Unleashing the Precision of Laser Marking: Transformative Applications Across Industries

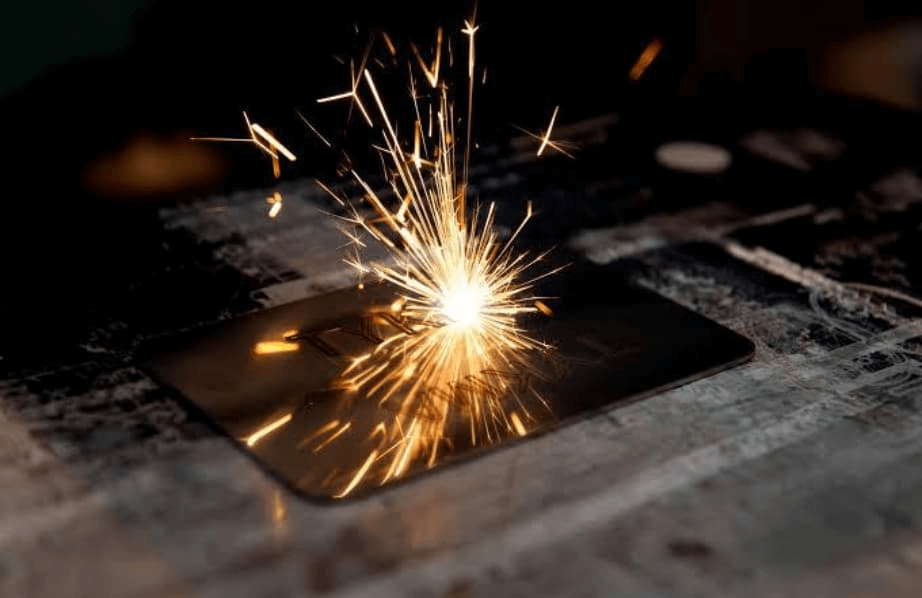

Imagine a world where every product, every component, and every surface can be marked with impeccable precision, unparalleled speed, and unmatched versatility. Picture a single beam of light capable of creating detailed, permanent marks without damaging the material. Welcome to the revolutionary realm of laser marking machines. In this article, we delve into the transformative applications of laser marking technology across various sectors. Whether you are curious about what is laser marking or exploring the benefits of a fiber laser marking machine, this comprehensive guide will illuminate the myriad ways laser marking is changing the game.

Understanding Laser Marking

What is laser marking? Laser marking involves using a focused beam of light to create permanent marks on the surface of materials. This process can include engraving, etching, annealing, and color changing. The technology offers numerous advantages, including high precision, speed, and the ability to mark various materials, from metals to plastics and ceramics. Fiber laser marking machines are a popular choice due to their efficiency and versatility.

The Mechanics of Laser Marking

Laser marking works by directing a high-intensity laser beam at the material’s surface. The energy from the laser alters the material’s properties, resulting in a visible mark. This process is controlled by a computer, allowing for precise, repeatable patterns and designs.

Applications of Laser Marking in Various Industries

Automotive Industry: Driving Precision and Traceability

The automotive industry leverages laser marking technology to enhance precision and traceability:

- Component Identification: Laser marking machines are used to mark serial numbers, barcodes, and logos on automotive components. This ensures easy identification and traceability throughout the supply chain.

- Compliance and Safety: Marking parts with fiber laser marking machines ensures compliance with industry regulations and safety standards. Permanent marks are resistant to wear and environmental conditions, maintaining legibility over time.

- Customization and Aesthetics: Laser marking allows for the customization of interior and exterior car parts, enhancing aesthetic appeal and adding unique branding elements.

Aerospace Industry: Ensuring Reliability and Safety

In the aerospace industry, where safety and reliability are paramount, laser marking is essential:

- Part Identification: What is laser marking used for in aerospace? It’s used to mark essential information on parts, such as serial numbers, batch numbers, and manufacturer details, ensuring traceability and quality control.

- Durability: The marks created by fiber laser marking machines are highly durable, withstanding extreme temperatures, corrosion, and other harsh conditions encountered in aerospace environments.

- Regulatory Compliance: Laser marking helps meet stringent aerospace industry regulations, ensuring that all parts are properly identified and traceable.

