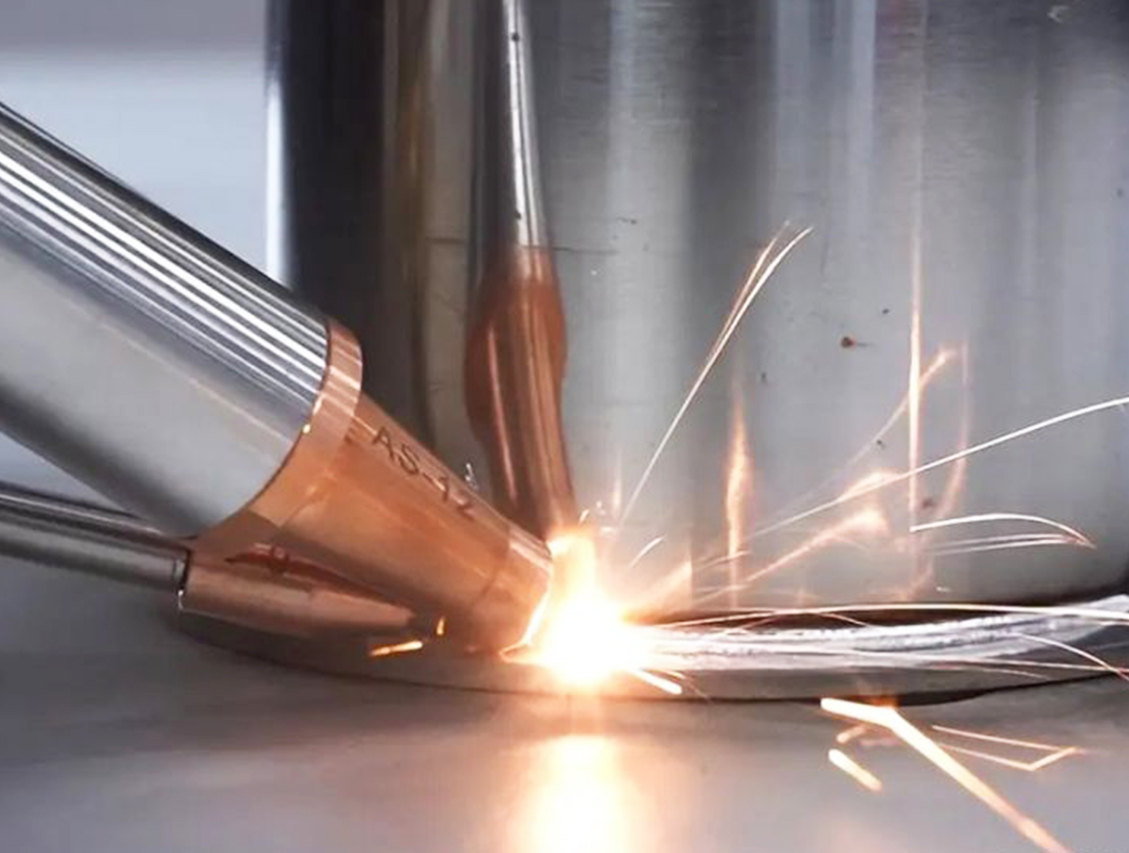

1.1 Understanding Hand Held Laser Welding Technology

A hand held laser welder is a portable welding device that uses a focused laser beam to join materials with extreme precision. Unlike conventional welders that are often cumbersome, the handheld laser welder is designed to be user-friendly and easy to operate while maintaining high standards of accuracy and performance.

1.2 Key Features of Hand Held Laser Welders

• Portability: Lightweight and ergonomic, allowing operators to maneuver with ease.

• Precision: The laser beam ensures clean and precise welds, reducing the need for extensive finishing.

• Versatility: Effective on a wide range of materials, including metals like stainless steel, aluminum, and even reflective surfaces.

2.How Does a Hand Held Laser Welder Work?

