Fiber Laser Cleaning Machine: Revolutionizing Precision Surface Cleaning

In a world where precision and efficiency define industrial progress, the fiber laser cleaning machine emerges as a technological marvel. Imagine eliminating rust, grease, and paint effortlessly—without damaging the surface underneath. This isn’t just a cleaning method; it’s a transformative leap into the future of surface treatment.

Understanding Fiber Laser Cleaning Machines

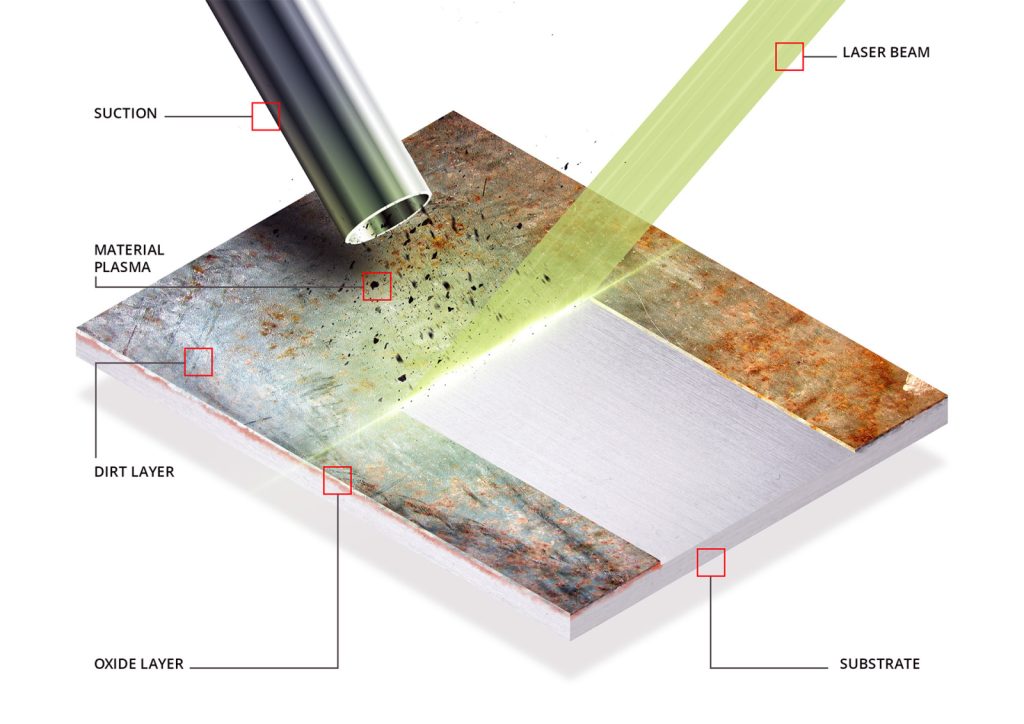

Fiber laser cleaning machines use concentrated laser beams to remove surface contaminants such as rust, paint, and oxidation. By targeting only the undesired material, this method leaves the base material intact, making it an ideal solution for industries that demand high precision.

How Fiber Laser Cleaning Works

1.Energy Pulses: A concentrated light beam generates pulses that interact with the rust.

2.Heat Transfer: The laser’s energy is absorbed by rust, causing rapid expansion and vaporization.

3.Non-Contact Cleaning: Since lasers don’t physically touch the surface, there’s no risk of scratches or wear.

This non-contact method reduces wear and tear, making it both efficient and safe for sensitive materials.

