2000W Laser Cleaner: The Ultimate Solution for Industrial-Scale Cleaning

Introduction: Why 2000W Laser Cleaners Are Changing Industrial Maintenance

Imagine effortless rust removal, precise paint stripping, and efficient surface restoration, all without chemicals, abrasives, or excessive labor. Traditional methods like sandblasting, chemical treatments, and manual grinding are messy, time-consuming, and often damaging.

Enter the 2000W laser cleaner, a high-power, precision-based industrial cleaning tool that is transforming maintenance across automotive, aerospace, manufacturing, and heavy equipment industries. With its ability to vaporize contaminants without damaging surfaces, it’s becoming the preferred choice for large-scale and high-demand cleaning applications.

What makes the 2000-watt laser cleaner superior? How does it compare to other cleaning technologies? Let’s explore its technology, applications, pricing, and long-term benefits.

1. Understanding the 2000W Laser Cleaner

A 2000W laser cleaner is a high-intensity fiber laser system designed to remove rust, paint, grease, coatings, and oxidation from a variety of surfaces. Unlike traditional methods, this laser technology is:

• Non-contact– No mechanical friction or surface damage.

• Eco-friendly– No chemical waste or hazardous byproducts.

• Cost-efficient– Eliminates recurring costs of consumables and reduces labor.

How Does It Work?

1. The laser beam is directed at the contaminated area.

2. The rust or coating absorbs the laser energy, causing instant thermal expansion and vaporization.

3. The contaminants are safely removed without harming the base material.

4. No additional cleaning steps are needed—no mess, no residue.

With 2000W of power, this laser can clean large surface areas quickly, making it perfect for industrial-scale applications.

2. Why Choose a 2000W Laser Cleaner Over Other Methods?

Industrial cleaning has traditionally relied on abrasives, chemicals, and manual processes, but these come with significant drawbacks:

| Method | Pros | Cons |

|---|---|---|

| Sandblasting | Effective for large-scale rust removal | Creates dust, wears down surfaces, requires clean-up |

| Chemical Cleaning | Can dissolve certain coatings | Hazardous, slow, requires disposal of toxic waste |

| Grinding & Scraping | Low cost, simple | Labor-intensive, damages surfaces |

| 2000W Laser Cleaning | Fast, precise, no waste, eco-friendly | Higher initial investment, requires trained operation |

A 2000W laser cleaner eliminates the inefficiencies of these outdated methods, offering:

• 5–10x faster cleaning speedsthan lower-powered alternatives.

• No consumables(sand, chemicals, or grinding pads).

• No damage to delicate surfaces.

• Reduced maintenance costsdue to its long lifespan.

For industries seeking reliability, precision, and environmental compliance, this laser cleaning technology is the best investment.

