Redefining Clean: The Revolutionary Portable Laser Cleaning Machine

Imagine a world where cleaning isn’t a chore, but a technological marvel—a world where stubborn rust, paint, and contaminants vanish in an instant. Enter the portable laser cleaning machine: a tool so powerful, precise, and eco-friendly that it’s transforming industries across the globe. Compact yet mighty, these machines bring unparalleled convenience and efficiency to industrial cleaning tasks. With CQX leading the charge, this innovative technology is making its mark everywhere, from automotive repair shops to heritage restoration projects.

1. The Evolution of Cleaning Technology

From Arc to Laser: A Paradigm Shift

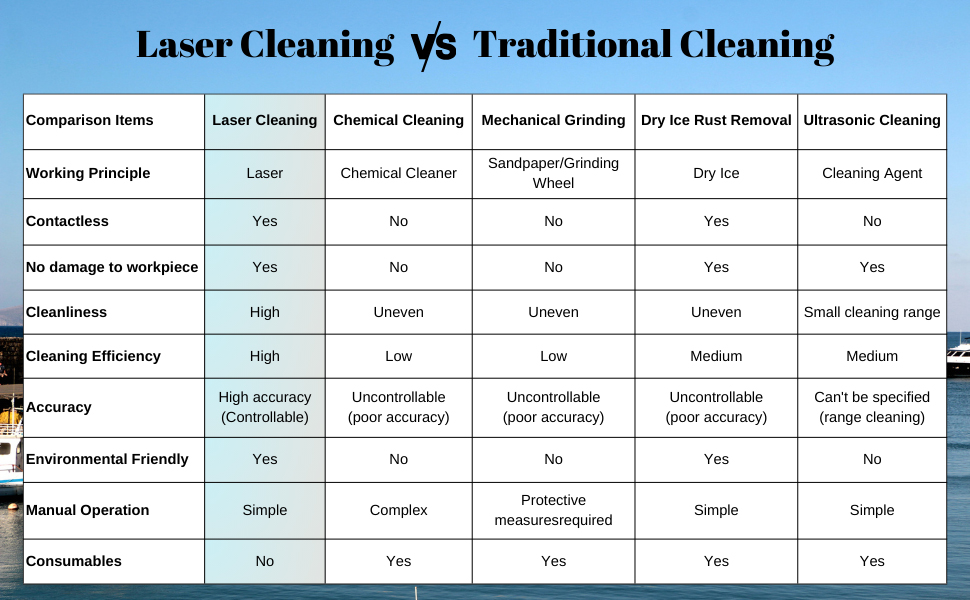

Cleaning techniques have come a long way. Sandblasting, chemical treatments, and manual scrubbing have been staples for years. However, these methods are often labor-intensive, harmful to materials, and environmentally damaging. Laser cleaning represents a significant leap forward, providing a non-contact, residue-free solution.

The Role of Laser Technology in Cleaning

Laser cleaning uses high-energy laser pulses to remove surface contaminants without damaging the base material.

This precision makes it ideal for delicate surfaces and applications requiring exceptional cleanliness.

2. Key Features of Portable Laser Cleaning Machines

Portability and Flexibility

Unlike traditional cleaning systems, portable laser cleaning machines are lightweight and easy to transport, making them perfect for on-site applications.

Their compact design allows access to tight spaces and hard-to-reach areas.

Precision Cleaning

The laser’s adjustable beam ensures targeted cleaning, removing contaminants without harming the underlying material. This precision is especially useful for sensitive surfaces like antique sculptures or aerospace components.

Eco-Friendly Technology

With no need for chemicals or abrasives, portable laser cleaning machines align with sustainable practices. They produce minimal waste and reduce environmental impact.

User-Friendly Design

Modern machines feature intuitive interfaces, allowing operators to adjust settings easily for different materials and contamination levels.

3. Applications of Portable Laser Cleaning Machines

Automotive Industry

Rust removal, paint stripping, and degreasing engine parts are just a few automotive applications.

Portable laser cleaning machines streamline these processes, saving time and ensuring high-quality results.