Benefits of a Fiber Laser Cleaning Machine

1. Environmentally Friendly

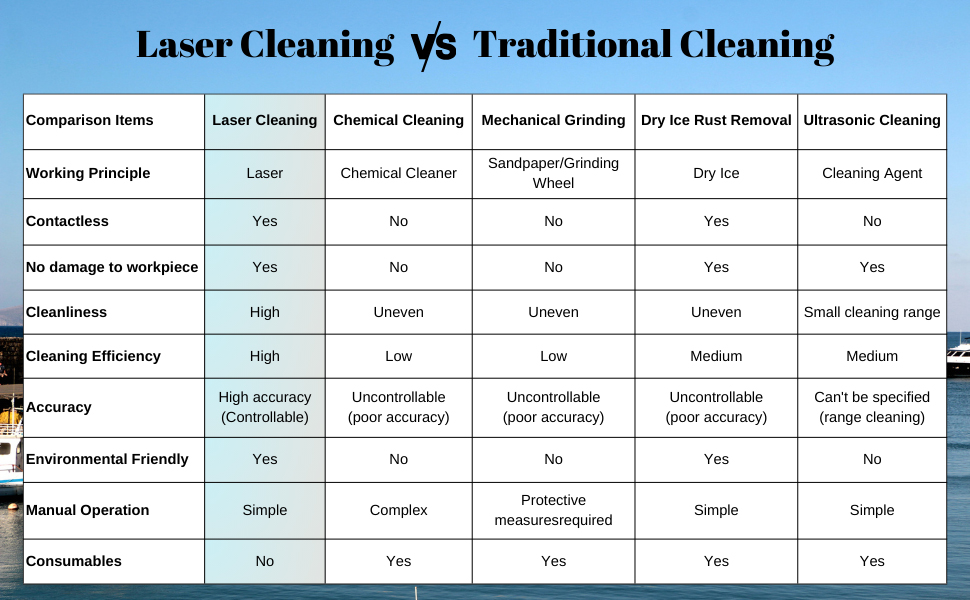

Unlike chemical cleaning, fiber laser cleaning machines use no harmful solvents or abrasives. This reduces chemical waste and improves workplace safety.

2.Cost-Effective Maintenance

The minimal need for consumables, such as chemical agents or pads, translates to lower operational costs over time.

3. Precision and Versatility

Fiber lasers can be adjusted for different cleaning intensities, making them suitable for tasks ranging from light surface cleaning to deep rust removal.

4. No Surface Damage

Traditional methods often leave scratches or dents. Fiber laser cleaning is non-invasive, ensuring the structural integrity of components.

5. Reduced Downtime

Fiber laser systems are fast and require minimal setup, making them an ideal choice for industries that cannot afford prolonged downtime.

Key Applications of Fiber Laser Cleaning Machines

1. Automotive and Aerospace Industry

Removing rust and paint from vehicle frames, engine parts, and aircraft components has never been more efficient. Fiber lasers clean without introducing heat stress or compromising material strength.

2. Manufacturing and Production Lines

Industrial machinery must remain rust-free to ensure optimal performance. Fiber laser cleaning machines can remove contaminants from molds, gears, and precision parts.

3. Shipbuilding and Marine Industry

Ships and offshore structures face constant exposure to saltwater, leading to rapid corrosion. Fiber laser cleaning offers a safe and effective way to remove rust and prepare surfaces for repainting.

4. Electronics Industry

Fiber laser cleaning is delicate enough to clean metal contact points without damaging sensitive electronic components.

5. Restoration of Historical Artifacts

Preservation specialists use fiber lasers to clean sculptures, monuments, and relics without harming the original material.

Types of Fiber Laser Cleaning Machines

There are several variations of fiber laser cleaning machines, each designed for specific tasks:

How Fiber Laser Cleaning Works

1.Portable Handheld Units: Ideal for fieldwork or on-site maintenance.

2.Stationary Systems: Used in factories for continuous production lines.

3.Automated Cleaning Systems: Integrated with robotics for precision cleaning at scale.

Factors to Consider When Choosing a Fiber Laser Cleaning Machine

1. Power Output

Higher power settings are suitable for thick rust removal, while lower power is best for delicate cleaning tasks.

2. Cooling System

Efficient cooling prevents the laser from overheating during extended use.

3. Portability

For off-site cleaning tasks, portable units with lightweight designs are more practical.

4. Adjustability

Machines with customizable pulse frequencies and power settings offer greater control for various cleaning applications.

5. Safety Features

Ensure the system includes protective measures such as shielding and automatic shut-offs to prevent accidental exposure.

Maintenance Tips for Fiber Laser Cleaning Machines

To maximize the lifespan of your fiber laser cleaning machine:

How Fiber Laser Cleaning Works

1.Clean the Optics: Keep the lens free from dust and debris.

2.Check the Cooling System: Ensure the cooling unit functions correctly to avoid overheating.

3.Inspect Fiber Cables: Regularly check for any signs of wear or damage.

4.Update Firmware: Install software updates to maintain optimal system performance.

Innovations in Fiber Laser Cleaning Technology

Recent advancements have made fiber laser cleaning machines even more efficient and accessible. Portable models are now lighter and more energy-efficient, making them practical for small workshops and large-scale industrial use. Future developments may focus on AI-driven systems capable of auto-detecting surface conditions and adjusting cleaning settings accordingly.

Why Fiber Laser Cleaning Machines Are the Future of Surface Treatment

Fiber laser cleaning machines are more than just tools—they’re solutions to long-standing industrial challenges. They eliminate the need for abrasive materials, reduce environmental impact, and streamline cleaning processes across industries. Whether you’re restoring valuable equipment, preparing surfaces for welding, or maintaining production lines, investing in a fiber laser cleaning machine means choosing innovation and precision.

Laser cleaning is reshaping industries and delivering unmatched results. As technology continues to evolve, fiber laser cleaning machines will remain at the forefront of safe, efficient, and sustainable surface treatment solutions.