Laser welding machines have indeed gained significant popularity due to their many advantages over traditional welding methods. Here’s a detailed overview based on the points you mentioned:

Advantages of Laser Welding Machines

- Speed and Precision: Laser welding machines can weld quickly with deep penetration and narrow welds. This results in minimal deformation and reduces the amount of post-processing required.

- Safety: Being non-contact, laser welding reduces the risk of physical harm during operation. However, strict safety measures must be in place to avoid exposure to the laser beam.

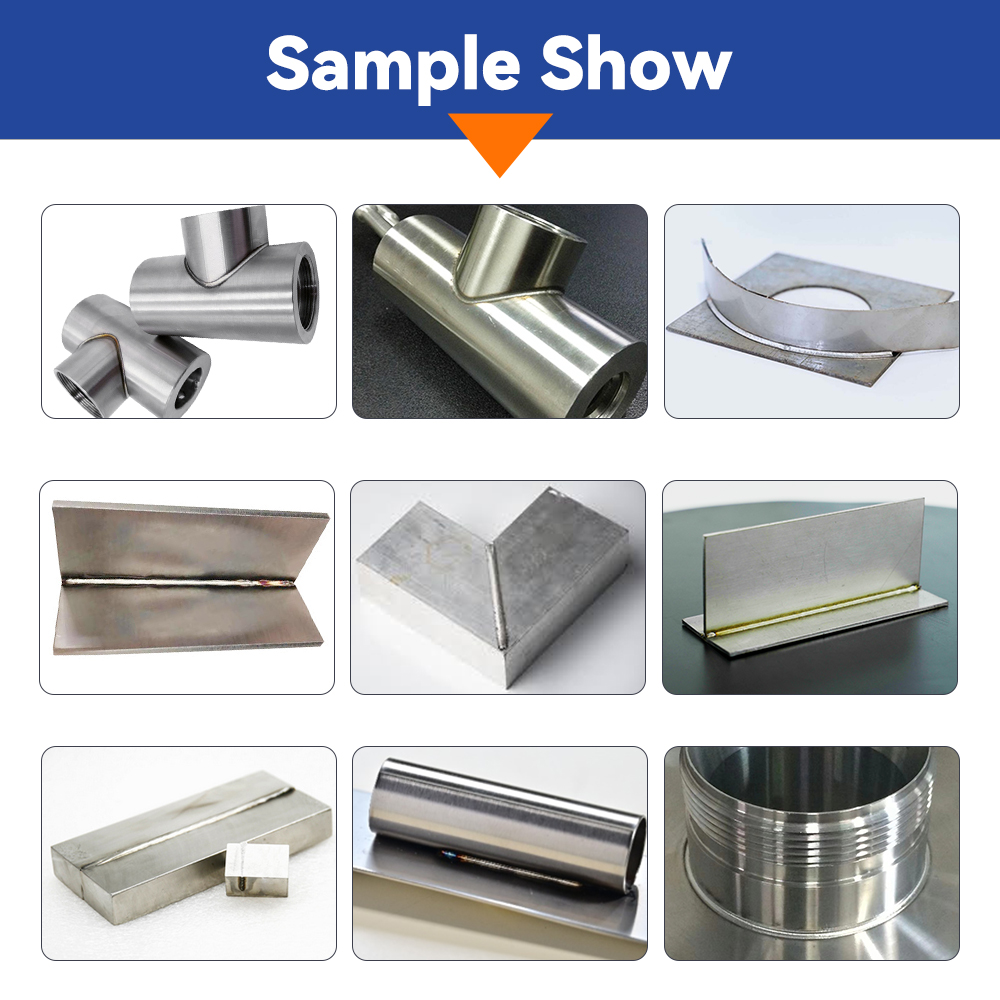

- Versatility: These machines can weld a wide range of materials, including metals that are difficult to weld with traditional methods. They can also join dissimilar metals and non-metallic materials like plexiglass and ceramics.

- Flexibility: Laser welding is highly adaptable, capable of welding complex shapes and hard-to-reach areas, which enhances its application range.

- Precision: The ability to adjust the spot size allows for very fine, precise welding, making it suitable for small and intricate components.

- Automation and Cost Efficiency: Laser welding machines can be integrated into automated production lines, increasing efficiency and reducing labor costs over time.

- Environmental Adaptability: They are not limited by welding conditions and can operate effectively in various weather, temperature, and environmental conditions.

Disadvantages of Laser Welding Machines

- Focusing Range: The laser beam has a limited focusing range. The workpiece must be precisely positioned within this range to avoid defects in the weld.

- Gas Emission: During high-speed welding, vaporized material can create gas that needs to be adequately managed to prevent issues like porosity in the weld.

- Cost: The initial investment in laser welding machines is high, and the operational cost can be influenced by the efficiency of the laser’s photoelectric conversion.

Overall, while laser welding machines present some challenges, their benefits often outweigh the drawbacks, especially in applications requiring high precision, versatility, and automation.