Cleaning Rust with Laser: The Ultimate Guide to Advanced Rust Removal

Rust—stubborn, pervasive, and damaging—plagues industrial machinery, vehicles, and valuable tools. Yet, an innovative revolution in cleaning methods has arrived: cleaning rust with laser technology. Imagine a method so precise that it melts rust away without harming the underlying material, a method that is eco-friendly, non-abrasive, and highly efficient. This is not a distant future but today’s reality.

1. The Science Behind Laser Cleaning Technology

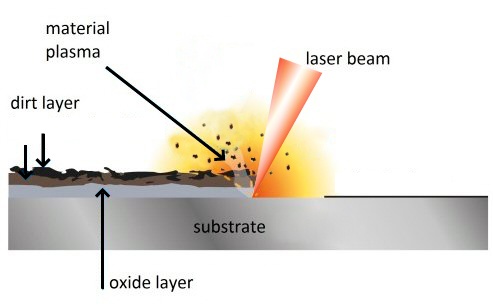

Laser cleaning utilizes focused beams of high-energy light to vaporize contaminants like rust, paint, or dirt. Unlike traditional methods that rely on friction or harsh chemicals, lasers precisely target oxidation layers, converting rust into vapor while leaving the base material intact. This process is known as laser ablation, and it’s revolutionizing industries ranging from automotive restoration to aerospace maintenance.

How Does Laser Rust Removal Work?

• Energy Pulses: A concentrated light beam generates pulses that interact with the rust.

• Heat Transfer: The laser’s energy is absorbed by rust, causing rapid expansion and vaporization.

• Non-Contact Cleaning: Since lasers don’t physically touch the surface, there’s no risk of scratches or wear.

2.Benefits of Cleaning Rust with Laser

When compared to sandblasting, chemical treatments, or grinding, laser cleaning stands out for several reasons:

1.Eco-Friendly and Chemical-Free

Laser cleaning doesn’t require harsh chemicals that could seep into the environment or harm workers. It relies solely on light energy.

2.Non-Abrasive and Safe for Surfaces

Unlike abrasive techniques, lasers preserve the underlying metal. This makes it an excellent option for delicate or expensive components.

3.Precision Cleaning

Lasers can be adjusted for varying depths, making them ideal for intricate surfaces or hard-to-reach areas.

4.Reduced Waste and Maintenance

With minimal residue left behind, post-cleaning tasks are reduced, and there’s no need for disposable cleaning agents.