Aerospace Maintenance

The aerospace sector requires meticulous cleaning standards. Laser cleaning provides precision and consistency, ensuring that components meet rigorous safety and performance requirements.

Restoration of Historical Artifacts

Restoring historical artifacts demands careful handling to preserve their integrity. Portable laser cleaning machines can remove dirt, rust, and grime without damaging fragile surfaces.

Industrial Equipment Maintenance

In factories and workshops, cleaning machinery and tools is crucial for maintaining efficiency. Laser cleaning removes grease, oil, and residue quickly, minimizing downtime.

Marine Applications

Ships and marine equipment are constantly exposed to saltwater, leading to corrosion.

Laser cleaning provides a fast and effective way to remove rust and scale from ship surfaces and marine equipment.

4. Advantages Over Traditional Cleaning Methods

Non-Destructive Cleaning

Unlike abrasive methods, laser cleaning doesn’t damage the base material. This makes it ideal for applications requiring precision and care.

Cost-Effective

Although the initial investment may be high, laser cleaning machines save money in the long run by reducing labor, consumables, and maintenance costs.

Improved Worker Safety

Laser cleaning eliminates the need for hazardous chemicals, protecting workers from exposure to harmful substances.

High Efficiency

The speed and precision of laser cleaning ensure faster project completion compared to traditional methods.

5. Innovations in Portable Laser Cleaning Technology

Adjustable Power and Frequency

Modern machines allow users to customize laser power and frequency for optimal cleaning results on different materials.

AI Integration

Artificial intelligence is being integrated into laser cleaning machines, enabling automatic adjustments based on material type and contamination level.

Enhanced Portability

Innovations in design have made these machines even lighter and more compact, further increasing their usability in diverse environments.

6. Best Practices for Using Portable Laser Cleaning Machines

Safety Precautions

Operators should wear appropriate protective gear, including laser safety glasses, to prevent exposure to laser beams.

Material Assessment

Before cleaning, assess the material to determine the appropriate laser settings. Different surfaces may require varying power levels.

Regular Maintenance

Keep the machine in optimal condition by cleaning lenses and checking for wear and tear on components.

7. CQX Portable Laser Cleaning Machines: A Benchmark for Excellence

CQX has set a new standard in the industry with its cutting-edge portable laser cleaning machines. Designed for versatility and efficiency, these machines cater to a wide range of applications, delivering unmatched results. With a commitment to innovation and sustainability, CQX ensures that its products meet the highest standards of quality and performance.

8. Future Prospects of Laser Cleaning Technology

Expanding Applications

As laser cleaning technology evolves, its applications are expected to expand into new industries, including electronics manufacturing and renewable energy.

Increased Automation

Automation and AI will likely play a larger role in laser cleaning, improving efficiency and reducing the need for manual intervention.

Sustainable Manufacturing

With its eco-friendly design, laser cleaning will become an integral part of sustainable manufacturing practices worldwide.

9. Common Questions About Portable Laser Cleaning Machines

Q: How does laser cleaning compare to sandblasting?

A: Laser cleaning is more precise, eco-friendly, and non-destructive, whereas sandblasting can damage materials and create significant waste.

Q: Can portable laser cleaning machines handle large-scale projects?

A: Yes, portable machines are versatile and powerful enough for both small and large-scale applications.

Q: Are these machines easy to operate?

A: Most modern laser cleaning machines, including those by CQX, feature user-friendly interfaces for ease of operation.

Q: What types of contaminants can laser cleaning remove?

A: Laser cleaning effectively removes rust, paint, grease, oil, and other surface contaminants.

Closing Thoughts

The portable laser cleaning machine is more than just a tool—it’s a technological marvel redefining the cleaning process. Its precision, efficiency, and eco-friendliness make it an essential asset across various industries. As CQX continues to innovate and refine its products, the potential applications of portable laser cleaning machines are virtually limitless. Whether for restoring priceless artifacts or maintaining industrial equipment, this groundbreaking technology is paving the way for a cleaner, greener, and more efficient future.