2.1 The Science Behind Laser Welding

The technology behind a hand held laser welder revolves around the use of a high-energy laser beam that melts the surface of the material to create a weld joint. The focused energy produces minimal heat dispersion, reducing the risks of warping or damaging surrounding areas. The concentrated beam provides a deep weld with minimal material waste, making it an ideal choice for precision work.

2.2 Components of a Hand Held Laser Welder

• Laser Source: Typically a fiber laser, which is highly efficient and low-maintenance.

• Cooling System: Ensures the laser operates at optimal temperatures, preventing overheating.

• Control Interface: User-friendly controls to adjust power, focus, and welding parameters.

3. The Advantages of Hand Held Laser Welders

3.1 Unparalleled Precision and Control

Hand held laser welders provide the ability to create fine, detailed welds that are nearly impossible with traditional welding techniques.

The focused laser beam ensures a high level of precision, making it ideal for intricate work.

3.2 Versatility Across Industries

From aerospace to automotive, jewelry to electronics, the versatility of hand held laser welders makes them suitable for a diverse range of applications.

Their ability to handle various materials with different thicknesses provides flexibility for multiple industries.

3.3 Faster and More Efficient Welding

Compared to traditional welding methods, laser welding is significantly faster. The high energy density of the laser allows for quick welds, improving productivity and reducing overall project timelines.