3.Laser Cleaning in Different Industries

1.Automotive Restoration

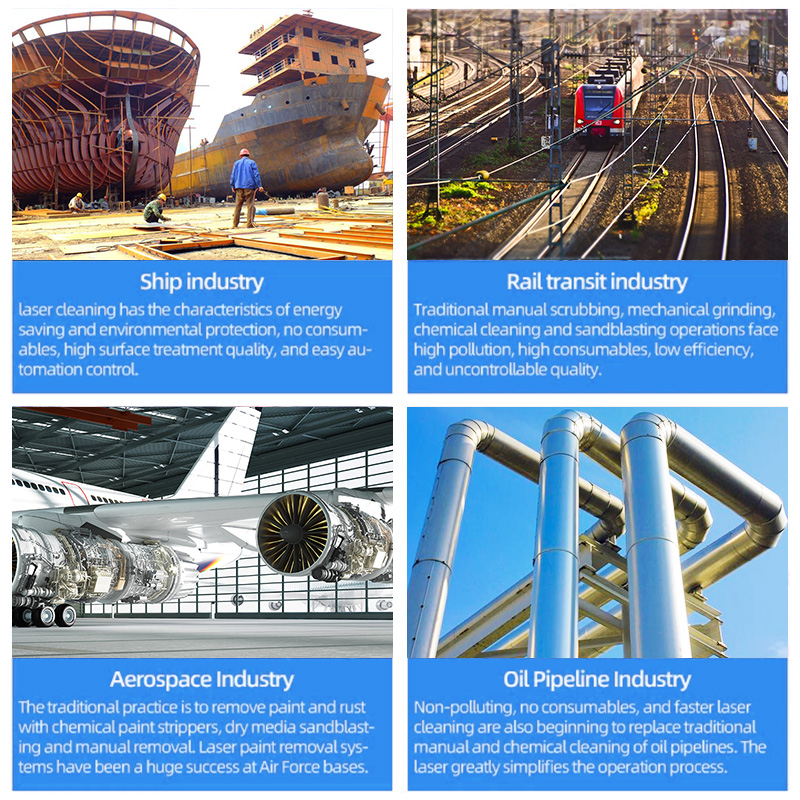

Rust removal with laser cleaning restores car frames, engine parts, and custom restorations with unmatched precision. Vintage car restorers often prefer this method due to its non-invasive nature.

2.Aerospace Maintenance

Aircraft components require precision cleaning to avoid weakening structures. Laser technology excels in safely removing oxidation without altering metal integrity.

3.Manufacturing and Tool Maintenance

Factories rely on laser cleaning to maintain machinery, ensuring that gears, molds, and engines remain rust-free without shutting down production for long periods.

4.Cultural Heritage Preservation

Monuments, sculptures, and historical artifacts benefit from laser cleaning, which gently removes surface contaminants without damaging the original structure.

4.How Laser Systems Are Adapted for Rust Removal

There are several types of lasers used for cleaning rust:

• Pulsed Fiber Lasers: Ideal for precision work and delicate surfaces.

• Continuous Wave Lasers: Suitable for larger, more uniform surfaces.

• Portable Handheld Lasers: Flexible solutions for fieldwork and mobile cleaning tasks.

Key Features of Laser Cleaning Systems

• Adjustable Power Settings: Allows customization for varying levels of rust removal.

• Automatic Safety Features: Integrated shields and controls prevent harmful exposure.

• Low Maintenance Costs: These systems require minimal upkeep compared to traditional cleaning machines.

5.Potential Challenges and Limitations

Although cleaning rust with laser has numerous advantages, it’s essential to acknowledge certain limitations:

• Initial Cost: Laser cleaning systems have a higher upfront cost compared to conventional tools.

• Learning Curve: Operators may require specialized training to maximize efficiency and safety.

• Power Requirements: Laser systems may require high power levels, especially for large-scale industrial cleaning.

6.Future Trends in Laser Cleaning Technology

With ongoing innovations, laser cleaning systems are becoming more affordable, compact, and user-friendly. Researchers are developing AI-assisted systems that can detect rust intensity and automatically adjust laser settings for optimal cleaning performance.

Additionally, advancements in green laser technology—which enhances absorption rates for non-metal surfaces—are expanding the potential applications for laser cleaning beyond metal restoration.

7.How to Choose the Right Laser Cleaning System

When selecting a laser system for rust removal, consider the following:

• Surface Type: Determine whether the surface is delicate, hard, or layered.

• Rust Intensity: Measure the thickness and coverage of the rust.

• Portability Needs: Choose between stationary systems for factory use and portable handheld units for mobile tasks.

Maintenance Tips for Laser Cleaning Equipment

To ensure longevity and performance:

1.Regularly inspect the lens for dust and residue.

2.Keep the cooling system clean to prevent overheating.

3.Follow manufacturer guidelines for software updates and calibrations.

8.Final Thoughts: Transform Rust Removal with Laser Technology

Laser rust cleaning represents a paradigm shift in surface preparation and restoration. It eliminates the need for corrosive chemicals and abrasive tools while delivering superior results. Whether you’re restoring a classic car, maintaining aerospace equipment, or preserving historical artifacts, cleaning rust with laser is the safest, most efficient, and environmentally friendly solution.

For industries and hobbyists alike, embracing this cutting-edge technology is more than an upgrade—it’s the future of rust removal.