3. Key Applications of a 2000W Laser Cleaner

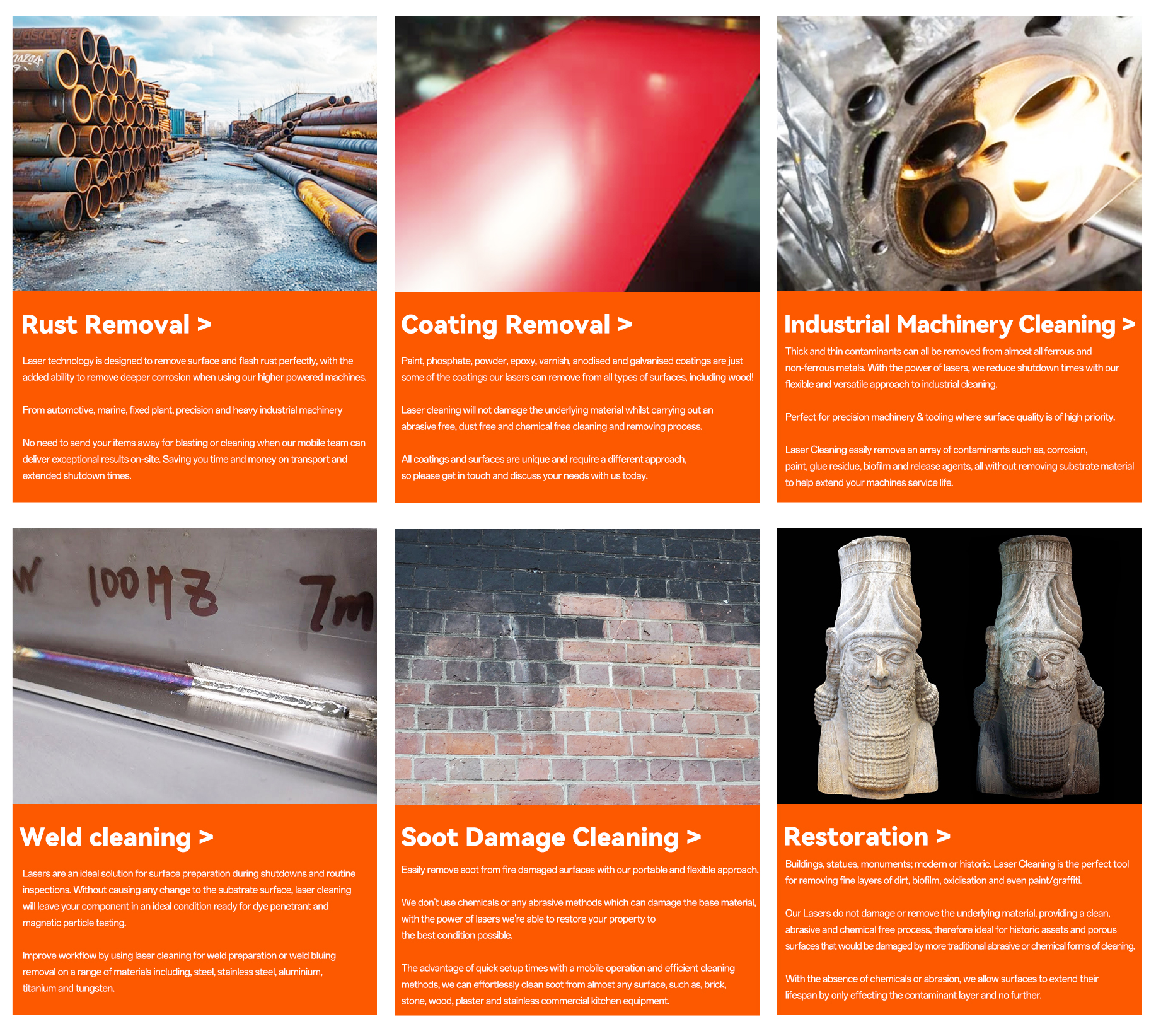

A 2000-watt laser cleaning machine is designed for high-demand, industrial applications. It excels in:

1. Heavy Equipment & Manufacturing

• Cleans factory tools, metal parts, and molds.

• Removes industrial grime, grease, and oxidation.

• Maintains machinery without downtime.

2. Shipbuilding & Marine Industry

• Removes marine rust and corrosionfrom ship hulls.

• Prepares surfaces for coating and painting.

• Reduces downtime for offshore and naval maintenance.

3. Aerospace & Automotive Restoration

• Cleans engine parts, chassis, and metal surfaces.

• Removes oxidation and coatingsfor bonding and welding.

• Increases component lifespan and safety compliance.

4. Infrastructure & Historical Restoration

• Cleans bridges, rail tracks, and pipelines.

• Removes grime from statues, buildings, and sculptures.

• Restores delicate historical artifactswithout abrasives.

The power and efficiency of 2000W laser cleaning make it an essential tool for industries requiring large-scale, precision cleaning.

4. How Much Does a 2000W Laser Cleaner Cost?

The cost of a 2000W laser cleaner depends on factors such as technology, automation level, and cooling system.

Price Range of 2000W Laser Cleaners

| Laser Type | Price Range (USD) | Best For |

|---|---|---|

| Handheld 2000W Laser | $30,000 – $50,000 | Mobile cleaning, workshops |

| Stationary 2000W Laser | $50,000 – $80,000 | Industrial production lines |

| Fully Automated 2000W Laser | $80,000+ | High-speed manufacturing |

What Affects Pricing?

1. Cooling System– Water-cooled models are more expensive but essential for long use.

2. Automation Level– CNC and AI-assisted targeting increase costs but boost efficiency.

3. Portability– Mobile units cost less, while robotic-integrated systems demand higher investment.

4. Software & Control Features– Advanced laser control software adds value but raises prices.

Although the initial investment is high, the long-term savings in labor, consumables, and maintenance costs make it cost-effective over time.

5. Long-Term Benefits of a 2000W Laser Cleaner

Investing in a 2000W laser cleaner delivers substantial economic and operational benefits:

1. Eliminates Recurring Consumable Costs

• No need for sandblasting materials, chemicals, or grinding tools.

• Reduces expenses related to hazardous waste disposal.

2. Boosts Productivity & Reduces Downtime

• Faster cleaningmeans increased work efficiency.

• Less maintenance than traditional abrasive or chemical-based systems.

3. Environmentally Friendly & Compliant

• No toxic waste—meets global environmental standards.

• No airborne dust or hazardous fumes, ensuring a safer workplace.

4. Protects Equipment & Extends Lifespan

• Prevents rust-related damage and deterioration.

• Minimizes wear and tear on machinery and tools.

For companies prioritizing efficiency, sustainability, and long-term cost reduction, a 2000W laser cleaning machine is a smart investment.

6. Choosing the Right 2000W Laser Cleaner

To select the best 2000W laser cleaner for your needs, consider:

1. Cooling System:

° Air-cooled modelsfor short-duration cleaning.

° Water-cooled modelsfor continuous, industrial use.

Automation Level:

° Handheld modelsfor flexible operation.

° CNC-integrated models for high-volume industrial use.

Laser Control & Precision:

° Simple manual controlsfor general cleaning.

° AI-assisted targetingfor delicate, high-precision tasks.

Matching the laser power, cooling, and control system to your specific industry ensures maximum efficiency and ROI.

Final Thoughts: 2000W Laser Cleaners Are Transforming Industrial Cleaning

The 2000W laser cleaner is setting a new standard for industrial rust removal, paint stripping, and surface restoration. It combines unmatched speed, efficiency, and sustainability for automotive, aerospace, manufacturing, marine, and infrastructure industries.

As industries move toward eco-friendly, automated solutions, the 2000W laser cleaning system is becoming the go-to technology for high-performance, industrial-scale cleaning.