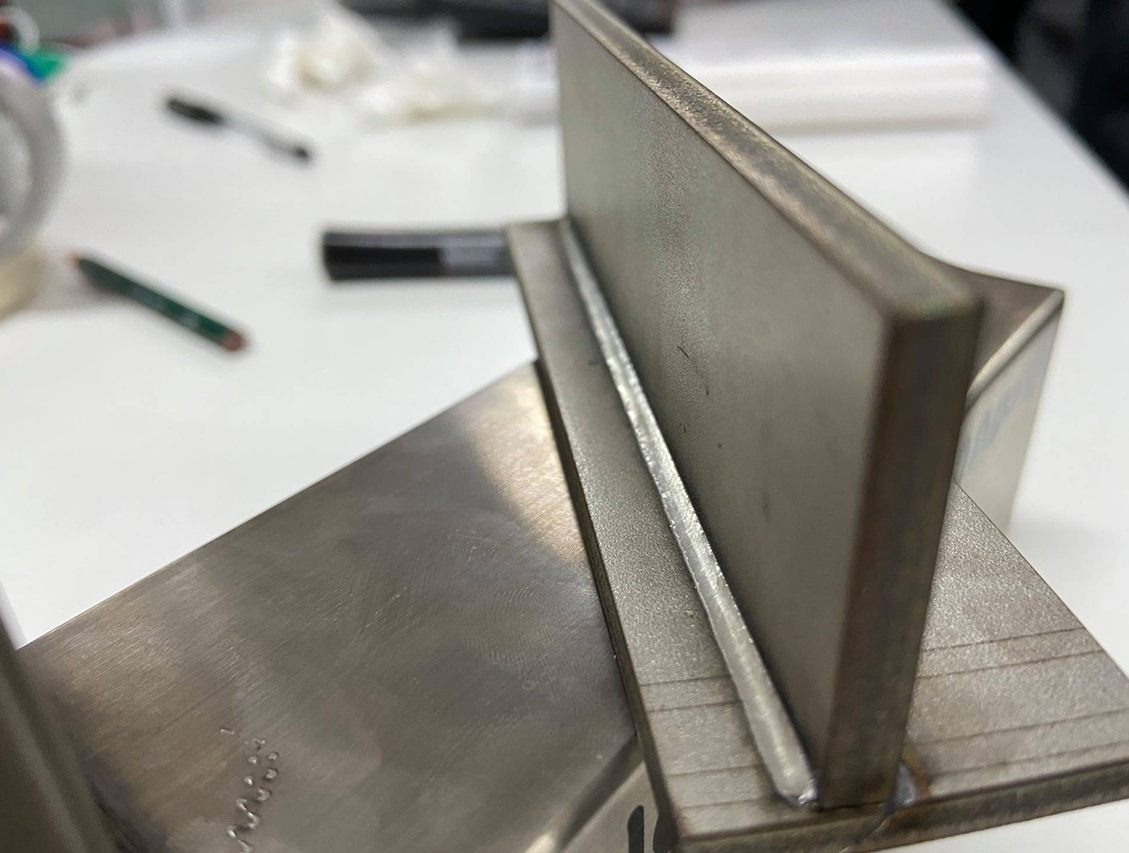

3.4 Minimal Post-Weld Finishing

Laser welders produce clean and precise welds, meaning there is little to no need for grinding or polishing afterward. This saves time and reduces the labor associated with finishing tasks.

4. Applications of Hand Held Laser Welders

4.1 Jewelry and Fine Metalwork

The precision offered by hand held laser welders makes them perfect for jewelry repair and fine metalwork.

They can handle delicate pieces without damaging the surrounding areas, maintaining the integrity of valuable items.

4.2 Automotive Industry

In the automotive sector, hand held laser welders are used for assembling components that require precise and durable welds.

They are ideal for welding thin sheets, batteries, and intricate engine parts.

4.3 Construction and Fabrication

Hand held laser welders are increasingly being used in construction for onsite welding.

Their portability allows workers to easily move around the worksite and perform welds in tight or awkward spaces.

4.4 Electronics and Microfabrication

The electronics industry benefits from laser welders’ ability to create micro-welds on small components without generating excessive heat, which could potentially damage sensitive electronic parts.

5. Comparing Hand Held Laser Welders to Traditional Welding Methods

5.1 Heat Affected Zone (HAZ)

The heat affected zone is much smaller with laser welding compared to traditional welding methods, reducing the risk of distortion or material weakening. This is particularly important for applications involving delicate or heat-sensitive materials.

5.2 Ease of Use

Hand held laser welders are designed with ergonomics and user experience in mind. Unlike traditional welding setups that often require extensive training, laser welders are intuitive, allowing operators to quickly learn and achieve high-quality results.

5.3 Flexibility and Mobility

The compact nature of hand held laser welders makes them far more flexible than conventional welding systems. Operators can move freely and perform welds in locations that would otherwise be challenging with bulky equipment.

6. Factors to Consider When Choosing a Hand Held Laser Welder

6.1 Power Requirements

Laser power determines the type of materials that can be welded and the thickness that can be handled. Depending on your application, selecting the appropriate power output is crucial for optimal performance.

6.2 Cooling System Efficiency

The efficiency of the cooling system affects the longevity and performance of the laser. Water-cooled systems are generally more effective for continuous use compared to air-cooled alternatives.

6.3 Safety Features

Hand held laser welders should be equipped with adequate safety features, such as protective eyewear, automatic shutdown, and proper insulation, to ensure user safety during operation.

6.4 Brand Reliability

Opting for a reliable brand like CQX can provide assurance in terms of machine quality, technical support, and the availability of replacement parts. Quality is paramount when investing in a hand held laser welder.

7. The Future of Hand Held Laser Welding

7.1 Technological Advancements

As technology advances, hand held laser welders are becoming more compact, more powerful, and more affordable. Innovations in laser technology are driving improvements in beam quality, efficiency, and safety.

7.2 Increased Adoption Across Industries

The adoption of hand held laser welders is expected to increase as industries recognize their potential for enhancing production efficiency, reducing costs, and improving product quality.

7.3 Environmental Impact

Laser welding is an environmentally friendly process that consumes less energy and produces minimal waste. As sustainability becomes a priority, hand held laser welders offer an attractive solution for manufacturers looking to reduce their carbon footprint.

Hand held laser welders represent a significant step forward in welding technology. They combine portability, precision, and power in a way that traditional welding tools simply cannot match. From intricate jewelry repairs to demanding automotive and aerospace applications, these versatile tools are reshaping the way we think about welding. As CQX continues to innovate, the future looks promising for those who choose to invest in the cutting-edge potential of hand held laser welding.