Medical Device Manufacturing: Precision and Sterility

The medical device industry demands the highest standards of precision and cleanliness, making laser marking an ideal solution:

- Surgical Instruments: Laser marking machines are used to engrave serial numbers, logos, and other identifiers on surgical instruments. The precision of laser marking ensures clear, legible marks that do not affect the instrument’s performance.

- Implants and Prosthetics: Marking implants and prosthetics with fiber laser marking machines ensures permanent identification without compromising biocompatibility.

- Regulatory Compliance: The medical device industry requires strict adherence to traceability standards. Laser marking provides the precision needed to comply with these regulations, ensuring every device can be tracked and identified.

Electronics Industry: Enhancing Quality and Traceability

The electronics industry relies on laser marking for its ability to produce detailed, permanent marks on small components:

- PCB Marking: What is laser marking used for in electronics? It’s used to mark printed circuit boards (PCBs) with critical information such as serial numbers, batch numbers, and logos. The precision of laser marking ensures marks are clear and do not interfere with the PCB’s function.

- Component Identification: Laser marking is employed to mark various electronic components, ensuring they can be easily identified and traced throughout the production process.

- Miniaturization: The precision of fiber laser marking machines allows for marking on miniature components, which is essential as electronic devices continue to shrink in size.

Jewelry Making: Crafting with Elegance and Precision

The jewelry industry has adopted laser marking for its ability to create intricate designs and detailed markings:

- Custom Engravings: Laser marking machines enable jewelers to create custom engravings with fine details, enhancing the uniqueness and personalization of jewelry pieces.

- Hallmarking: Laser marking is used to apply hallmarks and other identifying marks on precious metals, ensuring authenticity and compliance with industry standards.

- Repair and Restoration: Laser marking allows for seamless repair and restoration of jewelry, maintaining the original appearance and value.

Manufacturing Industry: Streamlining Production and Quality Control

The manufacturing sector utilizes laser marking to improve efficiency and maintain high-quality standards:

- Traceability: Fiber laser marking machines are used to mark products with serial numbers, barcodes, and other identifiers, ensuring full traceability throughout the production process.

- Quality Control: Laser marking provides a reliable method for marking inspection and quality control data on products, ensuring consistency and reliability.

- Brand Enhancement: Manufacturers use laser marking to add logos and branding elements to their products, enhancing brand recognition and value.

Renewable Energy: Marking for Efficiency and Sustainability

The renewable energy sector benefits from laser marking technology to ensure the efficiency and longevity of energy systems:

- Solar Panel Identification: Laser marking machines are used to mark solar panels with essential information, ensuring traceability and compliance with industry standards.

- Wind Turbine Components: Laser marking provides durable, legible marks on wind turbine components, ensuring they can withstand harsh environmental conditions.

- Battery Storage Systems: Marking battery storage components with fiber laser marking machines ensures reliable identification and traceability, enhancing system performance and maintenance.

Advantages of Laser Marking

- Precision and Accuracy: Laser marking offers unmatched precision, allowing for detailed and intricate designs with high accuracy.

- Durability: The marks created by laser marking are permanent and resistant to wear, ensuring long-lasting legibility.

- Versatility: Laser marking can be used on a wide range of materials, including metals, plastics, ceramics, and more.

- Speed and Efficiency: Laser marking is faster than traditional methods, reducing production time and increasing efficiency.

- Eco-Friendly: Laser marking is a clean process that does not involve harmful chemicals, making it environmentally friendly.

Conclusion: The Future of Marking

The applications of laser marking are vast and varied, spanning industries from automotive to aerospace, medical devices to jewelry making. As technology continues to advance, the precision, efficiency, and versatility of laser marking will only improve, solidifying its place as the marking method of the future. Whether you are exploring what is laser marking for your industry or seeking the best fiber laser marking machine for your needs, the benefits are clear.

By adopting laser marking technology, companies can achieve higher precision, efficiency, and quality in their production processes. This not only enhances product traceability and compliance but also contributes to a cleaner, greener future. As more industries recognize the advantages of laser marking, its applications will continue to expand, driving innovation and setting new standards in marking technology.